Heat Controller Water Source Heat Pump User Manual

Page 120

WattMaster WHP

Section 4

4-38

Start-Up and Troubleshooting

5.4.3

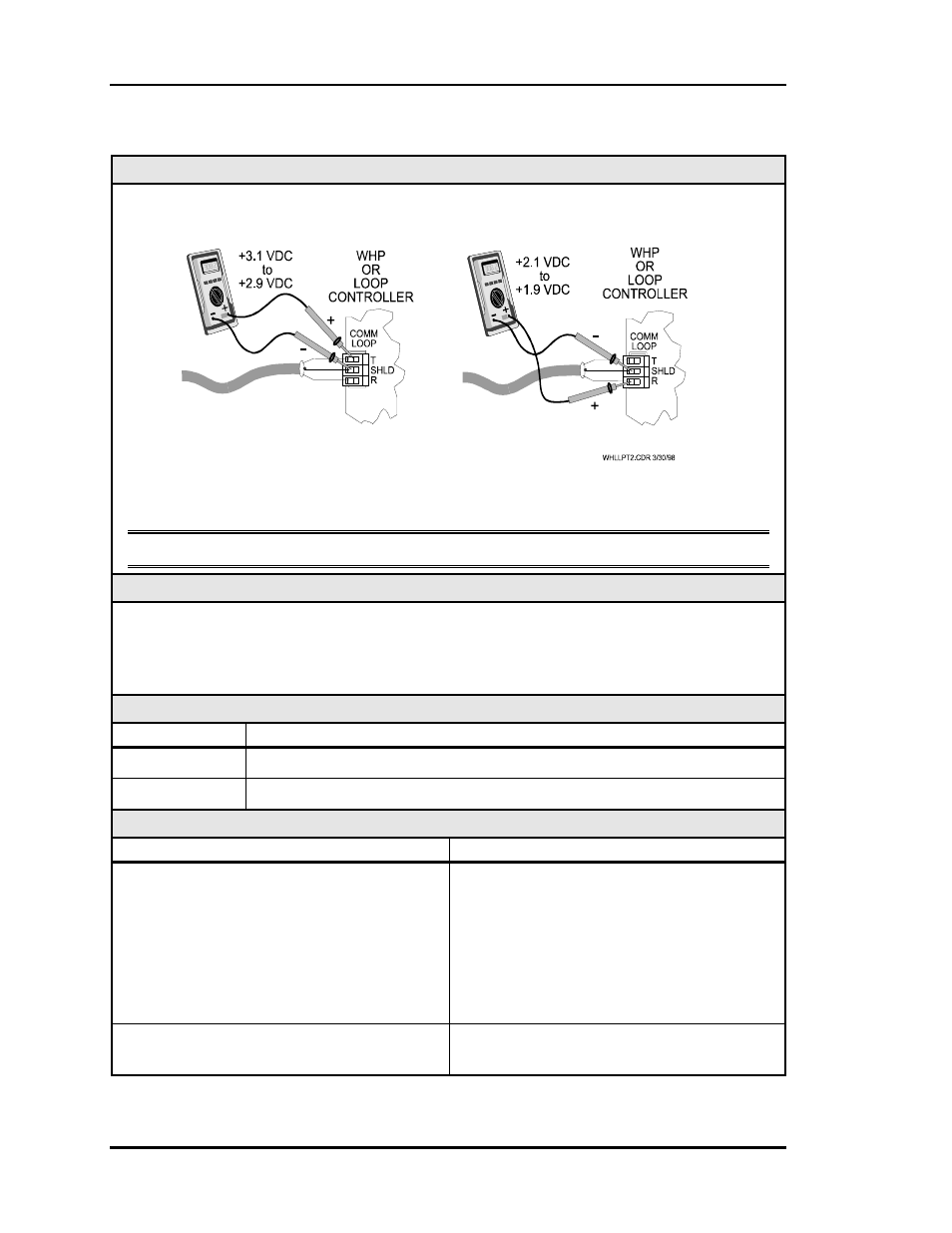

Checking the Local Loop at a WHP Loop Controller

Diagram

Meter Set To Read DC Volts

The indicated readings are typical of a normal operating system. Actual readings may vary

slightly due to the number of units installed and other factors. Any significant deviation

from these values generally indicates a problem.

Note: These tests assume that a MiniLink is connected and powered up.

Overview

Proper loop voltages are essential for reliable communications. It is normal to see fluctua-

tions on an operating communications loop. The average value should be close to the ac-

ceptable range described below. Values will vary upon initial powerup for about 30-45 sec-

onds. The voltages may fluctuate as normal communications occur.

Measurements

Local Loop

Acceptable Range

T – SHLD

2.9 - 3.1 Volts DC

R – SHLD

1.9 - 2.1 Volts DC

Action

Condition

Action

If meter reads between 2.4 VDC and 2.5

VDC

The Comm Loop “floats” at 2.4 - 2.5VDC

when only controllers are connected to the

loop. When a MiniLink is connected it will

“bias” each side of the loop to the values

listed above.

1) No CommLink II or MiniLink is con-

nected and powered up.

2) If a CommLink II or MiniLink is con-

nected, look for “open” wiring.

If voltages are too high or too low on either

side

One or more devices connected to this loop

have damaged Comm Driver chips.