Trouble shooting – M&C TechGroup ECM-ExII Operator's manual User Manual

Page 22

22

Gas sampling and gas conditioning technology

3-3.0EX-ME

20

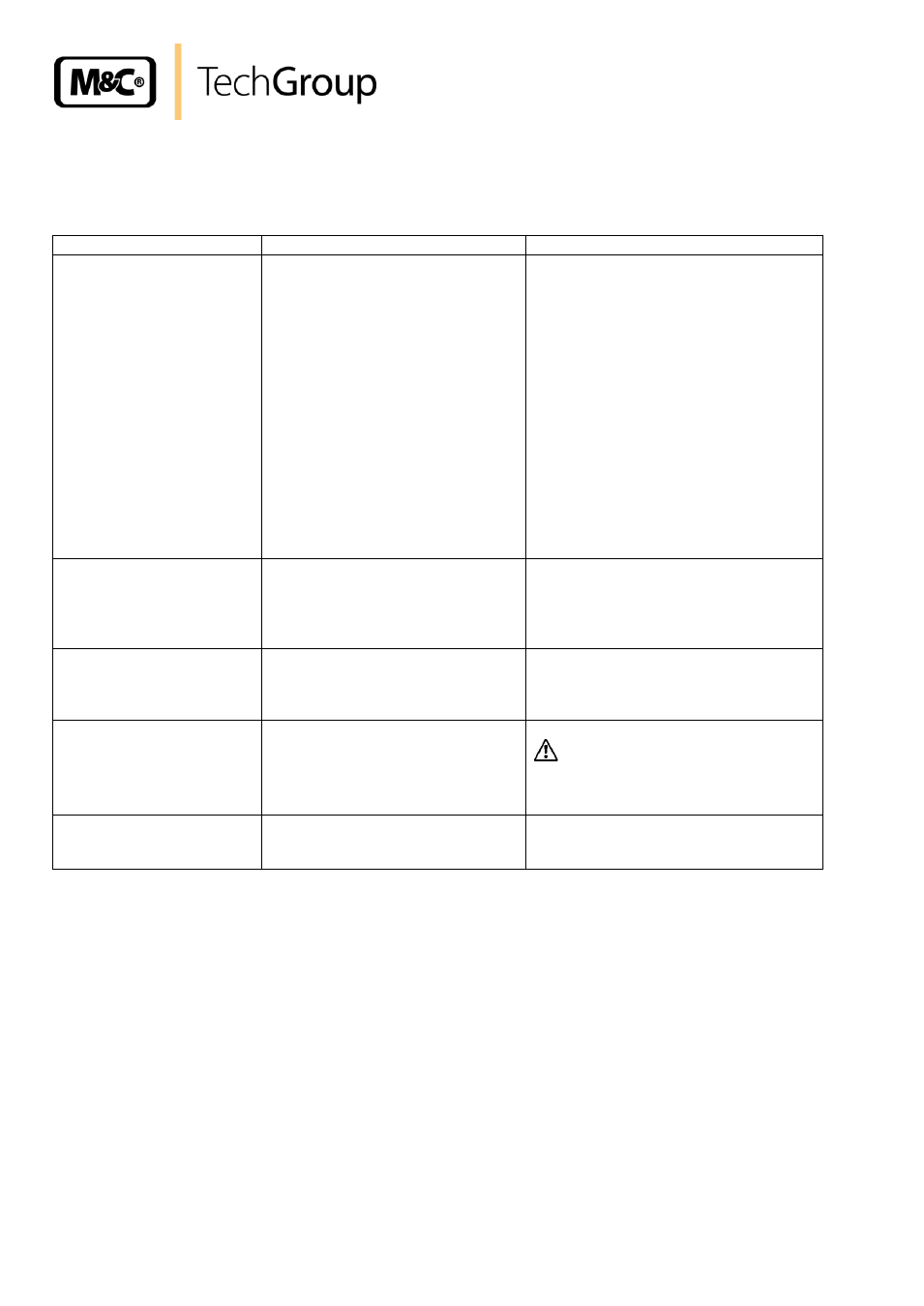

TROUBLE SHOOTING

The following table should give an overview of possible errors and an instruction to check and to

repair them (is not valid for the starting-up period of cooler).

Error

Possible reason

Check/Repair

Condensate in the gas outlet Ambient temperature < 5

C

Cooler overloaded

Peristaltic pump doesn’t work

Tube of the peristaltic pump

defective

Cooling capacity too low

(cooler is not overloaded)

Motor protection switch released

Heat up the components downstream;

eheizen; Keep the operational data (10.);

Change peristaltic pump;

Change the tubing (18.3);

Clean the fins of the condenser (18.2);

Check the vent;

Check the safety distance to other

heated components;

Secure sufficient ventilation;

Thermal load caused by the sample gas

resp. ambient is too high;

Clean the fins of the condenser;

Keep the operational data (10.);

Let the cooler cool down before restarting

it;

Gas flow blocks up reading

Contamination of the sample gas

way

Optimize the dust pre-separation

upstream the cooler;

Clean the gas ways and the coolin

system;

Wrong temperature

Temperature sensor defective

Temperature controller defective

Circuit of cooling agent leaky

Check the PT100-sensor;

Check the temperature controller;

Send the cooler for repair;

Cooler break-down

Power supply interrupted

Check the power supply and reconnect;

Pay attention to the relevant

safety instructions!

Compressor does not work

Compressor defective;

Motor protection switch defective

Send the cooler for repair;