Veris Industries Badger 3050 SERIES Install User Manual

Page 4

4

Flow sensor Wiring

The Badger® Data Industrial® Series 3050 Flow Sensor

Inputs are extremely versatile, designed to accept either

two wire or three wire pulse inputs (Data Industrial 200

Series, SDI, or 4000 Series), zero crossing sine wave

inputs, or Analog inputs. Although different rear panel

terminals are used, all parameters are set with the LCD/

keypad interface. There are no internal or external

jumpers, switches, or potentiometers to move or adjust.

Four types of Pulse Input Types are accommodated.

Pulse-DI: Used for all Badger Data Industrial Flow

1.

Sensors.

Provides an internal Pull-Up resistor and uses “K”

and “Offset” values for calibration.

Pulse –K Factor:

2.

Accepts non Zero Crossing inputs but provides no

internal pull-up, classical “K” ( Pulses/Gal) values for

calibration.

Pullup-K Factor:

3.

Provides an internal Pull-Up resistor and uses

classical “K” ( Pulses/Gal) values for calibration.

Sine-K Factor:

4.

Accepts Zero Crossing low voltage sourcing devices,

with classical “K” ( Pulses/Gal) calibration.

all the above wire the same as shown in Figure 4.

see Programming Flow Chart for required input

configuration.

