Swagelok tube fittings, Retightening swagelok tube fittings, Installation – Parr Instrument 6100 User Manual

Page 11

Installation

6100

2

w w w . p a r r i n s t . c o m

9

procedure and calculations. The user should config-

ure the calorimeter at this time to accommodate the

desired sample weight entry mode. The calorimeter

can be placed into standardization mode on the

Calorimeter Operation Page, with the operating mode

key. If multiple bombs and buckets are being used

with the calorimeter to maximize sample through-

put, the calorimeter can be configured to prompt

for a Bomb ID at the start of each test. The Bomb ID

can also be selected on the Calorimeter Operations

Page, using the Bomb/EE key. Both bomb and bucket

combinations will need to be standardized separately.

The end result of a standardization test is an energy

equivalent value, or the amount of energy required to

raise the temperature of the calorimeter one degree.

Repeated standardization with any given bomb and

bucket combination should yield an energy equiva-

lent value with a range of 14 calories per degree,

centered around the mean value for all tests using

that bomb bucket combination. The calorimeter is

ready for testing samples after an energy equivalent

value has been obtained.

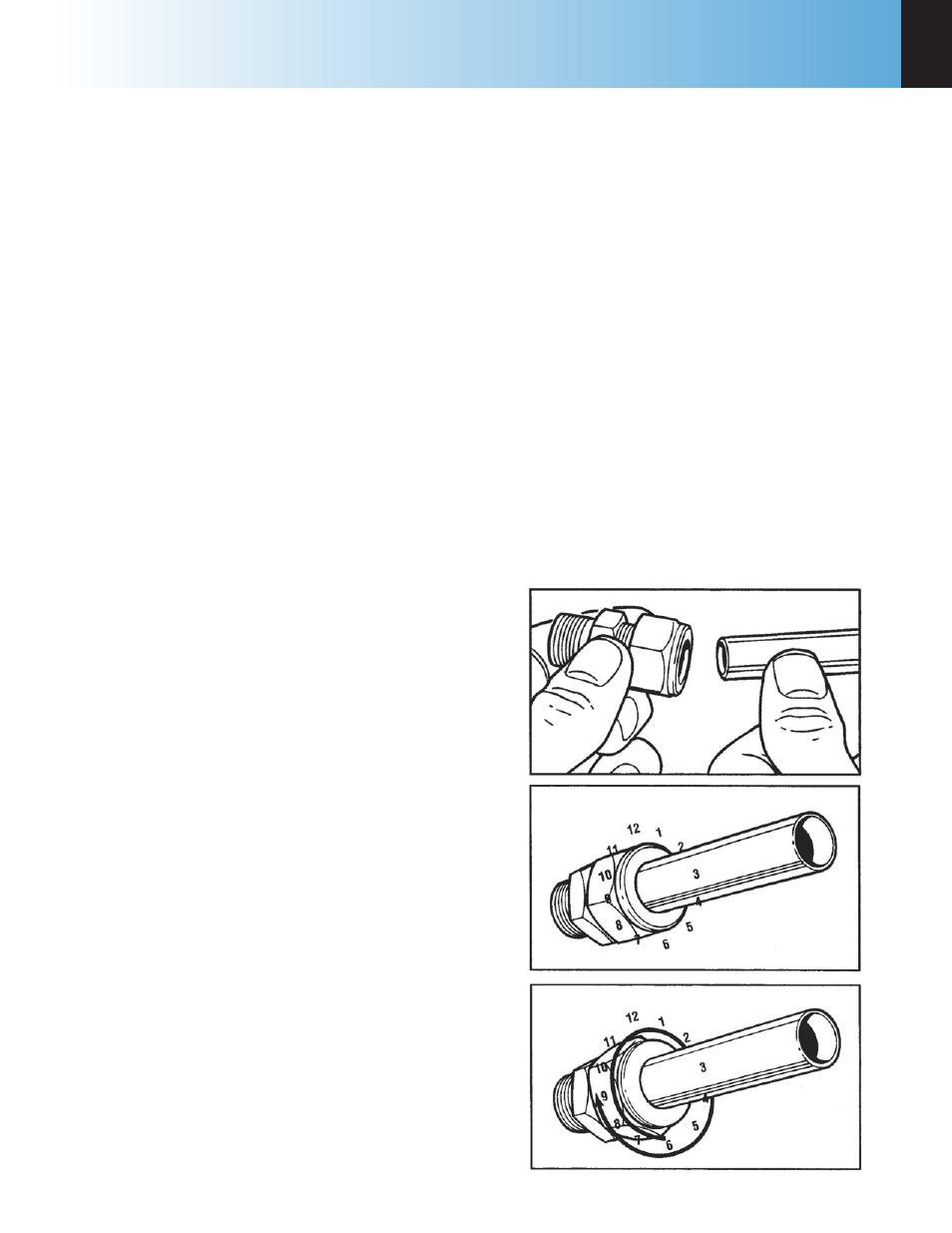

Swagelok Tube Fittings

When Swagelok Tube Fittings are used, the instruc-

tions for installation are:

1. Simply insert the tubing into the Swagelok Tube

Fitting. Make sure that the tubing rests firmly

on the shoulder of the fitting and that the nut is

finger-tight.

2. Before tightening the Swagelok nut, scribe the nut

at the 6 o’clock position.

3. While holding the fitting body steady with a back-

up wrench, tighten the nut 1-1/4 turns. Watch the

scribe mark, make one complete revolution and

continue to the 9 o’clock position.

4. For 3/16” and 4mm or smaller tube fittings, tight-

en the Swagelok nut 3/4 turns from finger-tight.

Retightening Swagelok Tube Fittings

Swagelok tubing connections can be disconnected

and retightened many times. The same reliable leak-

proof seal can be obtained every time the connection

is remade using the simple two-step procedure.

1. Insert the tubing with pre-swaged ferrules into the

fitting body until the front ferrule seats.

2. Tighten the nut by hand. Rotate the nut to the

Figure 2-1

Swagelok Tube Fittings

original position with a wrench. An increase in re-

sistance will be encountered at the original posi-

tion. Then tighten slightly with a wrench. Smaller

tube sizes (up to 3/16” or 4mm) take less tighten-

ing to reach the original position than larger tube

sizes. The type of tubing and the wall thickness

also has an effect on the amount of tightening re-

quired. Plastic tubing requires a minimal amount

of additional tightening while heavy wall metal

tubing may require somewhat more tightening. In

general, the nut only needs to be tightened about

1/8 turn beyond finger tight where the ferrule

seats in order to obtain a tight seal.

Over tightening the nut should be avoided.

Over

tightening the nut causes distortion (flaring) of the lip

of the tube fitting where the ferrule seats. This in turn

causes the threaded portion of the body to deform.

It becomes difficult to tighten the nut by hand during

a subsequent re-tightening when the fitting body

becomes distorted in this manner.