Top Flite TOPA0415 User Manual

Page 12

❏

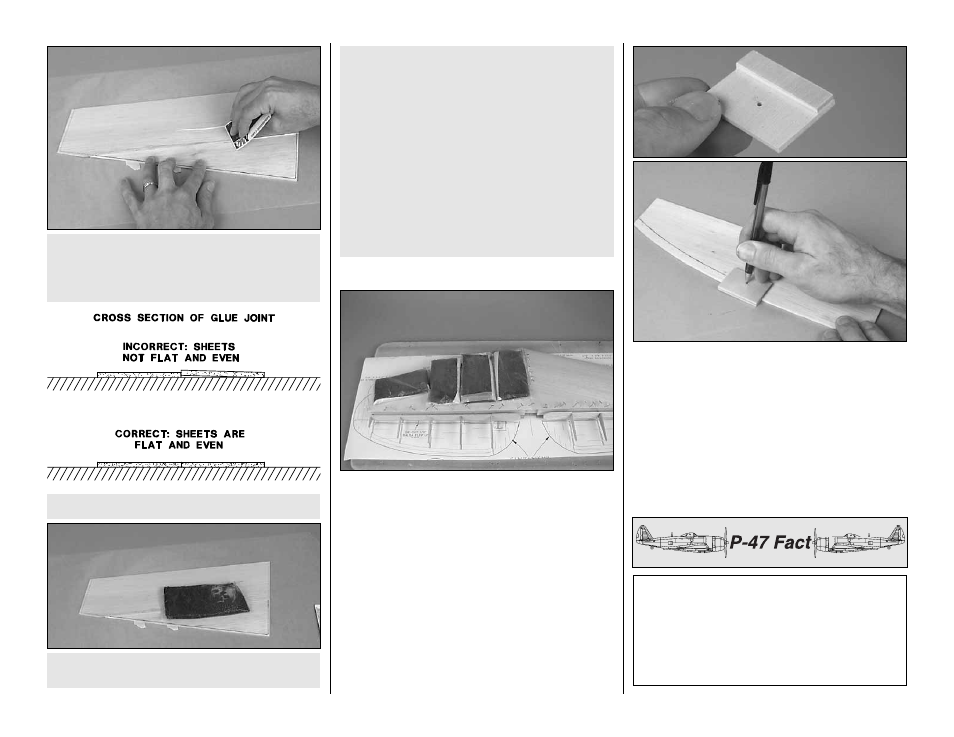

17. Glue two stab skins to the top of the stab using

aliphatic resin or medium or thick CA. Our preferred

method is to apply aliphatic resin to the tops of the

ribs and the TE, then position the skin and hold it

down with weights and T-pins where necessary.

Before the glue dries, use thin or medium CA to glue

the front of the skin to the LE.

❏

18. Use the template on the plan to make the

elevator skins from two 3/32" x 4" x 24" balsa sheets.

Hint: Use 3M 75 Repositionable Spray Adhesive to

stick the paper template to the balsa sheet, then cut

it out. If you have a band saw or a scroll saw, stack

all four sheets together with 3M 75 and cut them out

all at once.

❏

19. Make the bevel gauge from the die-cut 1/8"

plywood pieces, then drill a hole at the punch mark

just large enough to fit the tip of a ballpoint pen. Use

the bevel gauge to mark the bevel lines on the inside

of the TE of all four elevator skins with a ball-point pen.

❏

20. Using the line as a guide, bevel the elevator

skins down to approximately 1/32" at the trailing edge.

The P-47 had many attributes that led to its

reputation. One of the most important was its

durability in combat. Oftentimes the P-47 would

bring pilots home with missing cylinders, blown-off

wing tips and large portions of tail surfaces missing.

The P-47’s internal systems were also durable and

well protected.

G. After the glue dries, sand the skins flat and

even. Little sanding should be required.

Note: Some modelers tend to sand the sheeting

too much after it is applied to the structure,

making thin spots where fingers can easily go

through. By following the procedure above

(specifically, by aligning the skins as shown in

step E), little sanding should be required. Most of

the sanding that

is required should be done

before the sheeting is glued in place. The only

sanding that should be required after the skin is

glued to the structure is final sanding with 320- or

400-grit sandpaper.

F. Place a weight on top of the skin to hold it flat

while the glue dries.

E. Press the edges down so they are even.

D. Cover your workbench with wax paper and lay

the skin on it. Use a credit card or something

similar as a squeegee to simultaneously press the

sheets flat as you wipe the glue from the seam.

-12-