Reviewing dtc 525 sequence of operations – FARGO electronic DTC500 User Manual

Page 7

RESTRICTED USE ONLY

Fargo Electronics, Inc.

DTC500 Series Card Printer/Encoders User Guide (Rev. 5.0)

7

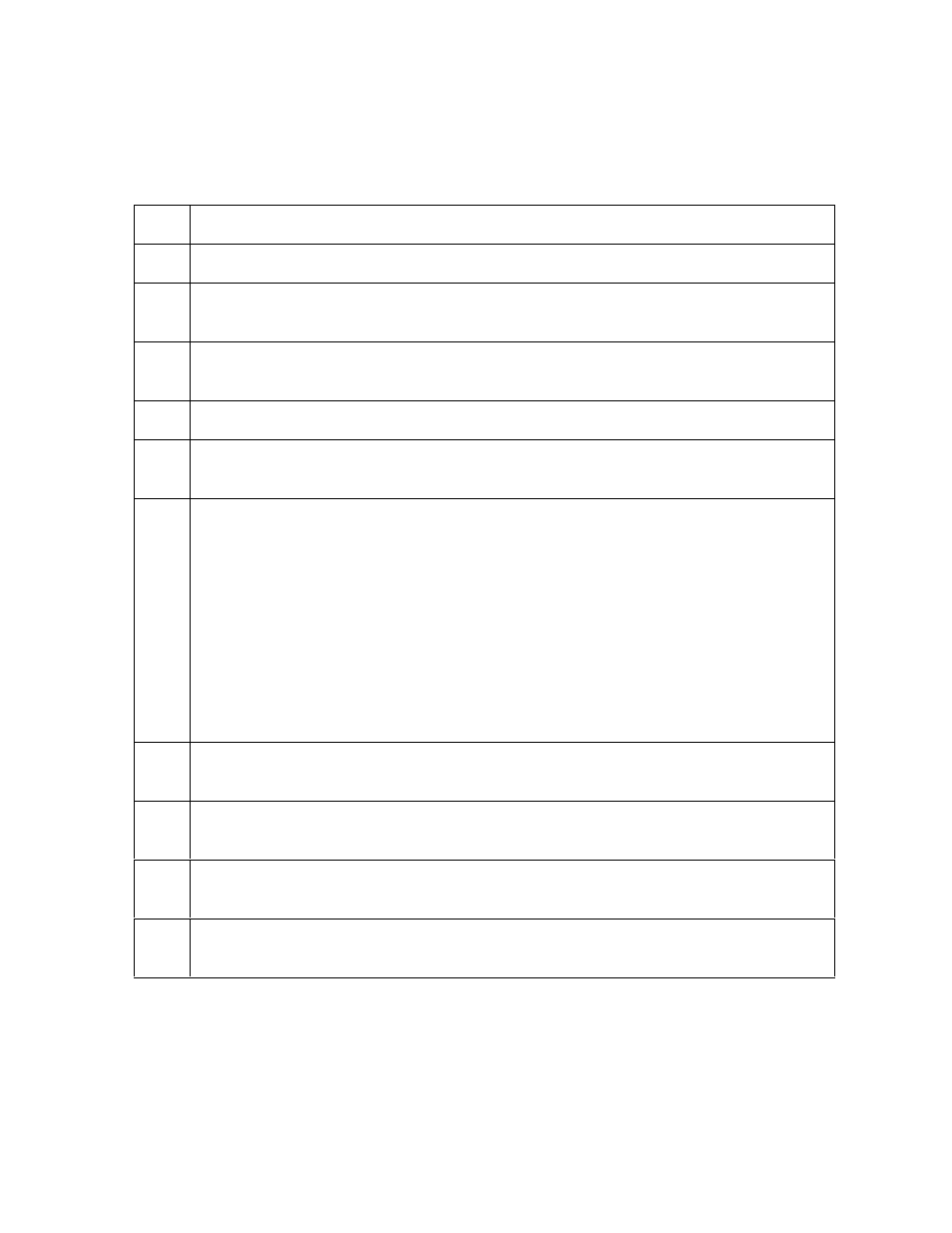

Reviewing DTC 525 Sequence of Operations

The following sequence describes a DTC525 doing a dual sided full color print job with

magnetic encoding.

Step Process

1

The File information is received from the PC.

2

The Flipper Stepper activates and rotates the Flipper Table until the Flipper Home

Sensor is activated.

3

The Flipper Stepper rotates the Flipper Table back a specific number of steps

(based on the Flipper Offset setting) to return the Flipper Table to a level position.

4

The Card Detection Sensor detects the presence of a Card in the exception feed.

5

The Hopper Lift Motor activates and lowers the Card Hopper until the Hopper Lift

Sensor detects a change in state.

6

The Card Detection Sensor detects the presence of a Card.

If no card is seen, the following takes place:

a. The Hopper Lift Motor activates and raises the Card Hopper until the Hopper

Lift Sensor detects a change in state.

b. The Hopper Transport Motor activates and moves to the other Hopper until

the Hopper Position Sensor detects a change in state.

c. The Hopper Lift Motor activates and lowers the card Hopper until the Hopper

Lift Sensor is activated.

d. The Card Detection Sensor detects the presence of a Card.

7

The Card Feed Stepper activates and feeds a card through the Cleaning Roller

and onto the Flipper Table.

8

The Flipper Stepper rotates the Flipper Table a certain number of steps (based on

the Encoder Angle setting) to position the card for Encoding.

9

The Encoder/Flipper Feed Motor activates until the Card passes the Encoding

TOF Sensor.

10

The Encoding Feed Motor feeds the Card back to the Flipper Table while the

Magnetic Encoding Head transfers data onto the Magnetic Stripe.

Continued on the next page