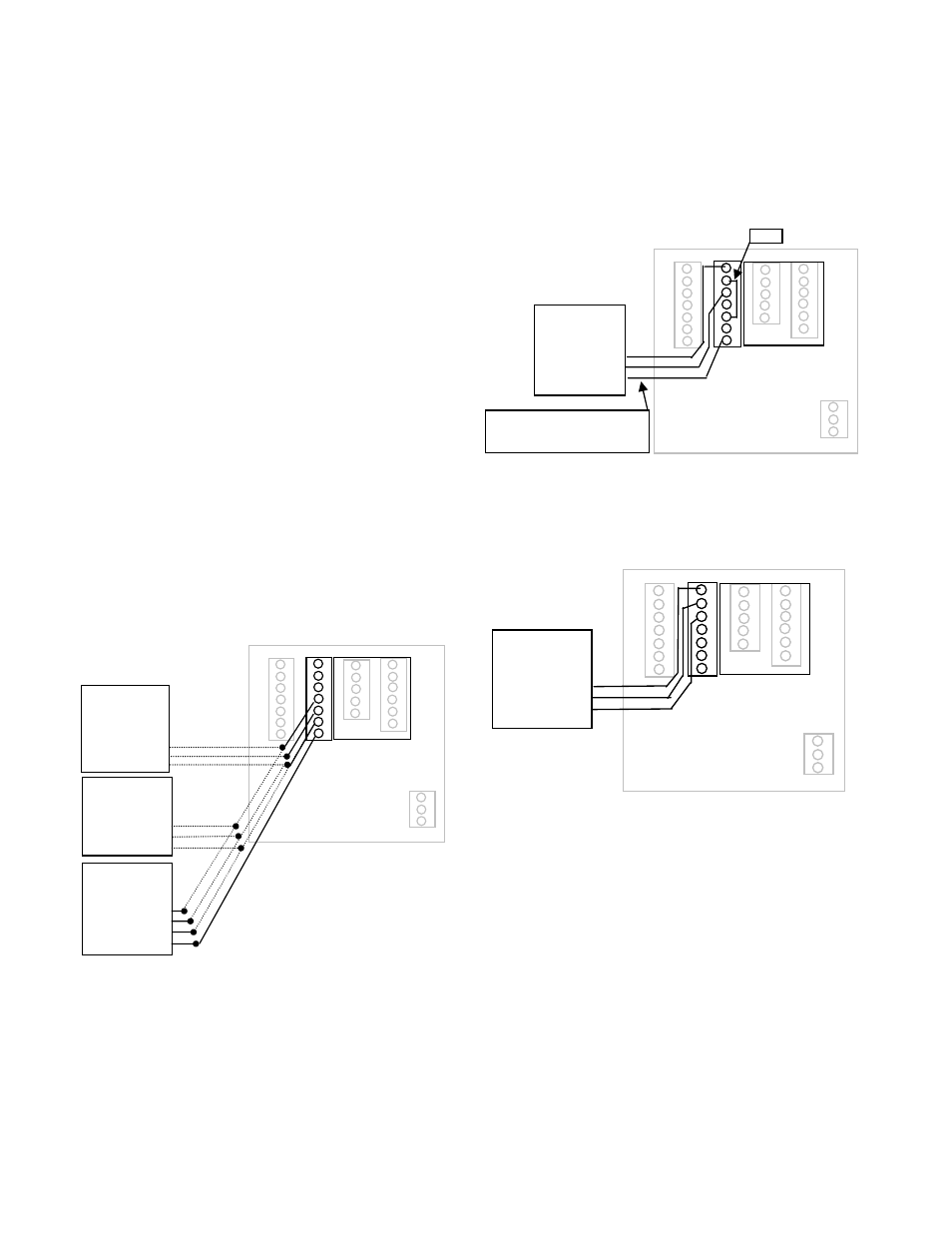

Figure 4

Data industrial Flow Sensor Wiring Examples

(Two and Three Wire Pulse Types)

Figure 5

4-20mA Analog Loop Powered Wiring

Figure 6

Voltage or Current Sourcing Analog Inputs

Two Wire

Flow Sensor

200 Series

Red

Black

Shield

Two Wire

Flow Sensor

SDI

3. Signal

2. Common

1. Shield

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Three Wire

Flow Sensor

4000 Series

White

Black

Shield

Red

Two Wire

Analog Sensor

9.5V Max@20mA

Loop -

Shield

Loop +

Jumper

Note:

If sensor requires more than 9.5VDC at

20mA -Use a separate 24VDC supply.

Voltage or Current

Sourcing

Device

V+

V-

Shield

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Figure 4

Data industrial Flow sensor Wiring Examples

(Two and Three Wire Pulse Types)

analog Input

As an alternative to the Pulse Inputs the Series 3050

can accept a Analog input. The input is non-isolated,

but can accept 0-1VDC ; 0-5VDC; 0-10VDC; 0-20mA;

and 4-20mA with both factory defined, and custom units

of measure. Low impedance 100 Ohm input for current

inputs optimizes performance and flexibility or loop

power supplies. Both the Low and High end scaling are

independent, and field configured by the installer.

see Programming Flow Chart for required input

configuration.

analog Flow sensor Input Wiring

Figure 4

Data industrial Flow Sensor Wiring Examples

(Two and Three Wire Pulse Types)

Figure 5

4-20mA Analog Loop Powered Wiring

Figure 6

Voltage or Current Sourcing Analog Inputs

Two Wire

Flow Sensor

200 Series

Red

Black

Shield

Two Wire

Flow Sensor

SDI

3. Signal

2. Common

1. Shield

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Three Wire

Flow Sensor

4000 Series

White

Black

Shield

Red

Two Wire

Analog Sensor

9.5V Max@20mA

Loop -

Shield

Loop +

Jumper

Note:

If sensor requires more than 9.5VDC at

20mA -Use a separate 24VDC supply.

Voltage or Current

Sourcing

Device

V+

V-

Shield

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Figure 5

4-20ma analog loop Powered Wiring

Figure 4

Data industrial Flow Sensor Wiring Examples

(Two and Three Wire Pulse Types)

Figure 5

4-20mA Analog Loop Powered Wiring

Figure 6

Voltage or Current Sourcing Analog Inputs

Two Wire

Flow Sensor

200 Series

Red

Black

Shield

Two Wire

Flow Sensor

SDI

3. Signal

2. Common

1. Shield

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Three Wire

Flow Sensor

4000 Series

White

Black

Shield

Red

Two Wire

Analog Sensor

9.5V Max@20mA

Loop -

Shield

Loop +

Jumper

Note:

If sensor requires more than 9.5VDC at

20mA -Use a separate 24VDC supply.

Voltage or Current

Sourcing

Device

V+

V-

Shield

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

1 ANALOG IN+

2 ANALOG IN-

3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Figure 6

Voltage or Current sourcing analog Inputs

TEMPERaTURE INPUT:

The Badger

®

Data Industrial

®

Series 3050 can accept

inputs from either a pair of thermistors or RTD’s. The

inputs are labeled T1 and T2. Since the T1 sensor is

used to convert the volumetric flow (Example: GPM)

to the mass flow ( Example: Lbs/Hr) used in the Btu

Calculations, the sensor connected to T1 should be in the

same supply or return line as the Flow Sensor.

The temperature inputs of the 3050 are extremely

versatile. In addition to the factory default two wire10k

@77°F Type II Thermistors, and three wire 100 ohm

Platinum RTD’s, the unit can be programmed in the field