8 checking the minilink local loop driver – Heat Controller Water Source Heat Pump User Manual

Page 114

WattMaster WHP

Section 4

4-32

Start-Up and Troubleshooting

5.3.8

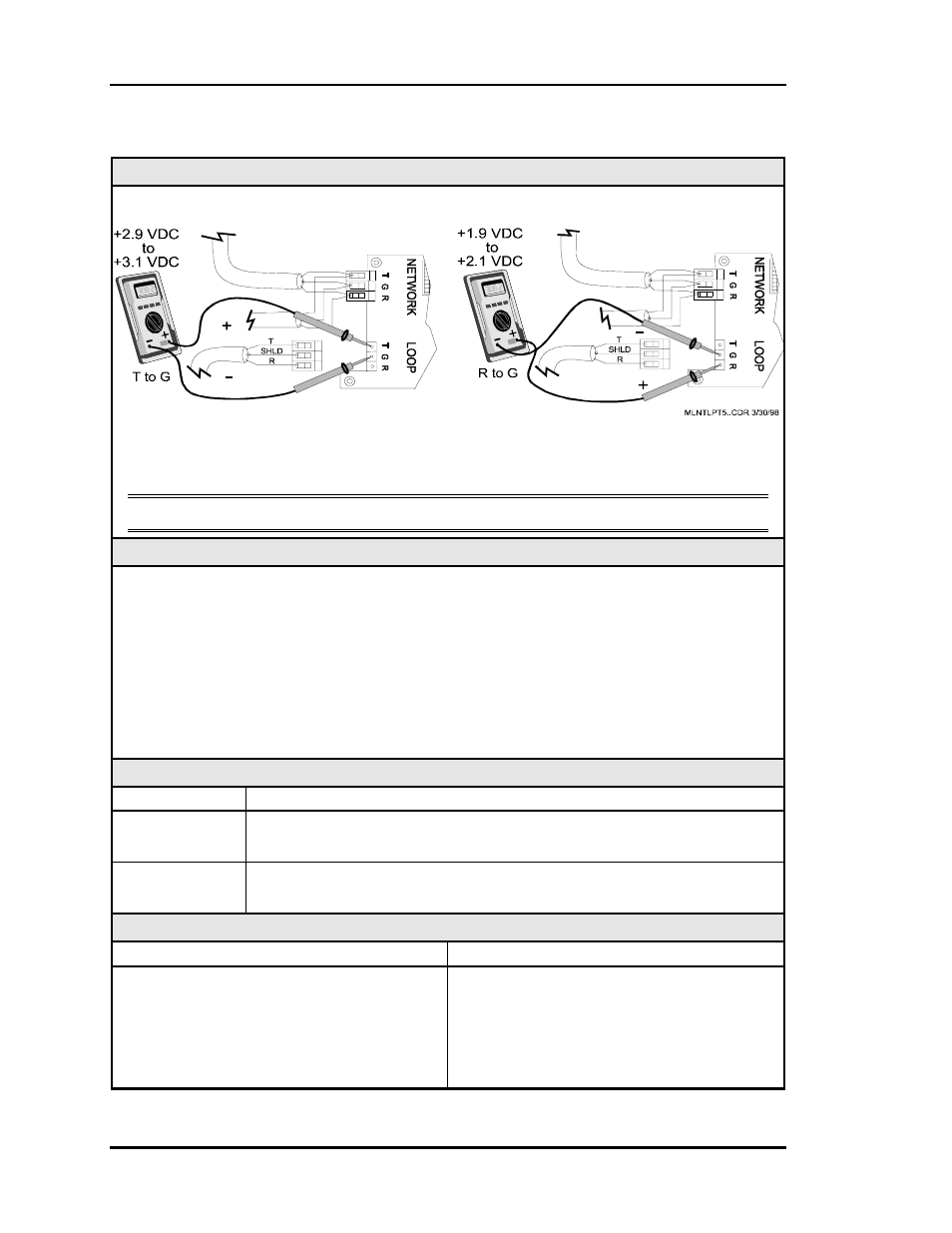

Checking the MiniLink Local Loop Driver

Diagram

Meter Set To Read DC Volts

The indicated values are typical of a normal operating system. Actual readings may deviate

slightly.

Note: These tests assume that the MiniLink is powered up.

Overview

This test checks for proper Local Loop voltages coming from the MiniLink.

Tip: The Local Loop LED (located near the connector) should “flicker” when the Mini-

Link is operating and when first powered up. If the LED is not flickering, the unit is

not functioning.

Proper loop voltages are essential for reliable communications. It is normal to see fluctua-

tions at this point on the MiniLink. The average value should be close to the acceptable

range described below. Values will vary upon initial powerup for about 10-15 seconds. The

voltage will fluctuate as the unit attempts to communicate.

Measurements

Local Loop

Acceptable Range

T – G

(SHLD)

2.9 - 3.1 Volts DC

R – G

(SHLD)

1.9 - 2.1 Volts DC

Action

Condition

Action

If voltages are too high or too low on either

side

1. The MiniLink has a damaged Comm

Driver chip. Locate and replace the

driver chip(s). See "1.3.11 Comm

Driver Chip Replacement”.

2. The MiniLink is not functioning.