Siemens MICROMASTER 411 User Manual

Page 125

Issue 03/01

10 Engineering Information

MICROMASTER 411 & COMBIMASTER 411 Operating Instructions

6SE6400-5CA00-0BP0

125

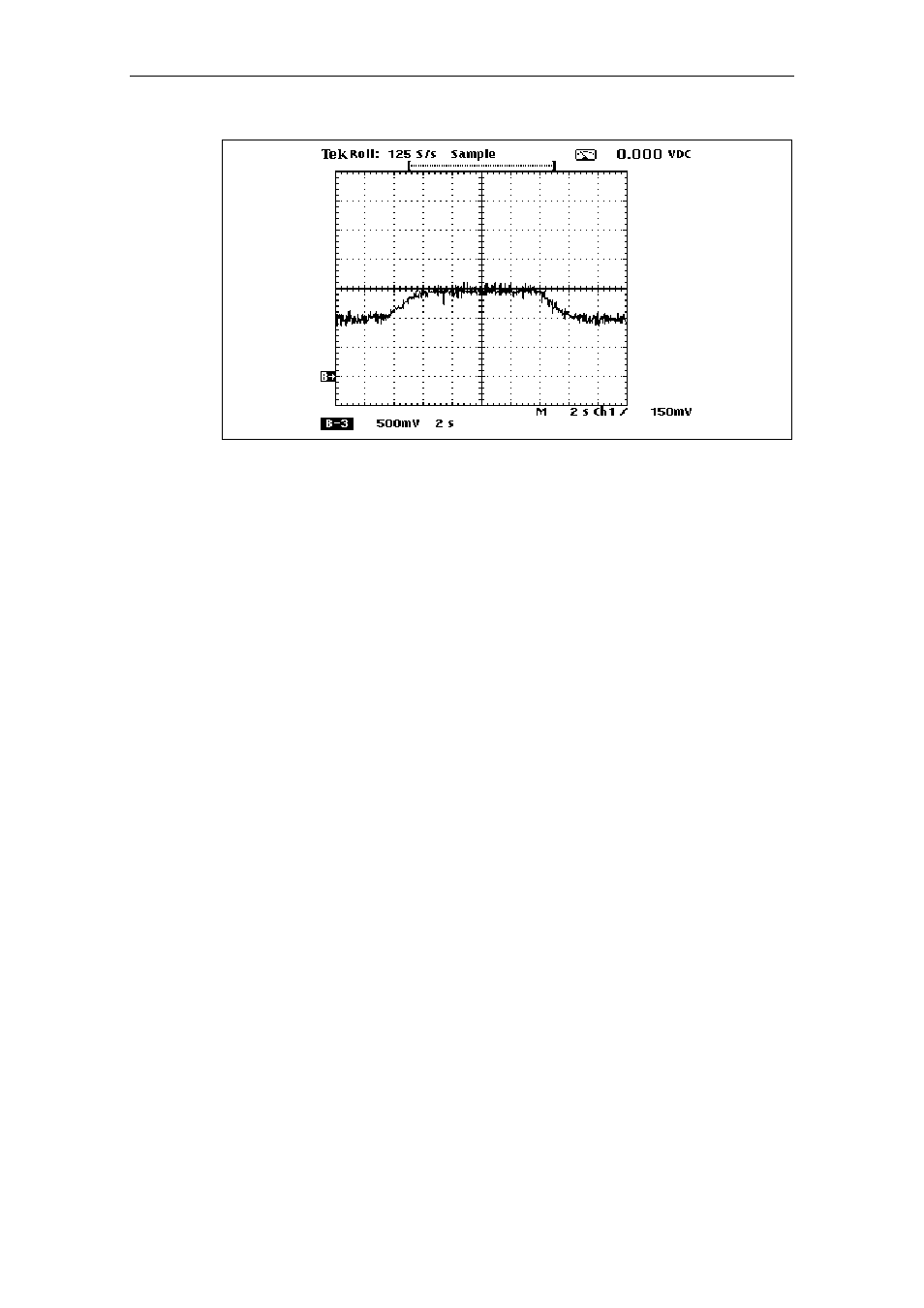

Figure 10-6 Damped response: P2280 = 0.20; P2285 = 0.15 s

Values of P2280 and P2285 are determined by the relationship between motor

frequency and the PI control quantity (e.g. pressure).

When optimizing a control process an oscilloscope is recommended to monitor the

feedback signal to see the system response. Most commonly small PI setpoint step

changes (1- 10%) without the PI ramp times (P2257 = P2258 = 0.0 s) are used to

evaluate the system response. Once the desired response profile has been

achieved, the operational ramp times are then set.

It is recommended to start with a small P term (e.g. P2280 = 0.20) and adjust the I

term until stable operation constant is achieved. A small PI setpoint change should

then be given and depending on the system response the parameters adjusted

according to the tendencies shown in the figures above.

In general, the most stable control is achieved by using both proportional and

integral terms, and if the system is liable to experience sudden disturbances we

would not recommend setting the P term (P2280) greater than 0.50.

A block diagram showing the relationships and interaction between PI Setpoint and

PI Feedback is shown in Figure 10-10 on page 128.