Ubrication of, Echanical, Omponents – Servis-Rhino RHINO AGM72 User Manual

Page 160: Maintenance, Lubrication of mechanical components

MAINTENANCE

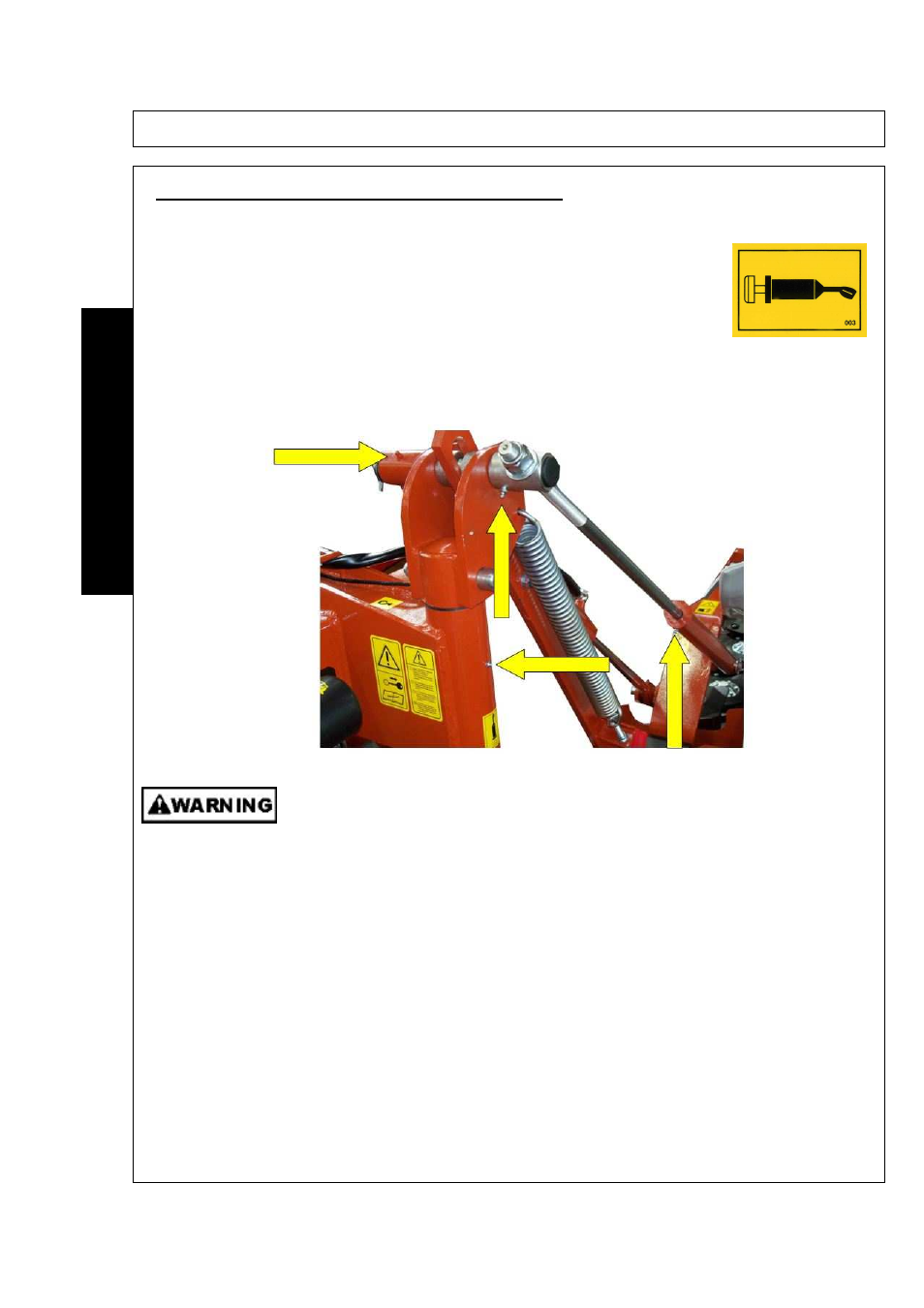

Lubrication of Mechanical Components

Before operation and every 8 hours of work,

lubricate

all bearings, pins and the telescopic rod of the PTO joint

using quality grease.

When the mower is not used for a longer period, clean and grease the drive shaft.

In winter and when temperature is very low grease pipes to protect plastics.

Clean debris from the lubricators heads before injecting lubricating grease.

Grease following point with lithium grease:

M

A

IN

T

EN

A

N

C

E

All models have 4 points to be greased:

Before performing an inspection, stop the engine of the tractor, remove the ignition key and

disengage PTO-shaft transmission.

Collect used oil and bring it to the Oil Collection Centre. Do not pollute the environment.

Lubrication of the cutter bar

Change oil in the bar

after the first 10/15 hours of work

.

Then replace oil

every 200 hours of work

and at least once a year. When the mower is used for a long period, check

oil level on a daily basis and add oil if necessary.

To check oil level in the cutter bar let it set in vertical position for 5 minutes to allow time for oil to flow to the bottom of

the bar.

Lock the cutter bar in the vertical position using the hydraulic locking device.

AGM 52-62-72-82

10/10

Maintenance Section 5-4

© 2010 Alamo Group Inc.