Top Flite TOPA0160 User Manual

Page 24

❏ ❏

17. Optional: From the plan cut off the two

paper tube strips along the dashed lines. Roll these

strips and cut them to the lengths needed. They are

used to allow easy routing of the servo wires and

their extensions. For fixed gear the tubes go from R2

to R9. For retracts they go from R7 to R9. For retract

installation, the wires can easily be fished through

the small holes in R4, R5 and R6.

❏ ❏

18. Cut three 3-1/16” [77.8mm] long servo

hatch cover rails from the 1/4” x 3/8” x 24” [ 6.4 x

9.6 x 610mm] basswood stick (the same stick you

used for the landing gear rail support if you are

building retracts). Glue the rails in the notches of the

ribs where shown on the plan.

❏ ❏

19. Cut three 1-1/2” [38mm] long flap hinge

blocks from the shaped 5/8” x 9” [15.9 x 229mm]

balsa stock. Bevel one end of each hinge block so

they fit the ribs, then glue them in the location shown

on the plan. See the cross section on the wing plan

to be sure you know the position and orientation of

the blocks.

❏ ❏

20. Cut five 1” [25.4mm] long aileron hinge

blocks from a 1/2” x 1/2” x 6” [12.7 x 12.7 x 152mm]

balsa stick. Cut one 2-7/8” [73mm] long hinge block

from the 5/8” x 1/2” x 6” [15.9 x 12.7 x 152mm] balsa

stick. The long hinge block is the one closest to the

root end of the aileron and is the base for the aileron

control horn.

❏ ❏

21. Bevel the ends of all the aileron hinge

blocks so they fit against the ribs as shown on the

plan. Bevel the tops of the hinge blocks that fit in the

aileron so they match the angle of the ribs. Glue the

hinge blocks in the wing and aileron.

❏ ❏

22. Use a bar sander and 80-grit sandpaper to

sand the sheeting, spars and LE so they are flush

with root rib W2 and tip rib W14.

❏ ❏

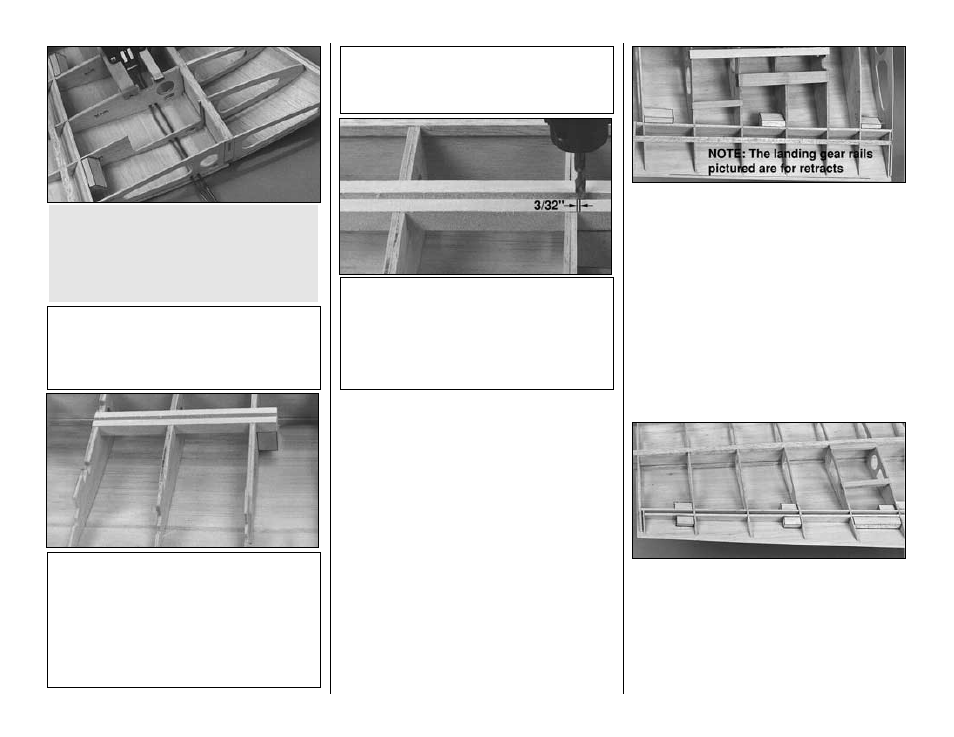

F16. After the epoxy on the landing gear rail

has fully cured, drill a 3/16” [4.8mm] hole through

the landing gear rail and the torque block. The

center of the hole should be 3/32” [2.4mm] from

the plywood rib doubler W4G. Make sure you hold

the drill perpendicular to the bottom of the landing

gear rail.

❏ ❏

F15. Cut the 1/4” x 1/2” x 9” [6.4 x 12.7 x

229mm] plywood flap servo hatch forward rail

to a length of 3-1/16” [77.8mm]. Glue it into the

notches of ribs W6 and W7.

❏ ❏

F14. Use 30-minute epoxy to glue the 1/2” x

3/4” x 6-3/4” [12.7 x 19 x 172mm] grooved

hardwood landing gear rail in the notches of the

ribs and rib doublers with the groove visible, as

shown in the photo. At the same time, glue the

3/4” x 3/4” x 1” [19 x 19 x 25.4mm] maple torque

block to rib doubler W4G and the top of the

landing gear rail.

Perform steps F14-F16 if you are installing fixed

landing gear.

NOTE: The fixed landing gear rail and rib

doublers are shown on the left wing plan.

❏ ❏

R13. Now is a convenient time to plan your

air line routing. If you haven’t already done so,

drill or cut holes in the ribs to guide the air lines.

A 5/32” [4mm] brass tube sharpened at one end

makes a great

drill to cut holes through the ribs.

Do not install the air lines at this time.

-24-