Veris Industries Badger 3050 SERIES Install User Manual

Page 5

5

for a wide variety of custom RTD’s and thermistors. Refer

to Programming Flow Charts. Contact the factory for

assistance for any custom inputs.

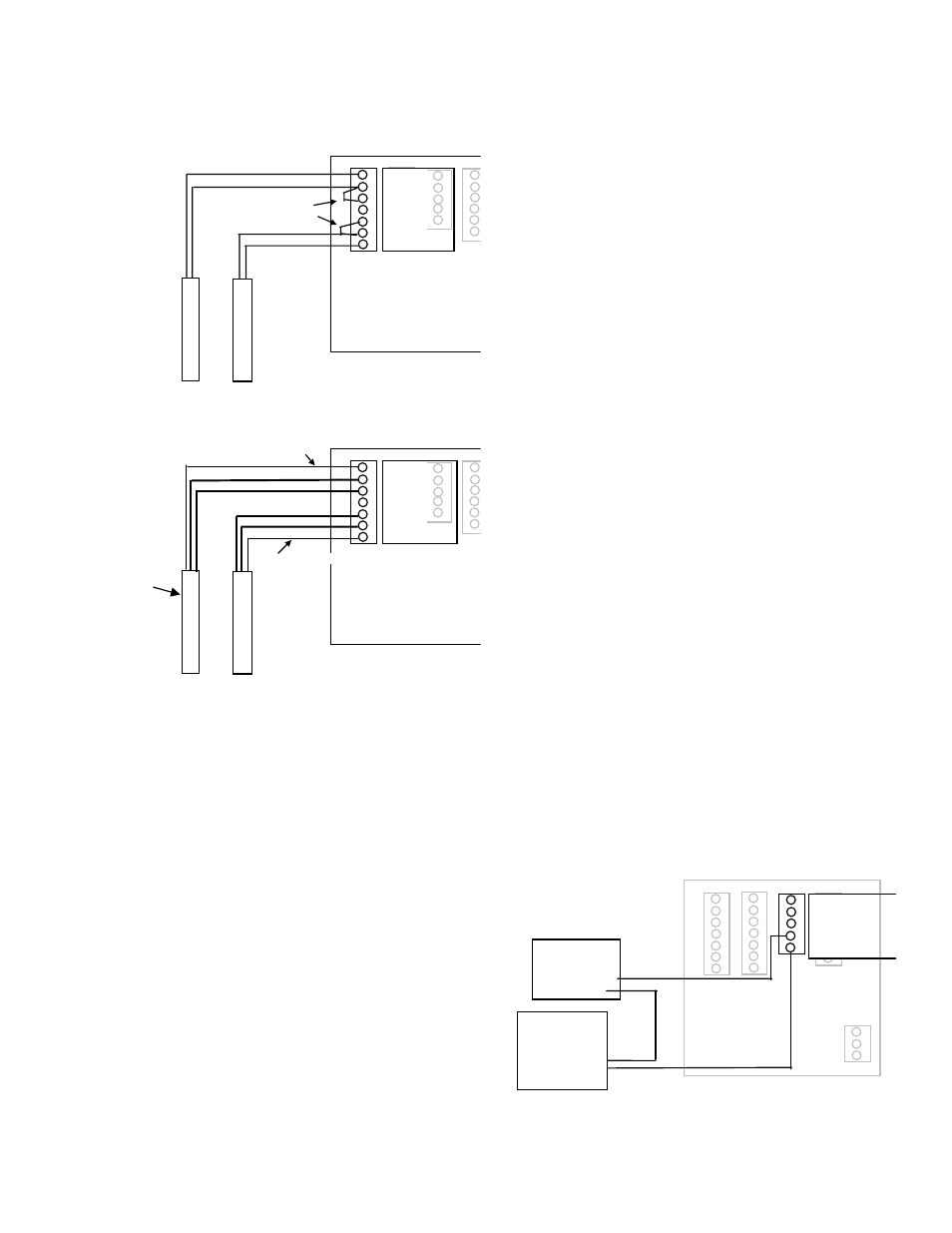

Wiring Two Wire Thermistors and RTD’s

Wiring Two Wire Thermistors and RTD’s

Wiring Three Wire RTD’s

1 TEMP 1 IN +

2 TEMP 1 IN -

3 TEMP 1 GND

4 SHIELD

5 TEMP 2 GND

6 TEMP 2 IN -

7 TEMP 2 IN +

Jumpers

2 Wire

Thermistor

Located

in same

Supply

or

Return line

Flow Sensor

2 Wire

Thermistor

3 Wire

RTD

T1

Located

in same

Supply

or

Return line

as

Flow Sensor

3 Wire

RTD

Same Colored 2 Wires

Different Color Wire

Different Wire

1 TEMP 1 IN +

2 TEMP 1 IN -

3 TEMP 1 GND

4 SHIELD

5 TEMP 2 GND

6 TEMP 2 IN -

7 TEMP 2 IN +

Wiring Three Wire RTD’s

Wiring Two Wire Thermistors and RTD’s

Wiring Three Wire RTD’s

1 TEMP 1 IN +

2 TEMP 1 IN -

3 TEMP 1 GND

4 SHIELD

5 TEMP 2 GND

6 TEMP 2 IN -

7 TEMP 2 IN +

Jumpers

2 Wire

Thermistor

Located

in same

Supply

or

Return line

Flow Sensor

2 Wire

Thermistor

3 Wire

RTD

T1

Located

in same

Supply

or

Return line

as

Flow Sensor

3 Wire

RTD

Same Colored 2 Wires

Different Color Wire

Different Wire

1 TEMP 1 IN +

2 TEMP 1 IN -

3 TEMP 1 GND

4 SHIELD

5 TEMP 2 GND

6 TEMP 2 IN -

7 TEMP 2 IN +

solid state switch and Form “C” Output Wiring

The Badger® Data Industrial® Series 3050 has one

Normally Open (N.O.) solid state switch, and one Solid

State Form “C” Relay. Check the specifications page

for maximum voltage and current ratings for each type

output.

These outputs are completely independent, electrically

isolated, and can be programmed as either Pulse, or Set-

point outputs.

When the function “Totalizer” is selected the unit of

measure and resolution are independent from the

displayed units, and can be programmed where 1 pulse

occurs once every 0000000.1 to 999999999.of units

selected, with any pulse width from 0001 to 9999mS.

When the “Alarm” is selected the unit of measure and

the resolution is independent from the displayed units,

it allows the unit to be programmed as either a High or

Low rate Set Point. Since the Set-point, Release Point,

