Top Flite TOPA0415 User Manual

Page 50

❏

9. Once you have positioned the cowl mounts and

the cowl rings, remove one of the cowl ring sections,

add medium CA, then carefully reposition the cowl

ring, permanently gluing it into position. Glue the

remaining five cowl ring sections into position the

same way. Do not glue the cowl mounts to the

fuselage until after the fuse is covered.

❏

10. Remove the cowl mounts. Sand the cowl ring

sections even with the fuselage. Round the edges as

shown on the plan. As you can see, this is easily

done with the cowl mounts off the model.

❏

11. Reposition the cowl mounts to the fuse. Drill

1/16" holes through the elongated holes in the cowl

mount bases and into former 1. Temporarily hold the

cowl mounts in position with six #2 x 3/8" screws and

#2 washers. The cowl mounts will be permanently

glued in place after the model is covered.

❏

12. Cut six 1" x 1" squares from the leftover 1/32"

ply sheeting (from the flap area of the wing). Glue the

squares to the inside of the cowl where they will align

with the cowl mounts.

❏

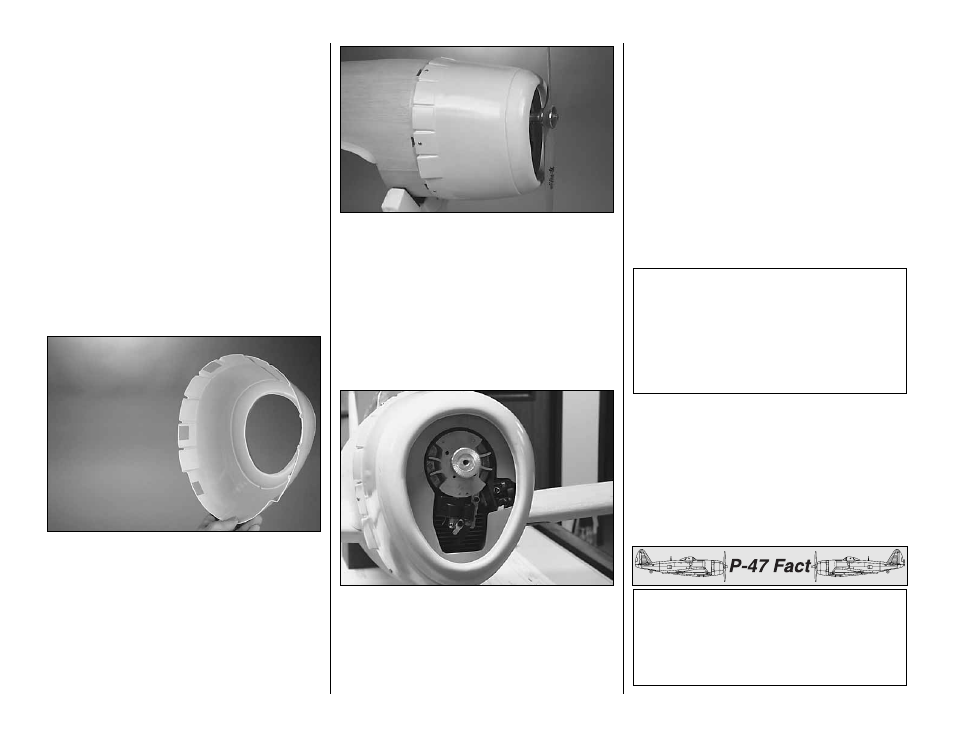

13. Mount the engine to the fuse. Place the cowl on

the fuse and mount a prop on your engine. Align the

cowl so the prop will have clearance all the way

around and is centered on the engine. View the

alignment of the cowl with the engine and the fuselage

from all angles. Make adjustments as needed.

❏

14. Have an assistant hold the cowl in position, or

use masking tape. Drill 3/32" holes through the cowl

and the cowl mount blocks. Remove the cowl and

enlarge the holes in the cowl only with a 5/32" drill.

Add a few drops of thin CA to all the holes and allow

it to harden.

❏

15. Test mount the cowl to the cowl mounts with

six #6 x 1/2" screws and #6 washers.

Refer to this photo while building the engine

baffle in the next few steps.

❏

16. Now that you’ve mounted the cowl, use the

template on the plan to make an engine baffle from

1/8" lite plywood (not included). The baffle will guide all

incoming air over the head and cylinder of the engine

for maximum cooling. The cutout is for the US Engine

41cc. If you are using a different engine, you’ll have to

make the cutout by trial and error fitting.

❏

17. Test fit, then temporarily tack-glue the baffle

into the cowl against the lip that joins the cowl front

to the sides. Trim as necessary for a good fit.

❏

18. Fit the cowl to the engine, trimming the

opening in the baffle as necessary until you have

achieved adequate clearance all the way around.

❏

19. Remove the cowl. Determine the location of

accessories to be mounted inside the cowl, such as an

ignition switch (if using an ignition engine), fueling

system, remote glow igniter, air fill valve, etc.Temporarily

mount those items where you prefer, then cut holes in

the cowl to access them. Cut additional holes where

necessary for the exhaust outlet and the needle valve.

❏

20. Glue the baffle to the cowl. Reinforce the seam

between the cowl front and sides with several 3-inch long

strips of 1" glass cloth and 30-minute epoxy. Reinforce the

seams on the top and bottom of the cowl sides and around

the cowl flaps with additional strips of 1" glass cloth and

epoxy. While you’re at it, use some of the leftover epoxy to

lightly coat the plywood baffle so it will be fuelproof and water

resistant when wet-sanding the cowl.

With demand for P-47’s beginning to exceed

production capabilities at the Evansville and

Farmingdale plants, a third factory was needed.

Under license, the Curtiss Aircraft Company in

Buffalo, NY, began production on the P-47G,

identical to P-47D’s.

Note: IMAA rules specify that magneto spark

ignition engines must be equipped with a manually

operated coil-grounding switch to stop the engine.

This switch must be mounted in a location that is

readily available to both the pilot and the helper. As

mentioned in the front of the manual, Great Planes

makes an Ignition Switch Harness (GPMG2150)

that is suitable for this purpose.

-50-