Hapter, Aintenance, Roubleshooting – Parr Instrument 6300 User Manual

Page 45: Routine maintenance — 45

M

AINTENANCE

& T

ROUBLESHOOTING

6300

9

w w w . p a r r i n s t . c o m

45

C

HAPTER

9

M

AINTENANCE

&

T

ROUBLESHOOTING

R

OUTINE

M

AINTENANCE

Note:

See the corresponding water system manuals for informa-

tion on the maintenance of those systems.

To service or remove the bomb cylinder from the bucket

assembly, remove the 941DD Wedge with needle nose

pliers. Remove the 668DD Check Valve from the bomb

cylinder. Remove the two SA1632RD18 Machine

Screws (see Figure F-20). Then remove the 942DD

Bushings and the 1081DD Quad-ring.

Carefully lift the bucket and bomb assembly out of the

air chamber and position horizontally on the calorim-

eter to remove the 925DD Oxygen Bomb Retainer Nut

(see Figure F-19). Now the cylinder can be removed

from the bucket assembly. Note the position of the

locating pin.

To replace, follow these steps in reverse.

Fuses

The replacement of protective fuses for the 6300

Calorimeter should be performed by qualified

personnel.

All fuses except Parr part # 139E23 are located on

the A2140E I/O board located inside the instrument.

Contact Parr Customer Service for instructions on how

to access the fuses.

Note:

Check the labels on the instrument for correct fuse rating.

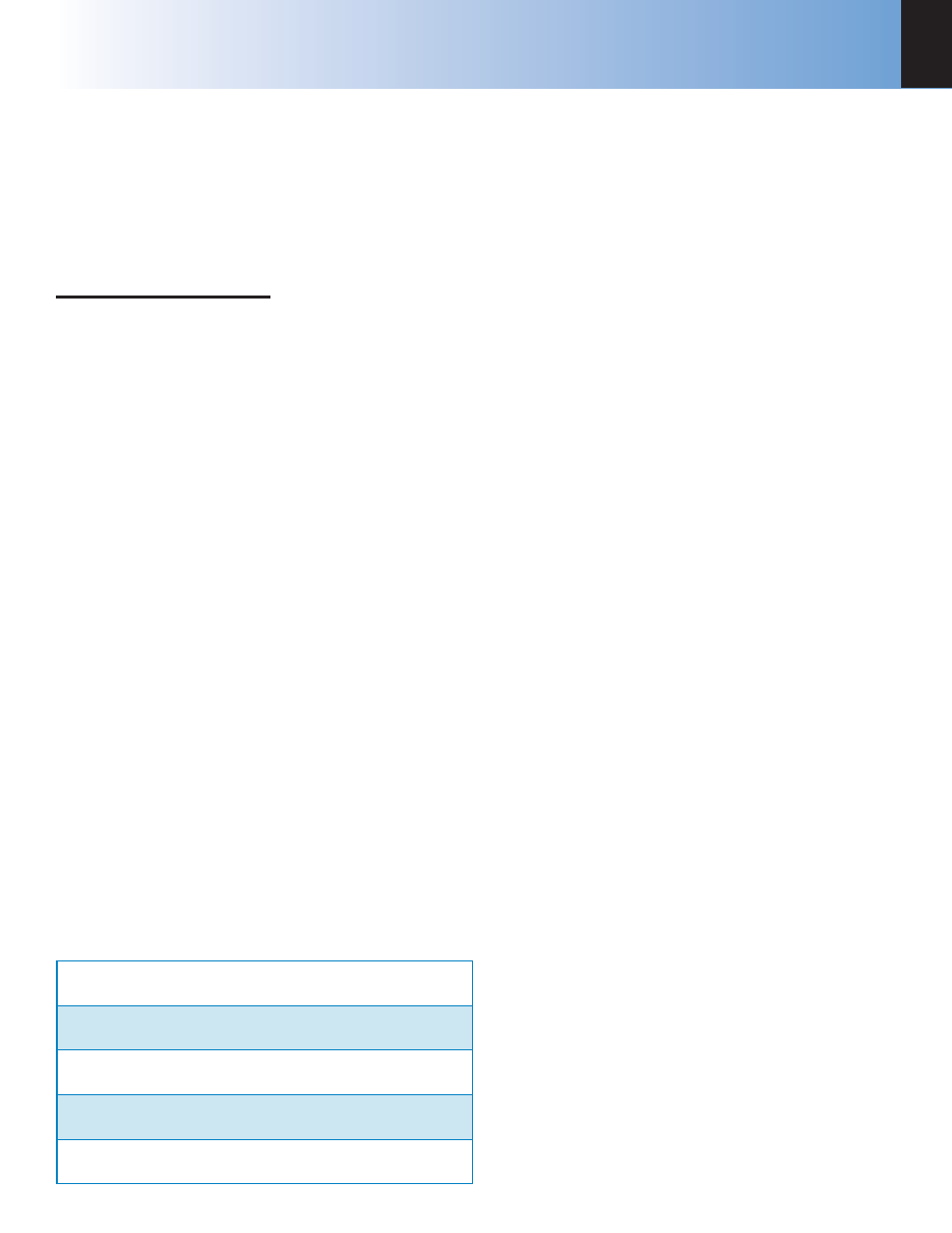

Parr

Part #

Description

Type

Ratings

139E23

Lines Protective

Fuses

Fast-Acting

15 Amps,

250Vac

1641E2

Heater Fuse (F2) Fast-Acting

2.5 Amps,

250VAC

1641E

Pump Fuse (F1) Fast-Acting

1 Amp,

250VAC

997E5

Bomb Rinse (F5) Slo-Blo

5 Amps,

250VAC

Daily Maintenance

Clean the 1444DDJB O-ring that seals the bomb head

and cylinder by wiping with a tissue. Wet this sealing

area with water prior to starting a series of tests. Clean

corresponding sealing area in cylinder in a similar

fashion. Both surfaces must be free of any accumulated

foreign matter, such as unburned sample material or

combustion by-products. Wet the hole in the center of

the head which contains the check valve.

With a tissue, clean the head where the large bucket

quad-ring contacts the head perimeter. Wet this sealing

area with water prior to starting a series of tests.

Remove, inspect and clean the cylinder check valve

(668DD) and corresponding sealing area in the bomb

cylinder. In extreme cases, i.e. a spilled sample, use soap

and water to clean the area.

50 to 100 Tests

Replace the heating wire, with 2.5” of 840DD2 360

degrees clockwise around screws. Clean 986DD

Electrode Contact Pins with mild abrasive, such as a

pencil eraser, clean bomb head electrode points in a

similar fashion, tighten screws holding heating wire in

place.

Quarterly

Change water in the Water Tank and replace the

1245DD and 149C water filters.

500 Tests

Under normal usage Parr oxygen bombs will give long

service if handled with reasonable care. However, the

user must remember that these bombs are continually

subjected to high temperatures and pressures which

apply heavy stresses to the sealing mechanism. The

mechanical condition of the bomb must therefore be

watched carefully and any parts that show signs of

weakness or deterioration should be replaced before

they fail.

Parr recommends that the following parts on the

oxygen bomb be changed every 500 tests or six months

whichever comes first: 840DD2, 1374HCJV (2),

394HC, 821DD (2), 1071DD, 1444DDJB, 659DD,

519AJV, 694DD. When reassembling the bomb head,

take care not to roll the 694DD O-ring as this will cause

an oxygen leak. Samples that contain chlorine or are