Top Flite TOPA0415 User Manual

Page 19

an additional 3/32" x 4" x 36" balsa sheet for the left

side. Glue the first sheet to the right side of the fuse.

Do not glue the sheeting to the stab saddle. If

necessary, wet the sheeting with water or window

cleaner to help it bend around the formers. Glue the

other sheet to the left side of the fuse.

❏

4. Trim the sheeting even with the stab saddles.

Use caution not to trim the ply stab saddles.

Otherwise, you may change the incidence of the stab

which will greatly affect the flying characteristics.

Before we can sheet the rest of the fuse, we have to

glue the stab and fin into position.

❏

5. Fit the stab into the stab saddle. Trim the fuse

sheeting and the stringers as necessary until the TE

of the stab aligns with the dotted line on the plan

depicting the TE. Place a weight on top of the stab to

temporarily hold it down.

❏

6. With the stab in position, measure the distance

from the centerline on the TE of both ends of the stab

down to your workbench. If necessary, lightly trim

the stab saddles until you can get the stab level. If

the stab is not exactly level, but it’s close, sometimes

all it takes is shifting the weight slightly to even it up.

If you do have to sand the saddle to level the stab,

use caution not to change the incidence angle of

the stab.

❏

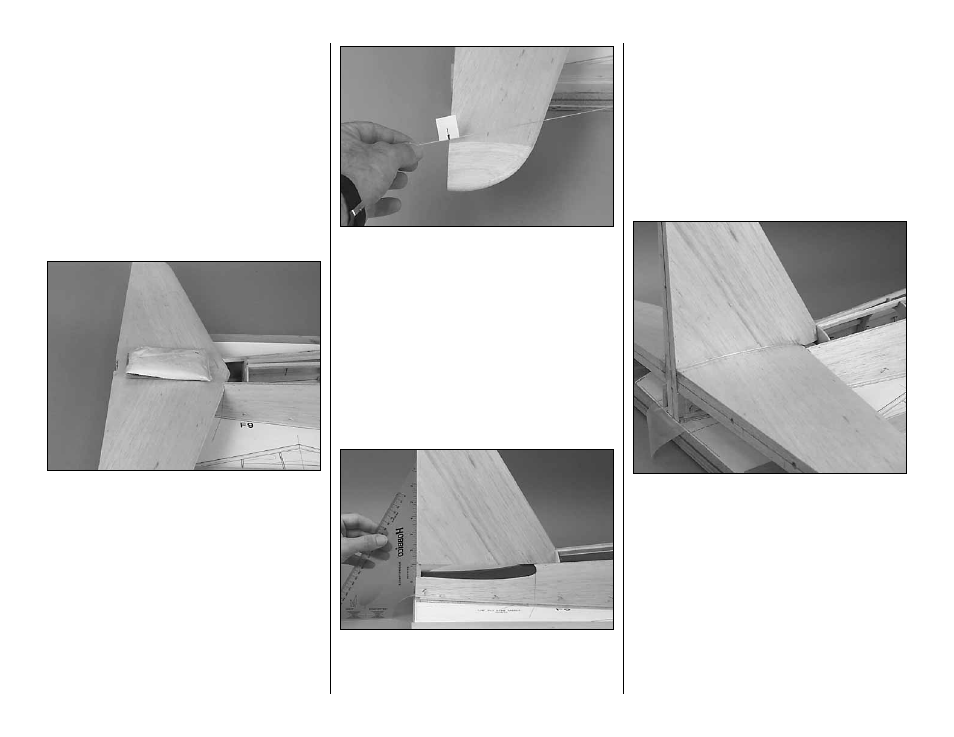

7. Stick a T-pin into the center fuse stringer above

former 1. Tie a small loop in one end of a 60" piece

of string and slip it over the T-pin. Fold a piece of

masking tape over the string near the other end and

draw an arrow on it. Sliding the tape along the string,

align the arrow with one end of the stab as shown in

the photo. Swing the string over to the same position

on the other side of the stab. Shift the stab and slide

the tape along the string until the arrow aligns with

both sides of the stab. The stab must remain

centered on the fuse during this process.

❏

8. Mark the stab where it aligns with the fuse so it

can be realigned after you take it off.

❏

9. Remove the stab. Trim the sheeting on the LE of

the fin until you can get it to fit into the notch in former

9. Use a builder’s square to make sure the fin TE will

be perpendicular to the building board in both axes.

❏

10. Remove the fin. Mix up a batch of 30-minute

epoxy. For additional strength, add Great Planes

Milled Fiberglass (GMR6165). Apply a small fillet of

epoxy to strengthen the bond between the insides of

the stab saddles and the main stringers and former 9.

Apply epoxy to the stab saddles and fuse sheeting

and to the bottom of the stab where it contacts the

saddles. Position the stab and place weights on top of

it to hold it down. Confirm stab alignment by repeating

steps 5 and 6. Wipe away excess epoxy and do not

disturb the model until the epoxy fully cures.

❏

11. After the epoxy from the previous step has

fully cured, fit the fin to the stab by trimming the

bottom of the sheeting until it fits the stab and can be

positioned as described in step 9 (with the TE

vertical and contacting the stab saddles). The TE of

the fin must be even with the TE of the stab.

❏

12. Mix up another batch of 30-minute epoxy and

securely glue the fin to the top of the stab and fuse.

Be certain the fin sheeting is thoroughly bonded to

the stab, but don’t build up a large fillet. Now glue the

top two stringers to former 9.

Now that the stab and fin are glued to the fuse, we

can finish sheeting the fuse.

-19-