5quality controls – ITC VerifyNow System Platelet Reactivity Test User Manual

Page 21

Page 17

14439.C 03/2013

Quality Controls - 5

VerifyNow System User Manual |

USA

5

Quality Controls

Accumetrics has designed the VerifyNow System with a comprehensive set of quality control measures

that provide control of the complete analytical process as defined in the CLIA regulation. This includes

control of the following factors:

•

Test system performance (both instrument and reagents)

•

Environmental conditions

•

Variations in operator performance

The extensive quality control features of the VerifyNow system are outlined in the Appendix.

Accumetrics’ recommendations for frequency of external control (Electronic Quality Control, Wet Quality

Control levels 1 and 2) testing are stated in the individual tests’ package inserts and are summarized in

Table 5-1.

Electronic Quality Control (EQC) is a procedure during which the software will verify instrument optics

performance, reagent mixing, and instrument pneumatics. Wet Quality Control (WQC) follows the same

procedure as an actual patient test, except that optically absorbent solution is used in lieu of blood. It

verifies continued performance by checking that actual results are within a standard range.

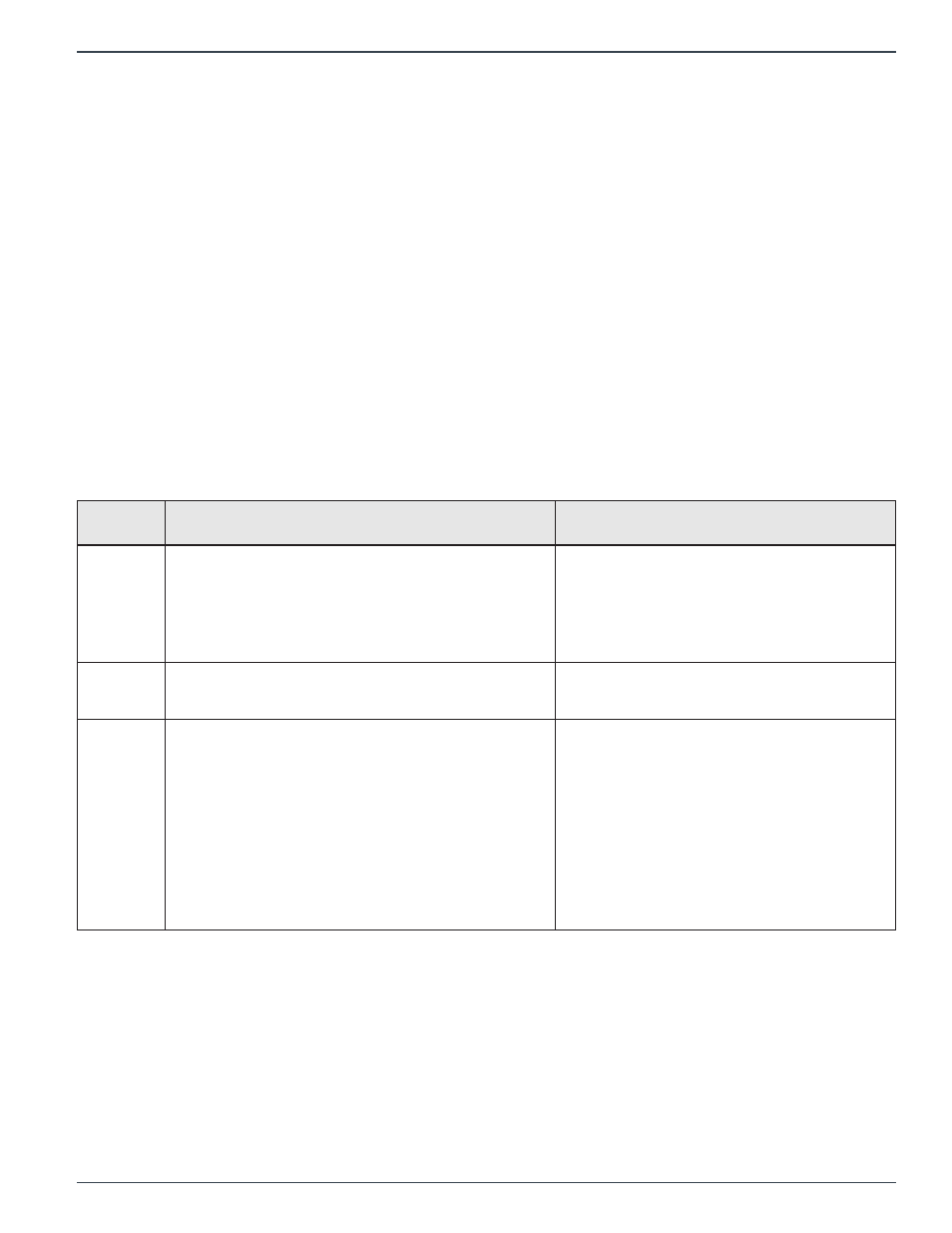

Table 5‑1 Quality Control (QC) Tests

Quality

Control

When do I use it

What it does

Electronic

(EQC)

Recommended to run once a day to confirm the integrity

of the instrument.

Run after resetting the date and time.

Verifies that instrument components are

functioning properly – including optics, reagent

mixing, and pneumatics. It also confirms correct

calibration parameters and simulates testing

at two levels of results to check correct data

acquisition and calculations.

Level 1

WQC

Run during troubleshooting to resolve unexpected events.

Use as part of your institution’s quality control program.

Verifies instrument performance by checking that

actual results are within a lower range of values.

Level 2

WQC

Run before the first use of each new lot (or shipment) of

test device kits.

Run during troubleshooting to resolve unexpected events.

Refer to Chapter 10, Troubleshooting.

Run when the test device kit temperature indicator (if

present) shows exposure to elevated temperatures. Refer

to Chapter 4, Reagent Storage and Handling.

Run every 30 days (for

PRUTest and IIb/IIIa Test).

Use as part of your institution’s quality control program

Verifies instrument performance by checking that

actual results are within a higher range of values.

The following sections provide a detailed description of the procedures.

5.1

Electronic Quality Control

Electronic Quality Control (EQC) is the primary quality control mechanism for the VerifyNow Instrument.

It consists of a re-usable device that is inserted by the operator into the test port and is used to perform

a comprehensive testing routine that confirms performance of key instrument components.

This procedure involves a reusable EQC device and takes up to two minutes. If a fault is detected in any

of its systems, the instrument cannot perform patient testing until the fault is corrected.