Thread settings, Changing gears for feed/threads, Notice – Grizzly G0554 User Manual

Page 40

-38-

G0554 Gear-Head Floor Lathe

Thread Settings

The Model G0554 lathe is capable of cutting inch

and metric threads. Most inch threads can be

cut without changing gears. Metric threads and

a few inch threads require that you change the

gears. This will be explained in the next sub-sec-

tion. Below are instructions for setting levers and

changing gears for threading.

To determine thread settings:

1. Determine the threads per inch (TPI) for inch

threads or pitch for metric threads.

2. Examine the appropriate thread chart. For

inch threads and metric threads (see

Figure

55) or examine chart on the front of the head-

stock (see

Figure 56).

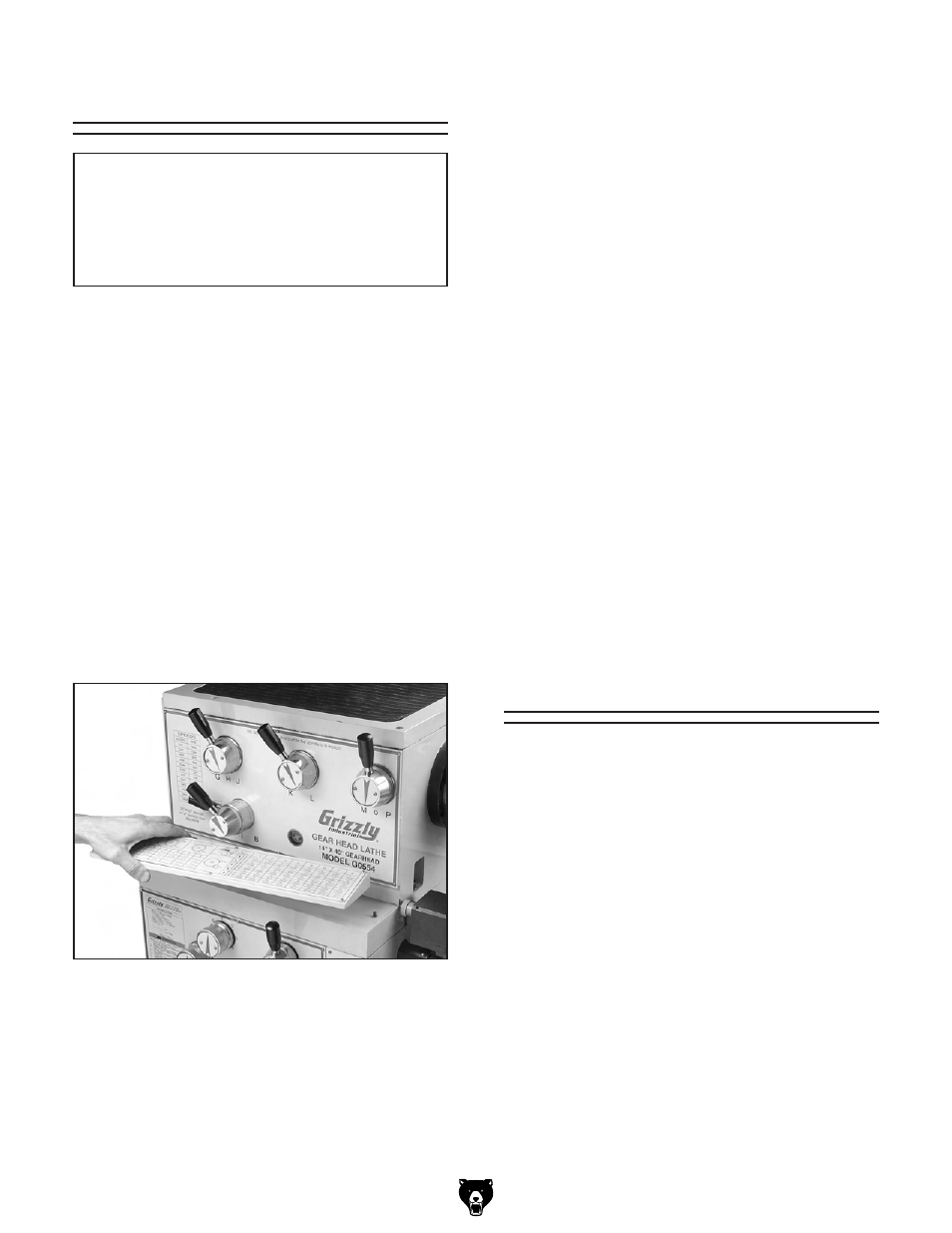

Figure 56. Headstock thread chart.

3. Find the corresponding thread info from the

chart and work to the left and up to determine

the correct lever settings.

Example: To cut 20 TPI thread, the handle

combination would be "B, C and 3".

4. Move the feed rod lock knob to the open posi-

tion (see

Figure 53).

5. Move the selectors to the appropriate letter/

number setting by rotating the handle left or

right.

6. Move the feed direction selector to the desired

direction for movement (see

Figure 51).

7. Move the feed rod lock knob to the locked

position.

Note: The spindle must be OFF to make

changes that affect the gear box. You may

also need to rotate the spindle by hand or

move the apron right/left to get gears to

engage properly.

Changing Gears for

Feed/Threads

The Model G0554 lathe comes with the 25T,

127T, & 50T gears installed. This set of gears will

cover most feeds and inch threads. The 30T, 32T,

and two 40T gears are provided so that additional

feeds and inch/metric threads may be cut.

To change the gears:

1. UNPLUG THE LATHE!

2. Open the end cover door to expose the head-

stock gears.

3. Loosen the hex nut on the pivot just below

the large gear in

Figure 57, Item A.

NOTICE

Some threading operations may damage

the lead screw if performed at high speeds.

Always use the slowest speed possible for

your particular operation!