Replacing the o-ring seals, Figure 10, Adapter for catalyst cartridge with handle – M&C TechGroup CG-2H-W_-2MH-W Operator's manual User Manual

Page 23

23

Gas sampling and conditioning technology

9-0.2-ME

against unauthorised access!

Turn the closing cap/adapter with handle (see figures 4 and 5) counter-clockwise.

Pull the catalyst cartridge at the closing cap with a rotary motion out of the adapter;

The re-inserting has to be done in the opposite way.

N O T E !

In order to obtain the required gas-tightness, take care that the

cartridge is always inserted into the adapter right up to the stop.

Moisten the outer O-rings helps placing the cartridge into the

oven.

Do not use grease for O-rings because it could affect the effi-

ciency of the catalyst !

N O T E !

After mounting a new catalyst cartridge an initial running of

approx. 2 hours is necessary to get stable CO and NO

X

values.

17.2

REPLACING THE O-RING SEALS

We also recommend replacing the adapter's seals every time that the cartridge is replaced.

W A R N I N G !

Hot catalyst cartridges. Touching the cartridge can lead to very

severe burns. Wear protective gloves and safeguard cartridge

against unauthorised access!

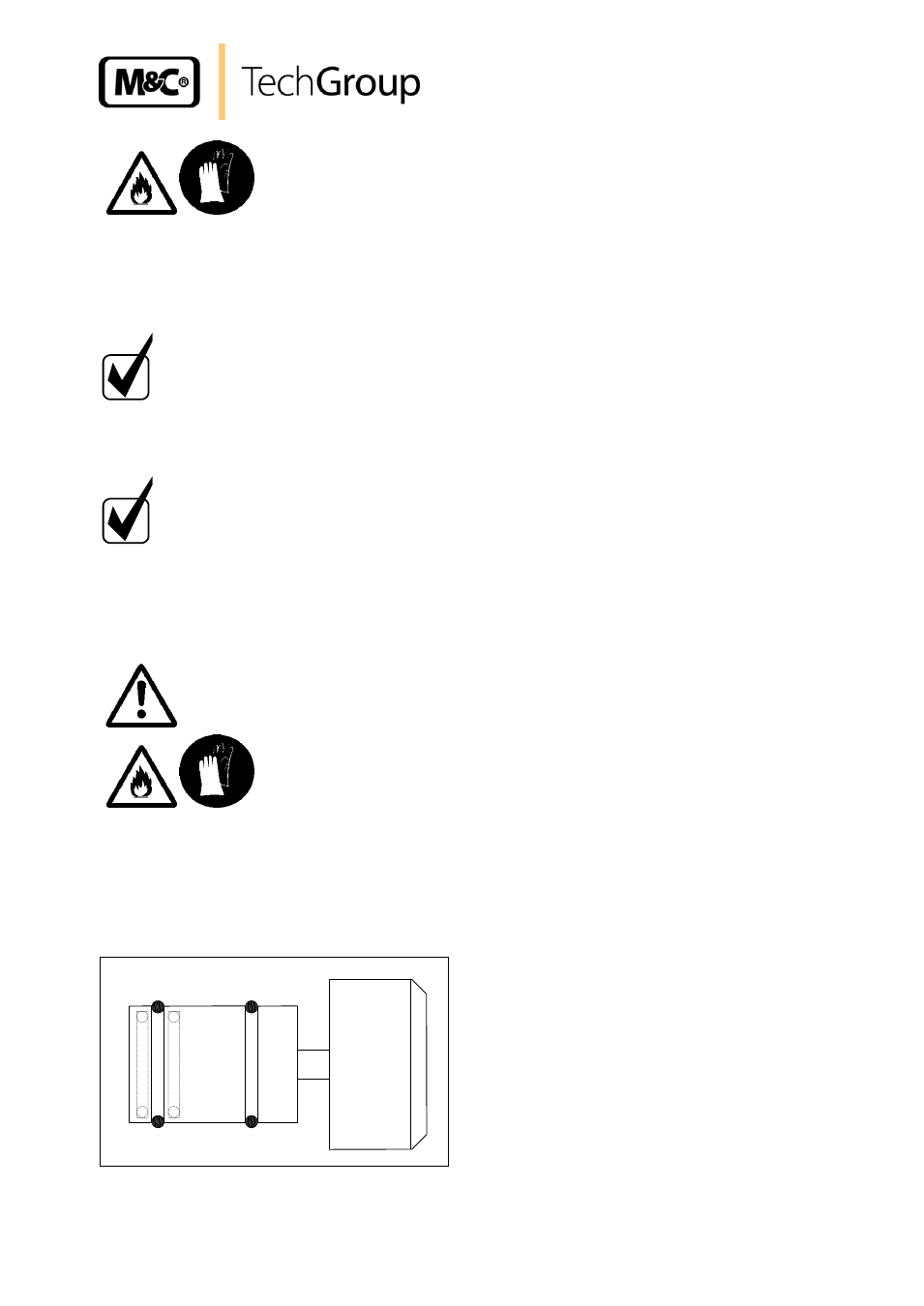

Figure 10 shows schematically the location of the two inside and outside O-ring seals.

Figure 10

Adapter for catalyst cartridge with handle

The inside seals can be removed using a pointed tool

(e.g. a needle).