Installation instructions, Supply connections, Hose connections – M&C TechGroup ECM-ExII Operator's manual User Manual

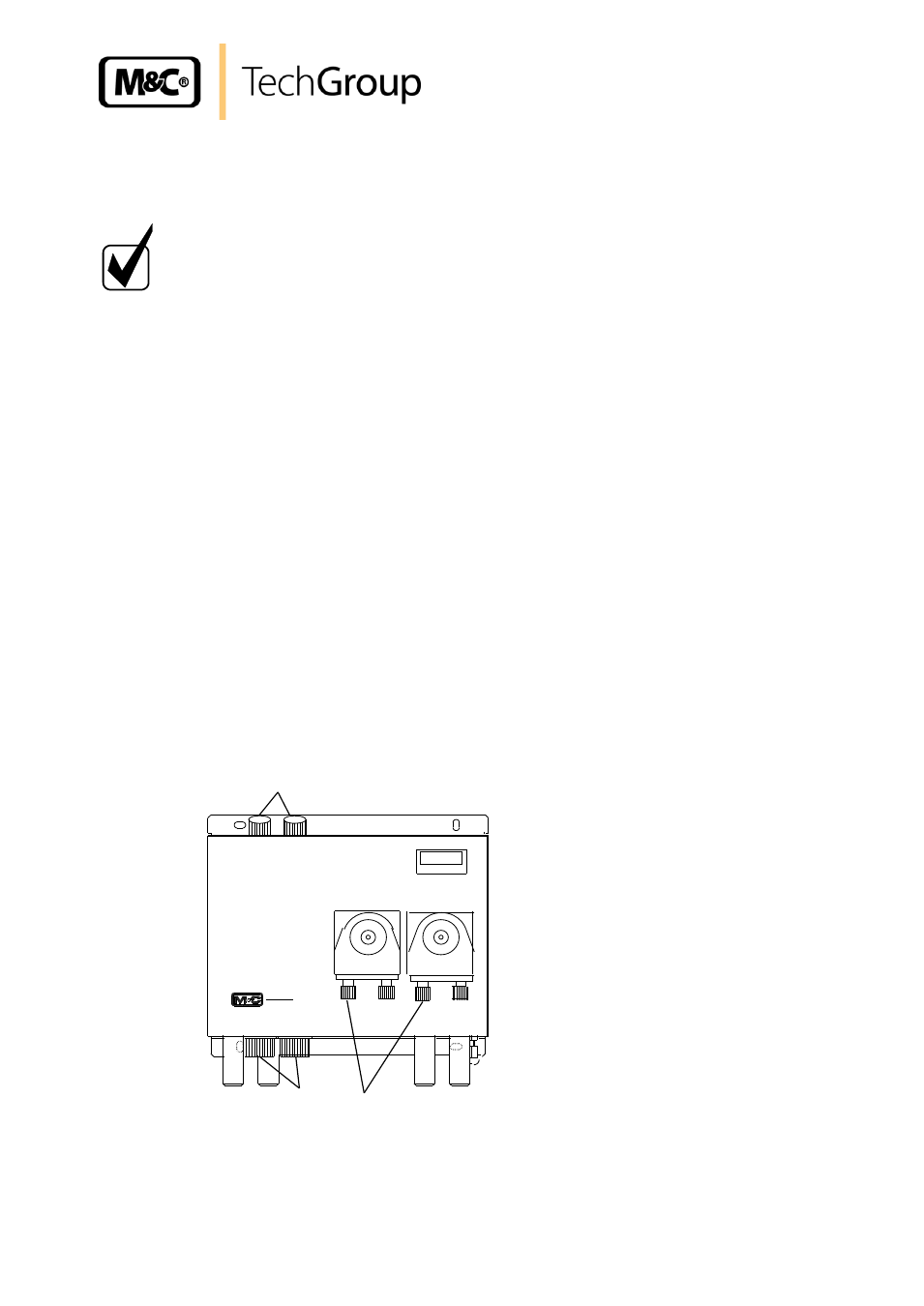

Page 13: Figure 4, Position of the gas and condensate, 14 installation instructions

13

Gas sampling and gas conditioning technology

3-3.0EX-ME

14

INSTALLATION INSTRUCTIONS

The ECM-ExII cooler is suitable for wall mounting.

N O T E !

The cooler is only suitable for dry and clean rooms (IP20). The operating

position for this cooler is exclusively vertical. This is the only way to

ensure proper separation and removal of condensate in the heat

exchangers. During transport and installation, the cooler must always be

stood up with the transport feet positioned underneath so that the oil in

the closed compressor circuit cannot run out of the compressor case.

The cooler should be kept away from sources of heat and well ventilated

when installed, so that condensation from warmth will not occur and

interfere with operation.

The minimum installation dimensions (fig. 2) must be followed without

fail. If the unit is installed in the open, the cooler must be installed in a

housing that is frost-free in winter and adequately ventilated in summer.

Avoid locating the unit in direct sunlight.

Unheated gas sample lines must be provided with slope up to the cooler.

In that case pre-separation of the condensate is not required. Connect the

heated sample line with sufficient thermal decoupling of min. 20cm to the

cooler!

15

SUPPLY CONNECTIONS

15.1

HOSE CONNECTIONS

The connection for sample gas inlet and outlet happens on the upper part of the heat exchangers. For

possible connectors see technical data (10.).

1

EC

M

Cooler

2

1 Gas inlet and outlet

2 Condensate outlet

3 Condensate outlet with optional

mounted peristaltic pump

3

Figure 4 Position of the gas and condensate

Correspondingly tube and hose connectors are optional available by M&C (see document 3-5.1.1).