Veris Industries Badger 3050 SERIES Install User Manual

Page 2

2

Table of Contents

Introduction ...................................................................... 2

Installation ....................................................................... 2

Electrical Installation ........................................................ 3

Programming ................................................................... 6

Specifications ................................................................ 14

INTRODUCTION

The Badger® Data Industrial® 3050 Energy Monitor is

an economical full-featured compact unit designed for

sub-metering applications. The two line x 16 character

alphanumeric displays any combination of Energy

Rate, Energy total, Flow Rate or Flow Total. Both pre-

programmed and user defined units of measure can be

configured by the user.

The Series 3050 accepts pulse, sine wave, or linear

analog input signals. Like all Data Industrial flow

monitors, the Series 3050 may be field calibrated by

the user. For Data Industrial sensors “K” and “offset”

numbers are entered, while other pulse or frequency

output sensors may use a “K” factor only. Analog inputs

are fully programmable for slope and intercept.

The unit requires two temperature units and can accept

10 K ohm thermistors, 100Ώ Three Wire RTD’s or user

defined custom thermistors or RTD’s.

The panel meter has a NEMA 4X rated front panel and

conforms to DIN Standard dimensions,

96 mm X 96 mm, for meter sizes and panel cutouts.

Optional NEMA 4 wall mount also available.

The user can program the flow sensor from the front

panel by entering a "K" and offset or only a "K" factor,

depending on the flow sensor used.

Programming is menu driven. All data is entered using

the LCD/keypad interface. A password gate is included

to prevent unauthorized access to programming

parameters. Programming flexibility is extended to

units of measure. In addition to several factory units of

measure, the Series 3000 software permits the custom

units for rate and total to be created by the installer.

The Series 3050 provides one Form C solid-state

relay, and one solid-state switch output. Both are fully

programmable as either Pulse/Volume, or Set-point

control based Flow Rate, Flow Total, Energy Rate,

Energy Total, Temperature 1, Temperature 2, or Delta

T. For pulse output, the installer can program both the

resolution, and the pulse width. Set-Point control is

extremely versatile with fully independent set and release

points each with its own time delay.

LED’s located on the front panel indicate status of both

the Relay and Pulse Outputs.

All calibration information, units of measure and flow

totals are stored in a non-volatile memory that does not

require battery backup for data retention.

Options available:

• Analog Output

• USB

• RS485

• BACnet

• Modbus

• Wall Mounting

INsTallaTION

Mechanical Installation:

The Series 3050 can be either panel mounted or wall

mounted.

location:

In any mounting arrangement the primary concern is

easy viewing, and convenient operation of the keypad.

The unit generates very little heat, so no consideration

need be given to cooling. However, prolonged direct

sunlight can damage the front panel so some level of

shading is recommended, especially if installed in a

tropical climate.

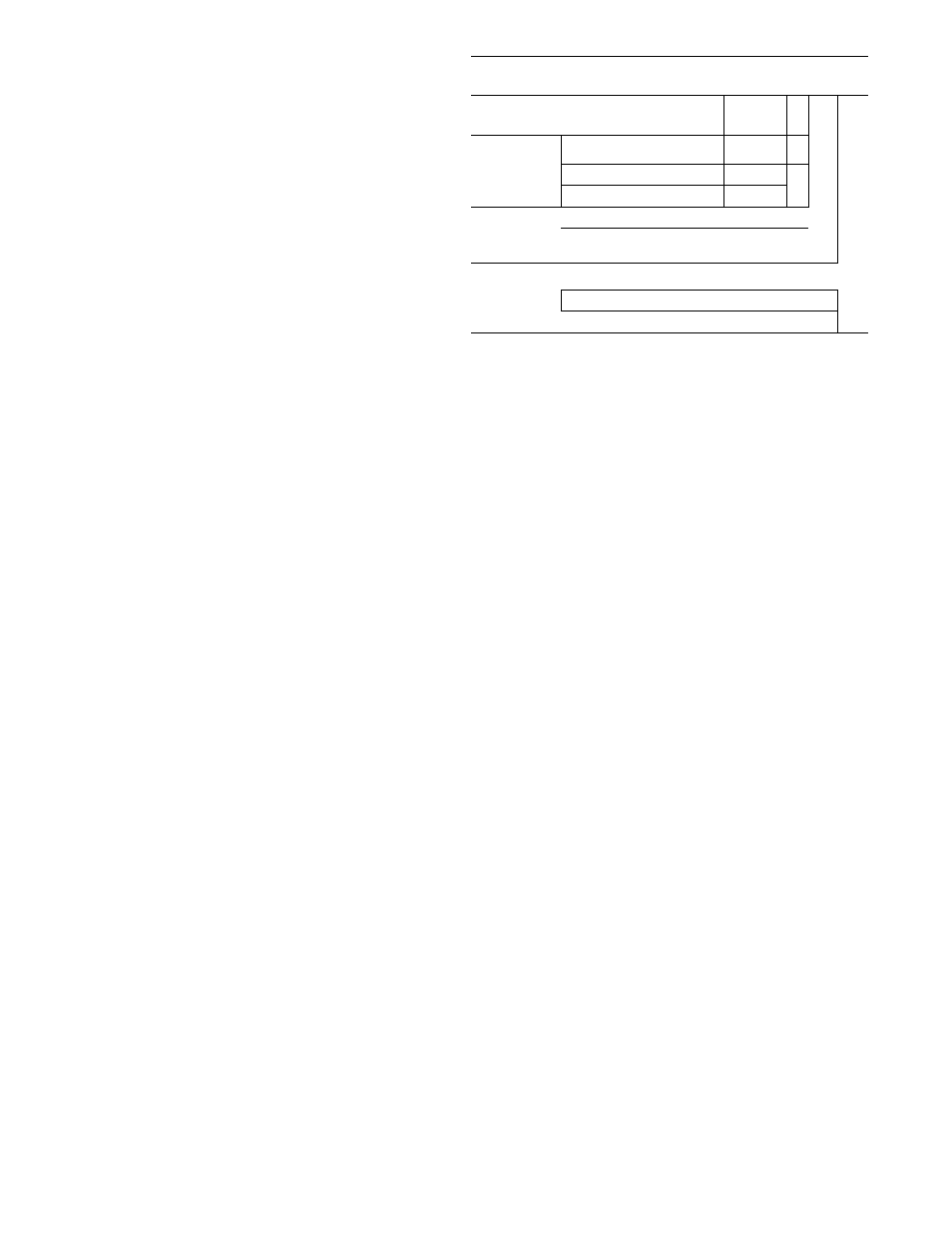

Panel Mount Installation

The Model 3050 Panel Mount is designed for through

panel mounting, which allows access to the back of

the unit. The 3050 is secured to the panel by two draw

brackets shown in Figure 1 on the next page. Refer to

Figure 1 for flow monitor and panel cutout dimensions.

Wall Mount Installation

The Badger® Data Industrial® Model 3050 Wall Mount is

designed to mount onto a wall with four bolts or screws.

The mounting hole pattern and box dimensions for the

Model 3050 NEMA 4 waII mount are shown in Figure 2.

3050 Series Ordering Matrix

Example: 3050 - x x

Series

Btu Monitor

3050 -

Outputs

No Option

0

Analog Output, plus RS485 with

BACnet and Modbus, and USB

1

Mounting

Panel Mount, NEMA 4x Front Panel

0

Wall Mount, NEMA 4x

1

Figure 1: Panel Mounting Dimensions