and there associated time delays are fully independent

this output can be either a classical High Rate, or Low

Rate alarm depending on the settings selected. When

design-planning keep in mind that although both of these

outputs can be programmed as alarm points only the

Relay provides both N.O. and N.C. contacts. The switch

is a simple N.O. contact.

Examples:

High set-Point Control

The Set-Point “SETPT” must be a value greater than the

Release Point “RELP.”

The Relay output will have continuity between its “N.C”.

terminal and “COM” until the flow has exceeded the

Set-Point “SETPT” for a continuous period of time

exceeding the Set-Point-Delay “SDLY”, at which time

the N.C. connection with open, and the N.O. contact

will have continuity to the “COM” terminal. When the

flow has dropped below the Release Point “RELP” for a

continuous period of time exceeding the “RDLY” the relay

states will return to there original states. If the Latch has

been set to “ON” once the set-point and set-delay have

been satisfied the relay will not release until manually

reset. Sources for the Set-Point Control can be Flow

Rate, Energy Rate, T1, T2, or Delta T.

low set-Point Control

The Set-Point “SETPT” must be a value less than the

Release Point “RELP.”

The Relay output will have continuity between its

“N.C”. terminal and “COM” until the flow drops below

the Set-Point “SETPT” for a continuous period of time

exceeding the Set-Point-Delay “SDLY”, at which time

the N.C. connection with open, and the N.O. contact will

have continuity to the “COM” terminal. When the flow

has again risen above the Release Point “RELP” for a

continuous period of time exceeding the “RDLY” the relay

states will return to there original states. If the Latch has

been set to “ON” once the set point and set-delay have

been satisfied the relay will not release until manually

reset. Sources for the Set-Point Control can be Flow

Rate, Energy Rate, T1, T2, or Delta T.

Figure 7

Relay and Switch Wiring Examples

Mechanical

Counter

(+)

(-)

Power Supply

(Appropriate for

Counter ratings)

(-)

(+)

1 RELAY 1 NO

2 RELAY 1 NC

3 RELAY 1 COM

4 PULSE 1 OUT

5 PULSE 2 OUT

Figure 7

Relay and switch Wiring Examples