Aufbau, Basic equipment of the heated protective housings, Figure 2 – M&C TechGroup PAS-500 Operator's manual User Manual

Page 10: Design of the protective housing

10

Gas sampling and gas conditioning technology

10-5.1-ME

13

AUFBAU

The devices PAS100 - 300 have natural ventilation.

In series PAS400

– 500 air circulation is provided by a fan on the back wall of the chamber.

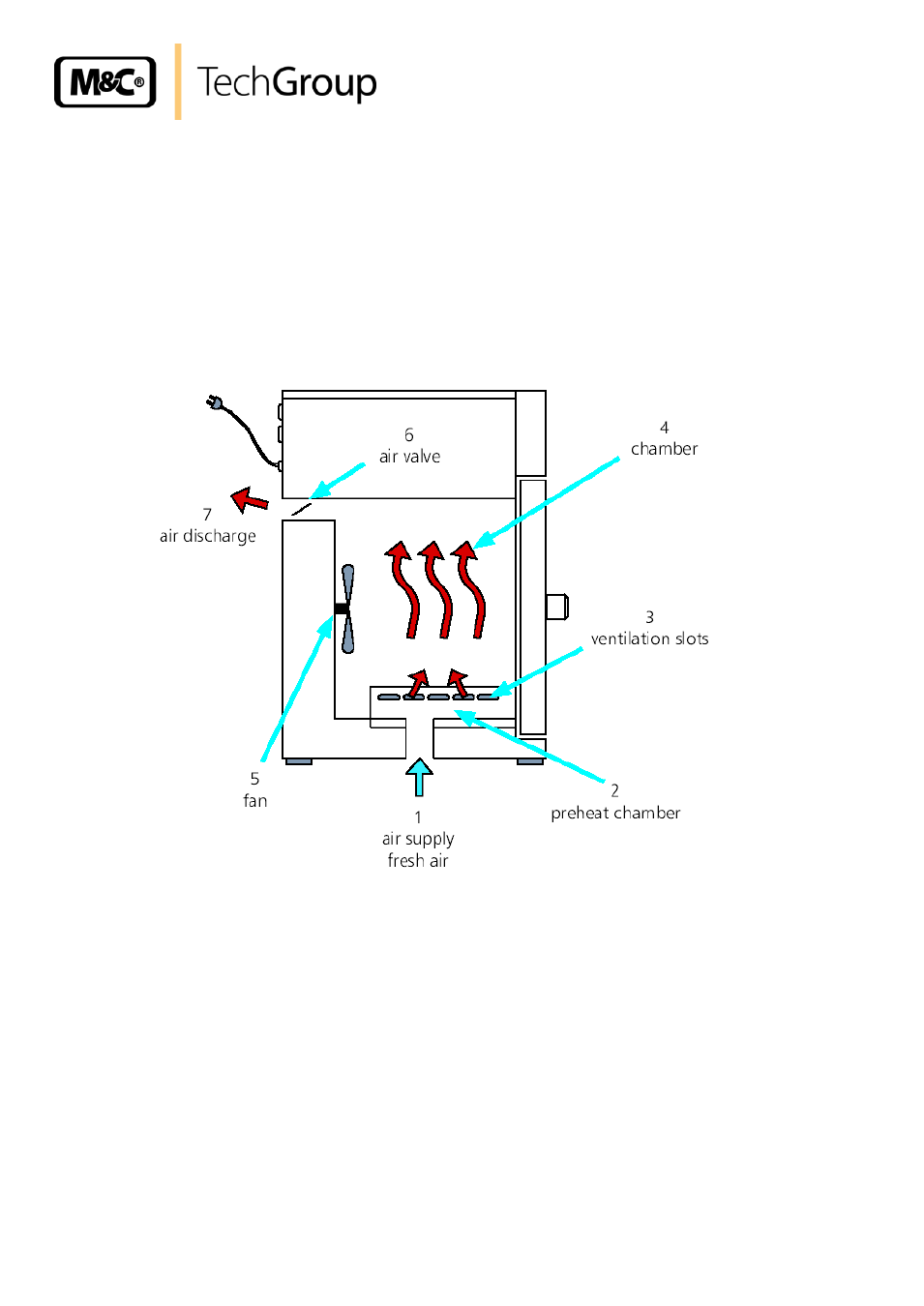

The incoming air (1) is warmed in a preheat chamber (2) in both convection and fan-circulation ovens.

The preheated air enters the chamber (4) through ventilation slots (3) in the chamber side wall. The

fan (5) on the chamber back wall produces a large air throughput and a more intensive horizontal

forced circulation compared with natural convection. The air valve (6) on the back of the oven controls

the rate of air intake and discharge (air change) (7).

Figure 2 Design of the protective housing

13.1 BASIC EQUIPMENT OF THE HEATED PROTECTIVE HOUSINGS

Electronic PID controller with permanent power matching, auto-diagnostic system for rapid fault

finding (see

chapter 15 “Error messages“)

Manually adjustable air valve for re-circulation or fresh air operation

Programmable electronic switch-off timer up to 99 h 59 min

Recessing push/turn control for simple operation of oven

Visual alarm indication

Monitor relay to switch off heating in case of fault

Mechanical temperature limiter (TB Class 1)

High-grade PT100 temperature sensor Class A in 4-wire circuit

Wall bracket