2 process and equipment messages – Martin Christ Alpha 1-2 LDplus User Manual

Page 54

Freeze-dryer Alpha 1-2 LDplus

7 Malfunctions and error correction

54

Version 11/2006, Rev. 2.0 of 02/12/2014 • sb

Translation of the original operating manual

Pos: 158 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 70 Stö run gen und Fe hlers uche /07 0-0 020 Proz ess un d Anla gen meld ung en LD plus @ 31\ mod _14 084 388 381 99_6 8.d ocx @ 209 732 @ 2 @ 1

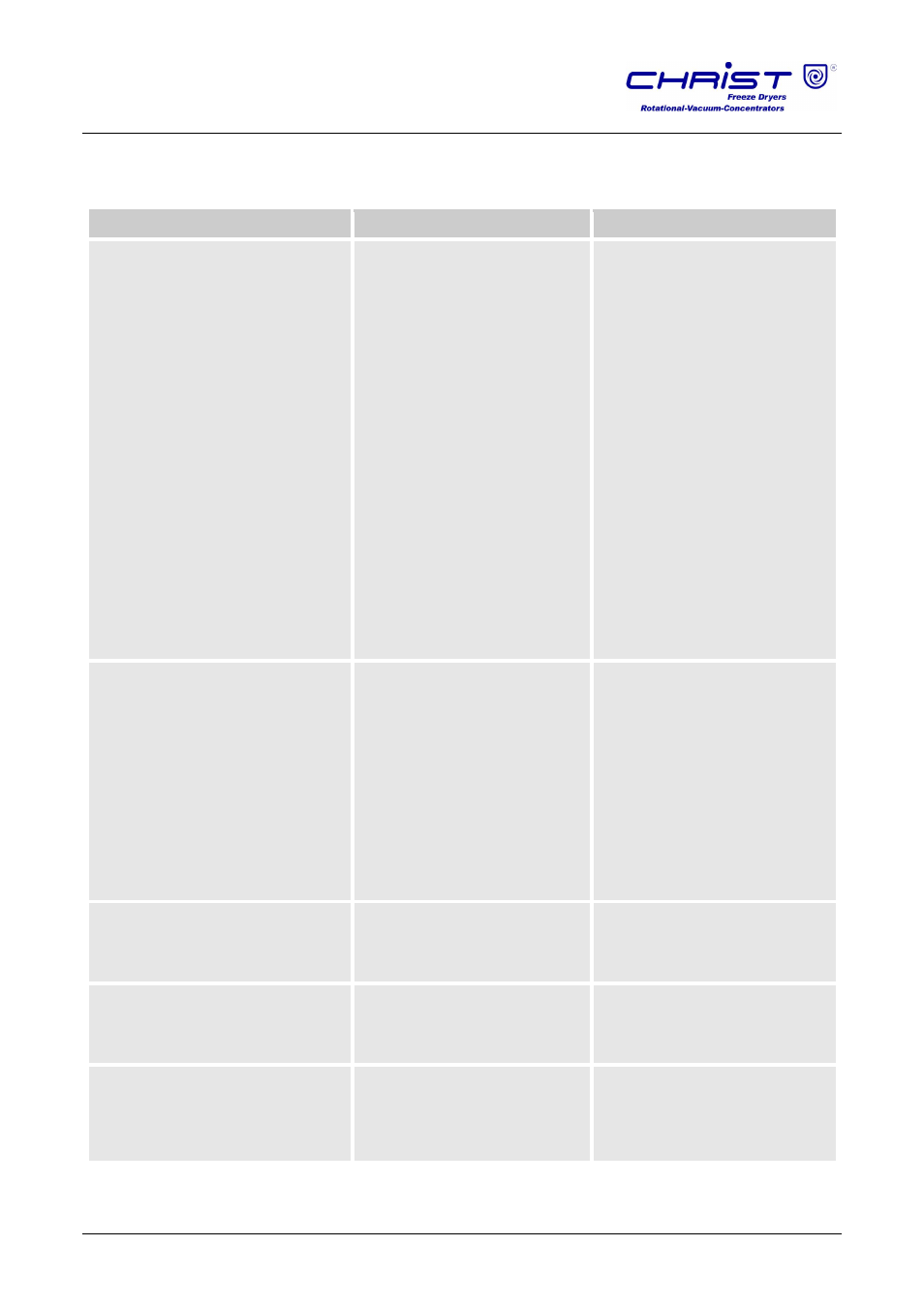

7.2 Process and equipment messages

Error message

Possible cause

Remedy

Vacuum 6.11 mbar not reached

The value of 6.11 mbar is not reached

within 15 minutes with an open pressure

control valve. The pressure control valve

will be closed and the vacuum pump will

be switched off.

• The aeration and media drain

valves are soiled.

• The small flange connections

are not properly connected.

• A seal is soiled or damaged.

• The cover or drying chamber is

not properly attached.

• The ground-in stopper is not

inserted correctly or it is

missing.

• The vacuum pump is switched

off or defective.

• Clean the valve (see chapter

8.1.1.3 - "Aeration valve, media

drain valve") and replace it if

necessary.

• Loosen the connection. Place

the centring ring with the inner

sealing ring in a centred manner

between the flange connections

and connect it with the clamping

ring. Ensure that the centring

ring neither slips out of place nor

gets jammed.

• Clean the seal and replace it if

necessary.

• Check the cover and drying

chamber.

• Grease the ground-in stopper

evenly and over the entire

sealing surface with vacuum

grease and install it.

• Switch the vacuum pump on.

Refer to the separate instruction

manual of the vacuum pump.

Defective vacuum sensor

The control system registers an invalid

measurement value.

• The vacuum sensor is not

connected correctly.

• The calibration is faulty.

• The vacuum sensor is soiled

(e.g. due to water residues).

• The vacuum sensor is

defective.

• Check the vacuum sensor

connectors.

• Calibrate the vacuum sensor

(see the separate operating

instructions of the vacuum

sensor).

• Clean the vacuum sensor.

• Check the vacuum display with

the aid of a reference device (if

available).

• See chapter 7.1.2.5 - "Vacuum

sensor".

Overpressure of refrigeration unit 1

• The overpressure switch of the

refrigeration unit has tripped.

• Let the freeze-dryer cool down.

• Ensure sufficient air circulation

(see chapter 7.1.3 - "Insufficient

ice condenser temperature").

Overpressure of refrigeration unit 2

• The overpressure switch of the

refrigeration unit has tripped.

• Let the freeze-dryer cool down.

• Ensure sufficient air circulation

(see chapter 7.1.3 - "Insufficient

ice condenser temperature").

Ice condenser overtemperature

Ice condenser temperature > +65°C. All

of the units will be switched off and the

freeze-dryer will be automatically set to

standby.

• The defrosting process has

been performed with the cover

closed.

• Remove the cover and let the

freeze-dryer cool down.