Top Flite TOPA0160 User Manual

Page 35

❏

5. Drill 3/16” [4.8mm] holes through the punch

marks in the die-cut 1/8” [3.2mm] plywood formers

F6 through F10. When you drill the holes, press

down on each former to prevent the wood from

splitting when the drill bit goes through. Also drill

3/16” [4.8mm] holes for the antenna tube in formers

F7 through F11.

❏

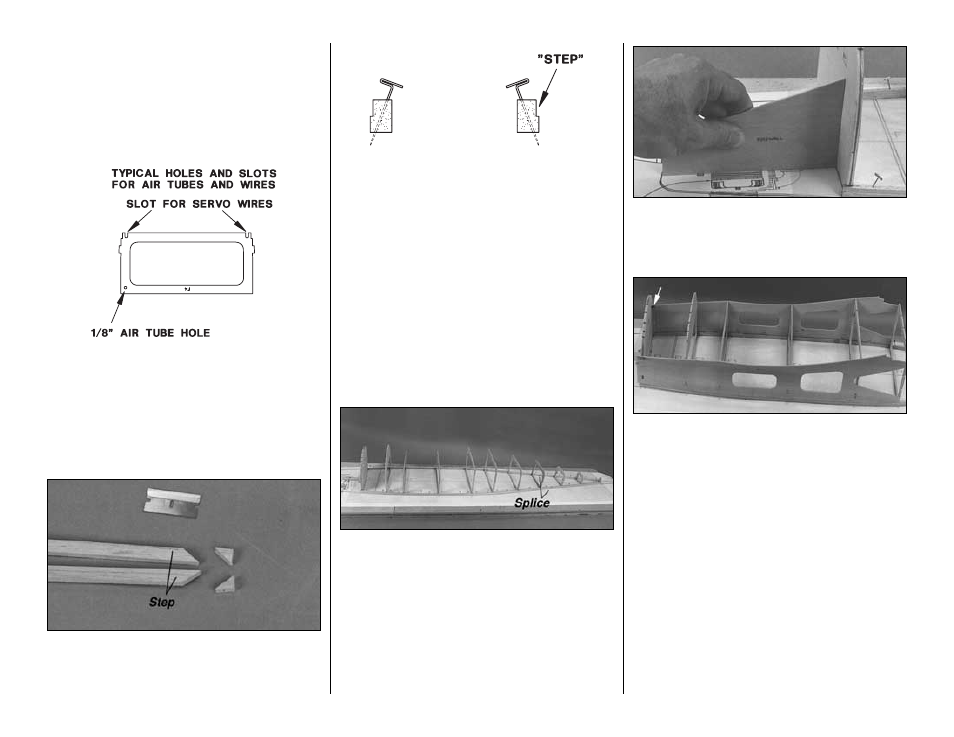

6. If you plan to install the Top Flite Beechcraft

T34B Scale Cockpit Kit (TOPQ8413), drill holes and

cut slots in the formers for routing the air lines and

servo wires between the fuse sides and the cockpit

interior in formers F3, F4 and F5.

BUILD THE BOTTOM OF THE FUSELAGE

❏

1. Cut a 45 degree angle at the aft end of two 1/4”

x 3/8” x 36” [6.4 x 9.6 x 914mm] stepped balsa side

stringers so you can

splice them onto another

stringer later.

❏

2. Pin the stringers over their location on the plan

so the

step is on the bottom and faces the outside of

the fuselage. The front end of the stringers should

align with the dashed lines near the front and

extend past the firewall by 1/8” [3.2mm]. Use plenty

of T-pins to hold the stringers down so they conform

to the curvature of the plan.

❏

3. Cut another 1/4” x 3/8” x 36” [6.4 x 9.6 x 914mm]

stepped balsa side stringer in half. Bevel one end of

both stringers to match the angles you cut on the

stringers already pinned to the plan. Pin these

stringers to the plan and glue them to the front stringers

with thin CA. Trim the ends so they extend past former

F11 by approximately 1/8” [3.2mm]. You can see the

splice in the following photo.

❏

4. Position but do not glue formers F1 through F11

on the side stringers so the embossed names on the

formers face forward. Adjust the stringers as needed.

Are your 3/16” [4.8mm] pushrod holes drilled?

❏

5. Glue formers F2 through F11 to the side

stringers, holding them vertical with a 90 degree

triangle. Don’t be concerned about formers that are

slightly warped or twisted–that is normal. You will be

able to straighten these formers when you glue the

3/16” [4.8mm] stringers to them.

❏

6. Glue the firewall to the side stringers using the

die-cut 1/8” [3.2mm] plywood firewall angle gauge

to hold the firewall at the correct angle. This will

establish the correct down thrust for the engine.

❏

7. Test fit, then glue the die-cut 1/8” [3.2mm]

plywood fuse side doublers to formers F2 through

F6 only and to the side stringers. Do not glue the

doublers to the firewall until the next step. You may

have to reposition some of your T-pins so they do not

interfere with the side doublers. Use your 90 degree

triangle to hold the formers vertical while you glue

the doublers to them.

❏

8. Glue the fuse side doublers to the firewall with

30-minute epoxy using the firewall angle gauge to

make sure the firewall is set at the correct angle. Use

a large C-clamp or masking tape to securely hold the

doublers to the firewall until the epoxy fully cures. Cut

one 3” [76.2mm] long piece from each of the (2) 1/2”

x 36” [12.7 x 914mm] balsa tri-stock pieces. Shape

the pieces so they fit between the firewall and the

fuse sides on both the left and right sides behind the

firewall. Glue them in place with 30-minute epoxy.

-35-