M&C TechGroup PMA 100-L Operator's manual User Manual

Page 6

M&C Products Analysentechnik GmbH

9-3.12.1-ME

- 6 -

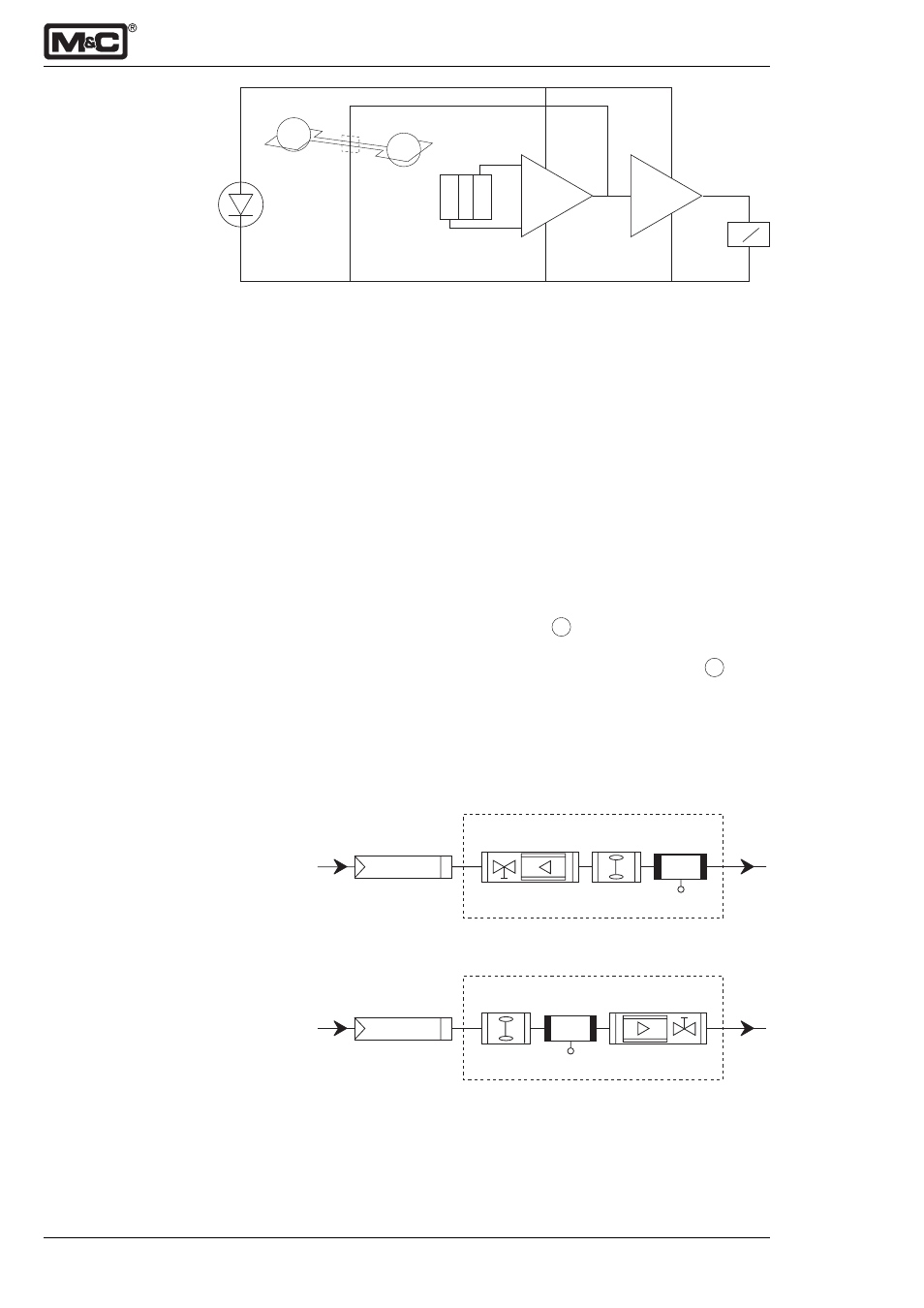

the corresponding output of the amplifier, which is a current

and also proportional to the oxygen content, produces a

magnetic field in the feedback coil opposing the forces and

thereby causing the dumb bell to rotate.

Since the feedback current from the amplifier is proportio-

nal to the oxygen content of the gas sample, the output

signals produced by the amplifier will be accurate and

linear. The paramagnetic susceptibility of oxygen varies

inversely as the square of the absolute temperature. There-

fore, a temperature sensitive element in contact with the

measuring cell assembly is included in the feedback

current circuit in order to provide compensation for

changes in analyser temperature.

7.2

Flow diagram

The flow can be adjusted in a range of 25 - 60Nl/h air at the

flowmeter with needle valve 2 built on the front panel of

the analyser.

The flow sensor at the outlet of the measuring cell 3 de–

tects the sample flow if it decreases under 25l/hr.

We recommend a conditioning system upstream the

analyser PMA100-L, f.e. consisting of a cooler and fine

filter.

We like to inform you about suitable M&C equipment.

1:

Measuring cell

2:

„LED“ light beam

3:

Photo cell

4:

Feed back amplifier

5:

Output amplifier

6:

Meter indication

Fig. 3:

Principle of operation

PMA100-L

1: external filter

2: flowmeter with needle valve

3: patented M&C measuring cell PMA100-L

4: flow control

Fig. 4:

Flow diagram of the analyser

1

2

3

4

➞ ➞

1

2

3

5

4

6

PMA100-LF

1: external filter

2: flowmeter with needle valve

3: patented M&C measuring cell PMA100-L

4: flow control

1

3

4

2