Top Flite TOPA0160 User Manual

Page 39

❏

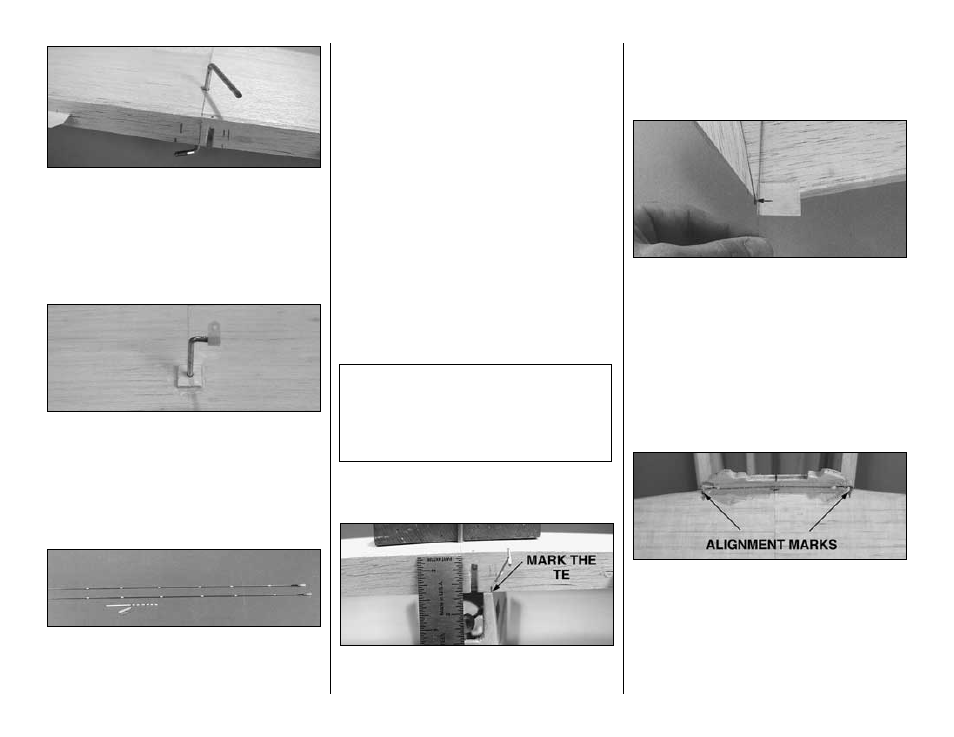

9. Insert the rudder torque rod into the hole in the

stab from the bottom. Use a heavy duty pair of pliers

to make the 90 degree bend in the torque rod. This

bend is not hard to make if you hold the vertical

portion of the torque rod with the pliers and then use

your thumb, or another pair of pliers, to bend the

torque rod over. Midway through the bend check that

it is 90 degrees to the threaded end of the rod.

❏

10. Make a 1/2” x 1/2” [12.7 x 12.7mm] bearing block

from some leftover 1/8” [3.2mm] ply. Drill a 1/8” [3.2mm]

hole in the center of the block and install it on the torque

rod on the bottom of the stab. Glue it in place with

medium CA, being careful not to get any on the torque

rod. Make sure that the nylon swivel horn has been

installed on the threaded end of the torque rod, with the

tab pointing towards the front of the stab.

❏

11. Cut 7” [177.8mm] from the non-threaded end

of a .074” x 36” [1.9 x 916mm] pushrod wire. Clean

residual oil from the wire with a cloth dampened with

alcohol or other solvent. Cut six 1/4” [6.4mm] long

bushings from the white inner pushrod tube, then

slide the bushings evenly spaced onto the wire.

Make sure the bushings at the ends of the wire will

not protrude from the guide tube or the control could

become stuck during flight. If the bushings slide onto

the wire easily, hold them in place with a drop of thin

CA. Make sure the CA cures before you proceed so

you do not inadvertently glue the pushrods into the

guide tubes! Slide a silicone retainer onto a nylon

clevis and thread the clevis onto the wire about 15

full turns. Make a second pushrod the same way.

❏

12. Cut the rudder pushrod tube, on the left side

of the fuselage, so that it extends only 2” [51mm] aft

of former F10. Connect one of the pushrods to the

nylon swivel horn on the rudder torque rod and slide

the silicone retainer into place. Slide the pushrod into

the rudder pushrod tube in the left side of the

fuselage. Slide the other pushrod into the elevator

pushrod tube. Position the stab on the stab saddle.

Place a weight on top of the stab to hold it in place.

CENTER THE STAB

❏

1. Align the TE of the stab with the center of former

F11. Mark the TE of the stab above the stab saddles.

Pin the stab TE to the stab saddle in this position.

❏

2. Insert a T-pin in the center of the top of

the firewall.

❏

3. Tie a loop on one end of a 54” [1372mm] piece

of string and connect it to the T-pin in the top of the

firewall. Put a piece of masking tape with an arrow on

it near the other end of the string. Slide the tape

along the string and align the arrow with the corner

of one of the stab halves. Swing the tape over to the

other corner on the other side of the stab. Shift the

stab and slide the tape along the string until the

arrow aligns with both corners of the stab.

❏

4. Mark the LE of the stab where it aligns with

former F10A.

Beech Quote: “The Beechcraft Bonanza is a

masterpiece of engineering; it’s an airplane that

constitutes a modern miracle of aeronautical

design; and in our opinion, marks a new milestone

in the progress of aviation.” —Walter H. Beech,

August 1, 1946

-39-