Introduction, Technical data, Application – M&C TechGroup SP10 Operator's manual User Manual

Page 7

7

Gas sampling and gas conditioning technology

2-0.1.1-ME

6

INTRODUCTION

M&C gas sample probes provide direct insitu ultra-fine filtration during continuous gas sampling for

analytic measurements. In this way, part of the necessary maintenance work for a system is concen-

trated on a single point. This filter technology has the major advantage that dust mixtures consisting of

ultra-fine and coarse dusts can be optimally retained with the least possible maintenance work.

Optimal adaptation of the M&C gas sample probe to processing conditions and to measurement work

is a necessary condition for a measurement system to work smoothly. Basically, the gas sample

should be kept to a necessary minimum. This is made possible thanks to optimised downstream gas

processing using M&C components. Only in this way it is possible to reduce maintenance to a mini-

mum while ensuring maximum availability.

7

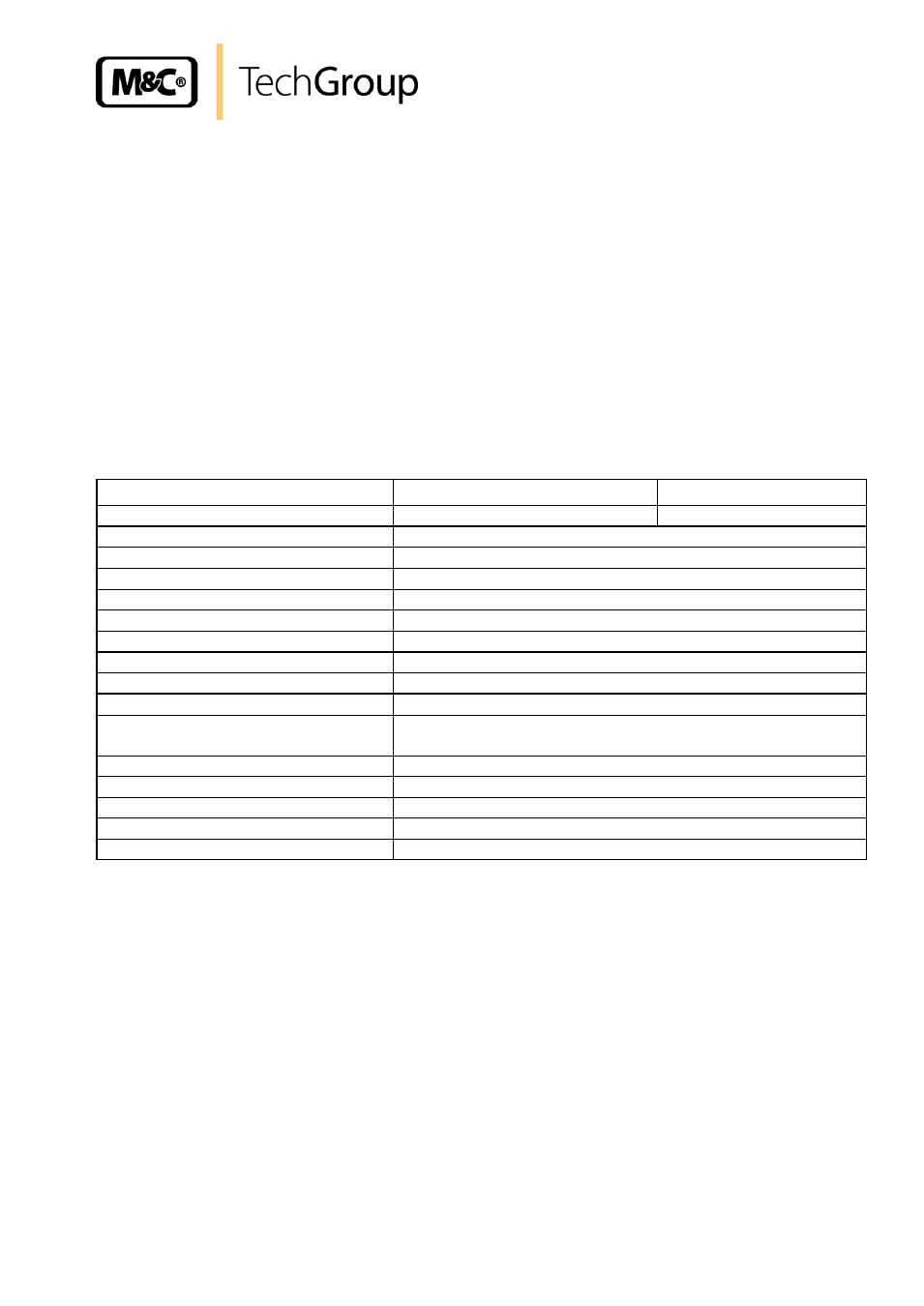

TECHNICAL DATA

Series SP

®

Version SP10

Version SP10-H

Part No.

01 S 1000

01 S 2000

System of protection

IP54

EN60529

Sample temperature

V10 max.600°C * optional HC max. 900 °C

Sample pressure

0,4 bis 6 bar

abs.*

Ambient temperature

-20°C bis +60°C

Dust load

max. 10 g/m

3

*, optional higher 10 g/m

3

Insitu probe length

270 mm*

Heater temperature adjustable

+100 bis +200°C, optional with PT100 without controller

Ready for operation

after 1 h

Sample gas outlet connection

1/8"-NPT internal for tube connectors max.

10mm

Power supply

230V/50Hz / 240V/60Hz 315W, optional

115V/60Hz 300W

Electrical connection

terminals max 4mm

2

, 1x PG13,5 cable gland

Electrical equipment standard

EN60529/61010, EN 60519-1

Mounting flange

DN65 PN6, Form B , rostfr. Stahl 1.4571

Material of sample connecting parts

SS316, SS316Ti, Novapress*

Weight

4 kg

* Standard

**

In case of higher ambient temperatures use option PT100 (Part No. 20S9025) or thermocouple Fe-CuNi respectively Ni-CrNi (Part No.

20S9027 resp. 20S9028) instead of the thermostat controller. Then, an additional electronic temperature controller (see data sheet 2-5.1) is

necessary.

8

APPLICATION