Control jumpers – Siemens MICROMASTER 411 User Manual

Page 48

3 Commissioning

Issue 03/01

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

48

6SE6400-5CA00-0BP0

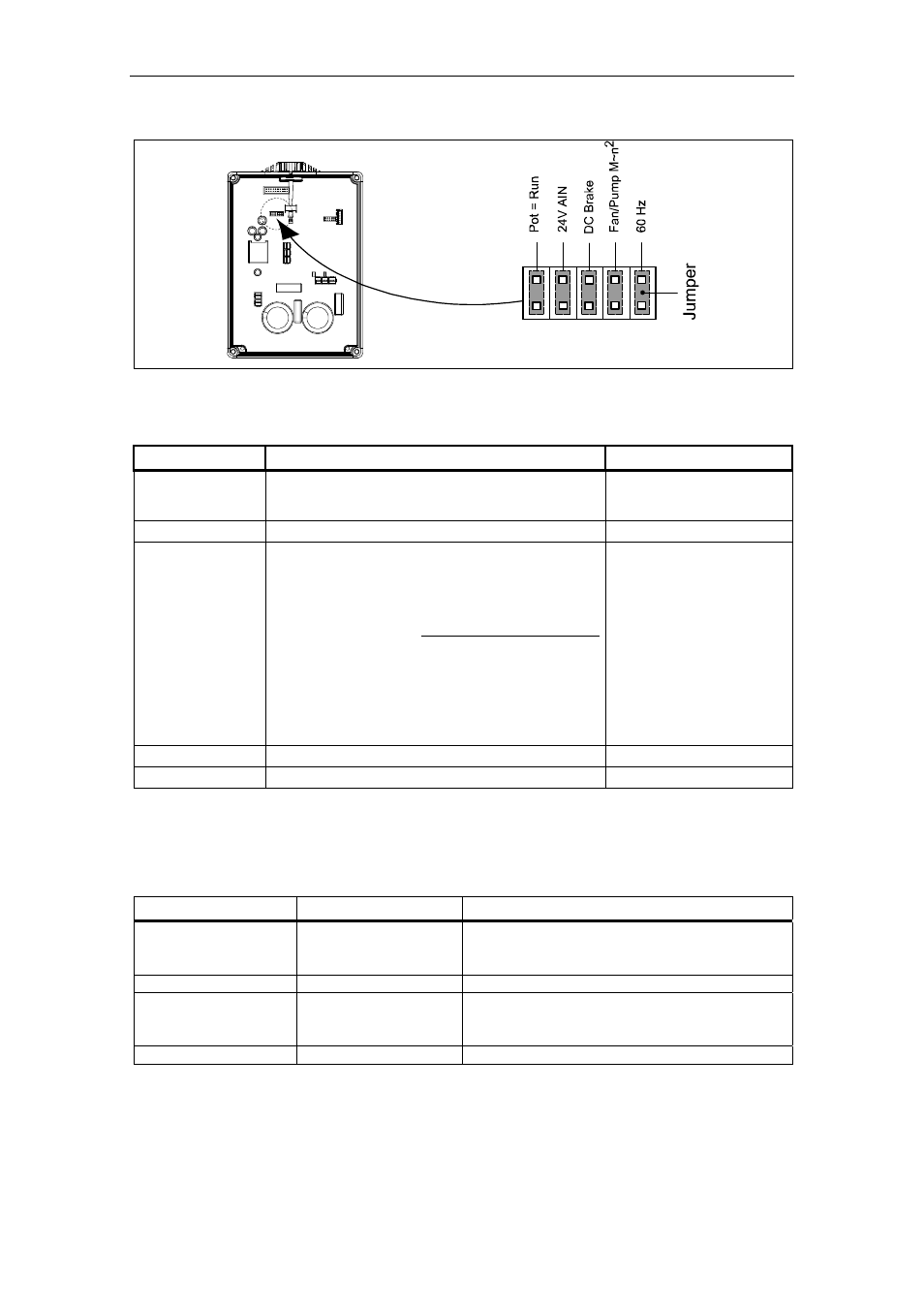

Figure 3-4

Control Circuit Jumpers

Table 3-3

Control Circuit Jumper Settings

Jumper

Jumper Fitted

Jumper Removed

Pot = Run

P0700 = 2

P0705 = 1 (motor potentiometer)

P1210 = 6 automatic restart

P0700 = 2

P0701 = 1

P1210 = 1

24 AIN

No software effect

No software effect

DC Brake

Uses the jumper settings for the ramp settings by the

duration of the direct current braking, to be calculated as

follows.

Duration of direct current braking =

If the drive is quicker to come to a standstill because of the

load conditions, the direct current braking still remains

active fo the calculated time time.

Otherwise the value is held in P1233 (duration of the diret

current braking)

P1233 = 0

Fan/Pump: M~n2

P1300 = 2 (fan curve/quadratic vf)

P1300 = 0 (linear vf)

50/60 Hz

Rated Motor Frequency = 60 Hz

Rated Motor Frequency = 50 Hz

Control Jumpers

In Table 3-4 the behaviour of the Control Jumpers are explained.

Table 3-4

Control Circuit Jumper Behaviour

Status before action(s) Action(s)

Reaction(s) of the inverter

Jumper not fitted

Power down

Fit jumper(s)

Power up

Parameters influenced by jumper will have jumper default

values

Jumper fitted

Cycle power

Parameters influenced by jumper are not changed

Jumper fitted

Power down

Remove jumper

Power up

Parameters influenced by jumper will have “jumper

removed“ default values (normally factory default)

Jumper not fitted

Cycle power

Parameters influenced by jumper are not changed

P0305 (nominal motor current)

r0207 (nominal inverter current)

P1121 (deceleration time) *