Centers, Notice – Grizzly G0554 User Manual

Page 32

-30-

G0554 Gear-Head Floor Lathe

Centers

The dead center is used in the tailstock to support

workpieces. When used in the tailstock, make

sure to keep the dead center tip and workpiece

lubricated.

The Model G0554 lathe is supplied with two

MT#3 dead centers–one is HSS and one is car-

bide tipped. The supplied MT#5-#3 sleeve fits

into the spindle taper to hold the MT#3 center.

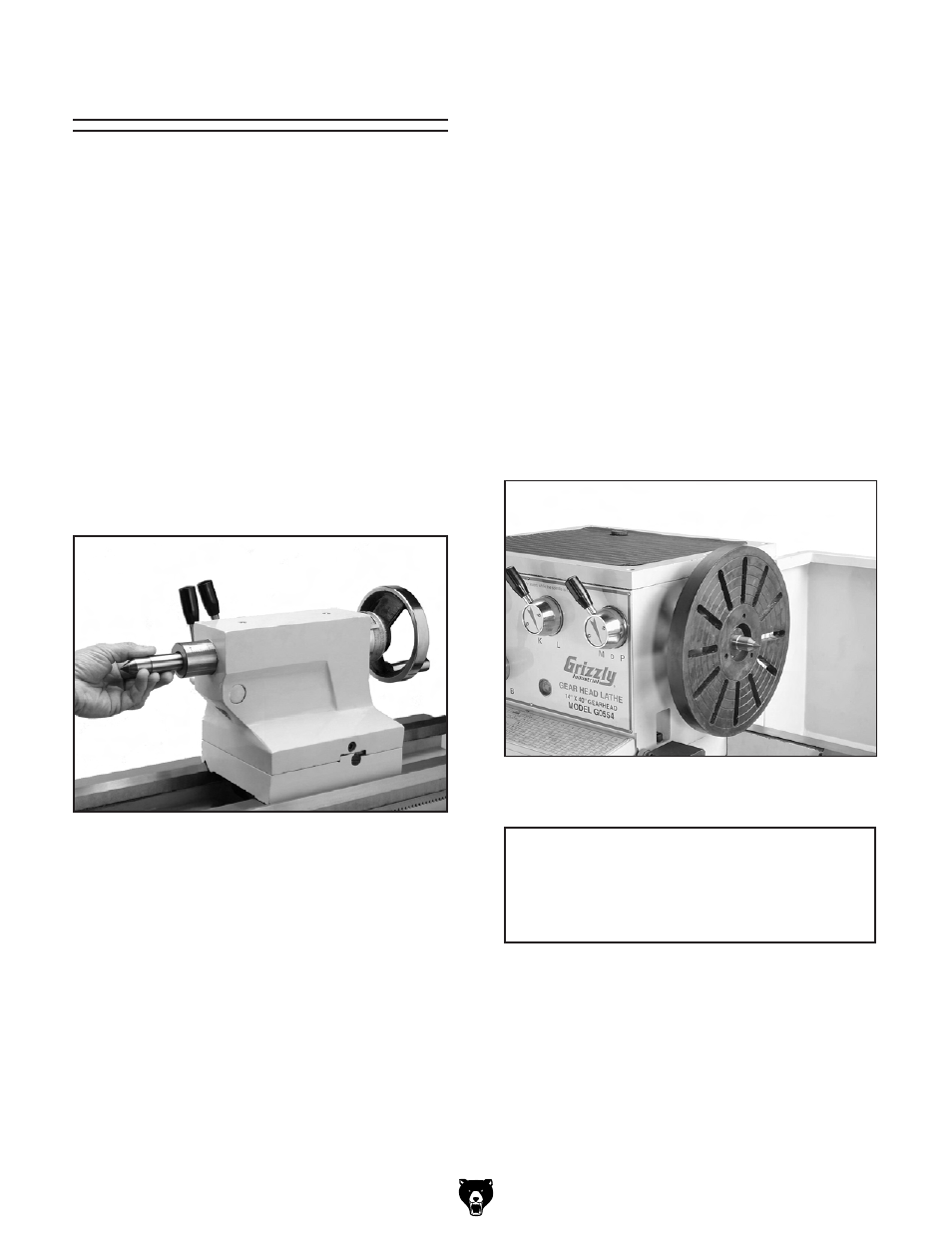

To install a dead or live center:

1. Feed the quill out about 1" so that the dead

center can be inserted.

2. Insert the dead center into the quill opening.

Matching tapers provide the locking action

(see

Figure 39).

Figure 39. Inserting dead center.

Figure 40. Typical faceplate and dead center

setup.

NOTICE

Failure to keep dead center point well

lubricated will damage dead center and

workpiece.

The dead center can also be used in the spindle.

The most common application is when using the

faceplate (see

Figure 40).

To install the dead center in the spindle:

1. Remove the chuck from the spindle.

2. Install the dead center in the spindle sleeve.

3. Install the sleeve and center into the spindle

opening.

4. Attach the faceplate to the spindle.

Note: When using the dead center in the

spindle, use a lathe dog so that your part will

rotate with the spindle and not spin on the

dead center tip.

3. Move the tailstock into position and lock in

place.

4. Feed the quill into the workpiece.

Note: Make sure there is a center drilled hole

in the end of workpiece for the dead center.

5. Lock the quill into place once the live center

and the part rotate together. The quill may

need to be adjusted during operation.

6. To remove the dead center, retract the quill

until the dead center pops free.