Wireless remote controller – Sanyo DHX4852 User Manual

Page 59

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

3-11

Control of W-2WAY ECO-i SYSTEM

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

CN1

(optional)

(optional)

1 2

1 2

Indoor

unit

(sub)

(main)

Receiver unit

Remote controller

terminal board

Ground

Wireless remote

controller kit

Wired remote

controller

Remote control wiring (field supply)

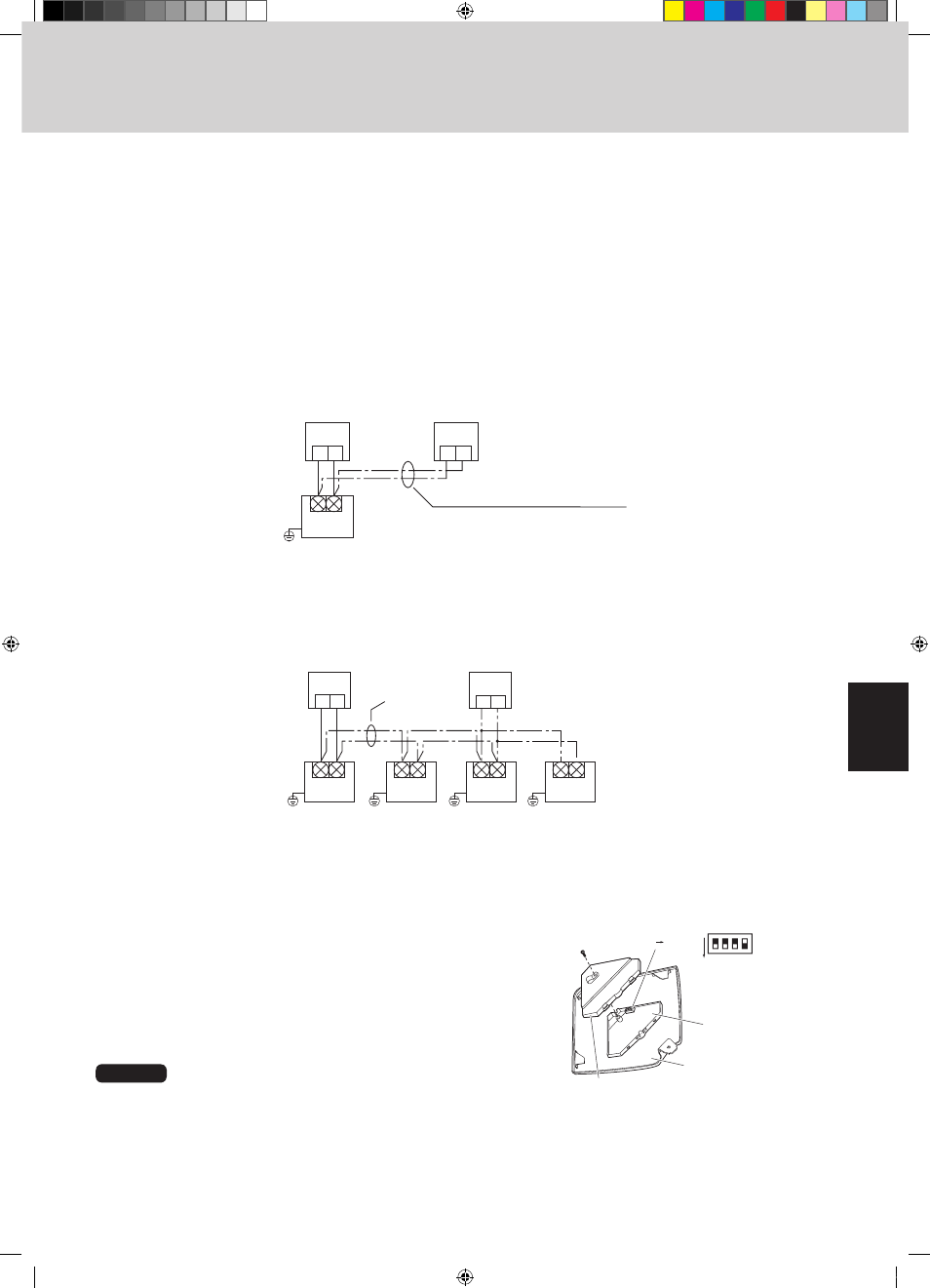

When 1 indoor unit is operated with 2 remote controllers:

(The indoor unit runs according to which of the remote controllers is assigned as the main or sub unit.)

*

*

* Use field wiring cables with a

cross-sectional area of at least

0.5mm

2

to 2mm

2

.

* The maximum total length of

crossover cables must be no

longer than 400m.

CN1

(optional)

1 2

1 2

(optional)

Indoor

unit No.1

Indoor

unit No.2

Indoor

unit No.3

Indoor

unit No.4

Receiver

unit

(Main)

(Sub)

Remote controller

terminal board

When several groups of indoor units are operated with 2 remote controllers:

(The remote controller (main or sub unit) can operate with any indoor unit.)

Wireless remote

controller kit

Wired remote

controller

Remote control

wiring among the

control groups

(field supply)

* Use field wiring cables with a

cross-sectional area of at least

0.5mm

2

to 2mm

2

.

* The maximum total length of

crossover cables must be no

longer than 200m.

*

*

Ground

Ground

Ground

Ground

Fig. 3-6

Fig. 3-5

Receiver PCB

Receiver unit

cover

ON

1

2

3

4

Adjustable

corner cap

S003

Bit 1: OFF ON

2. Wireless Remote Controller

(1) To assign the wired remote controller as the sub unit,

locate the address connector at the rear of the wired

remote controller PCB and disconnect it. Reconnect it to

the sub unit position.

(2) To assign the wireless remote controller as the sub unit,

locate the dip switch [S003] on the wireless receiver unit

PCB. Set the No. 3 switch to the ON position.

2-5. How to use the Test Run Setting

1. Set DIP switch [S003] No. 1 on the wireless receiver unit

PCB from OFF to ON.

2. All indicator lamps in the display section blink during test

run operation.

3. No temperature control is available during the test run.

4. After the test run, be sure to reset DIP switch No. 1 back

to the OFF position and check that no indicator lamps

are blinking. Then remount and attach the PCB cover as

before.

To avoid placing excessive operating load on the equipment,

use this function only when conducting the test run.

NOTE

AWG#20 to AWG#14

longer than 1320 ft.

AWG#20 to AWG#14

longer than 660 ft.

TD831138-02_W-2WAY.indb 11

2007/07/26 14:31:18