Manual feed, Setting rpm – Grizzly G0554 User Manual

Page 36

-34-

G0554 Gear-Head Floor Lathe

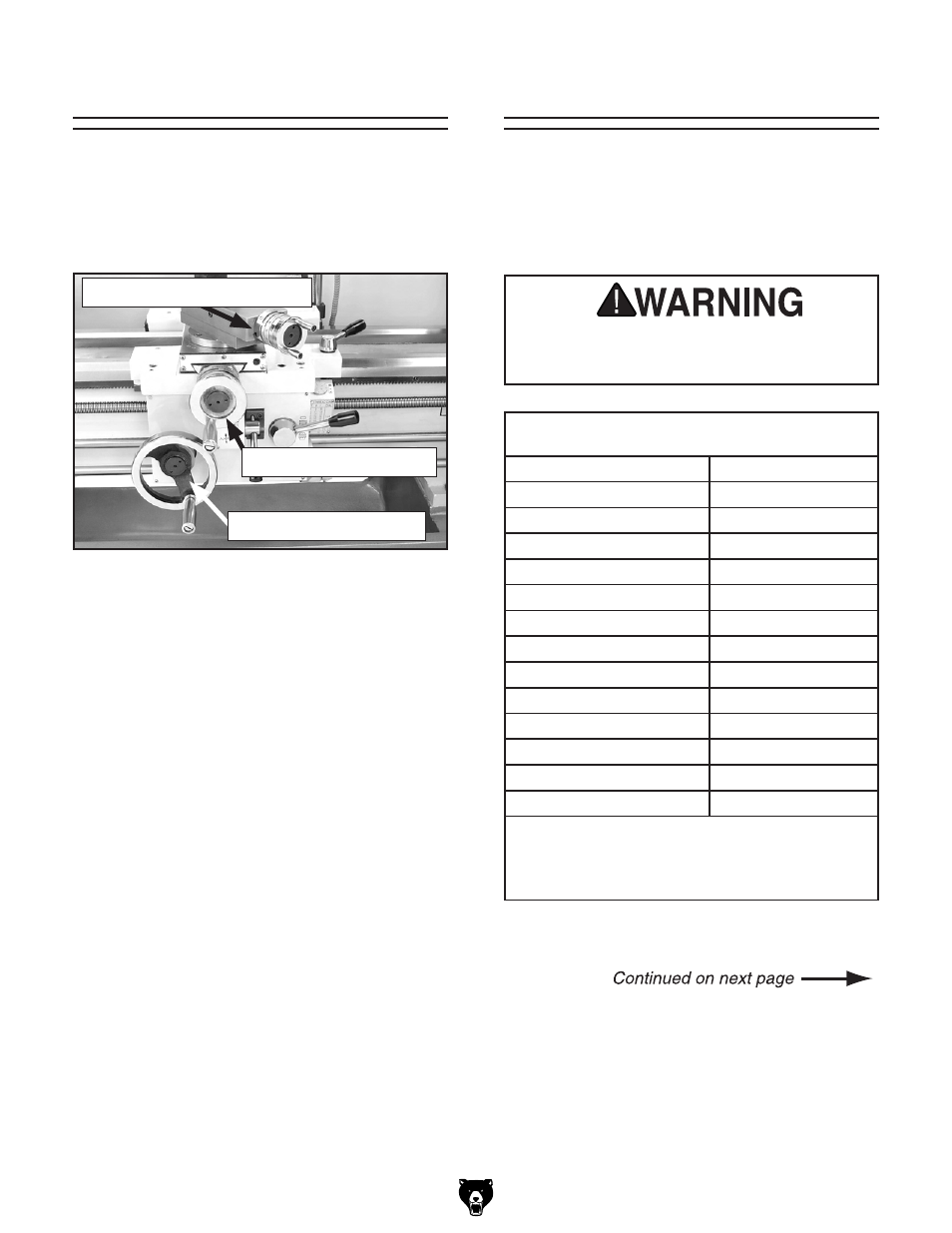

Manual Feed

You can manually move the cutting tool around

the lathe by three methods. This section will

review the individual controls on the carriage and

provide descriptions of their uses (see

Figure

47).

Figure 47. Carriage Controls.

Cross Feed Handwheel

Longitudinal Handwheel

Compound Slide Handwheel

Longitudinal Handwheel

The longitudinal handwheel moves the carriage

left or right along the bed. This control is help-

ful when setting up the machine for turning or

when manual movement is desired during turning

operations.

Cross Feed Handwheel

The cross slide handwheel moves the top slide

toward and away from the work. Turning the dial

clockwise moves the slide toward the workpiece.

The graduated dial can be adjusted by holding the

handwheel with one hand and turning the dial with

the other.

Compound Slide Handwheel

The compound slide handwheel controls the posi-

tion of the cutting tool relative to the workpiece.

The compound slide is adjustable for any angle

within its range. The graduated dial is adjust-

able using the same method as the dial on the

cross slide. Angle adjustment is controlled by cap

screws on the base of the compound slide.

Setting RPM

To determine the needed RPM:

1. Use the table in Figure 48 to determine the

cutting speed required for the material of

your workpiece.

Cutting Speeds for High Speed Steel (HSS)

Cutting Tools

Workpiece Material

Cutting Speed (sfm)

Aluminum & Alloys

300

Brass & Bronze

150

Copper

100

Cast Iron, Soft

80

Cast Iron, Hard

50

Mild Steel

90

Cast Steel

80

Alloy Steel, hard

40

Tool Steel

50

Stainless Steel

60

Titanium

50

Plastics

300-800

Wood

300-500

Note: For carbide cutting tools, double the cut-

ting speed. These values are a guideline only.

Refer to the MACHINERY'S HANDBOOK for

more detailed information.

Figure 48. Cutting speed table for HSS cutting

tools.

Failure to follow RPM and feed rate guide-

lines may threaten operator safety from

ejected parts or broken tools.