Top Flite TOPA0415 User Manual

Page 26

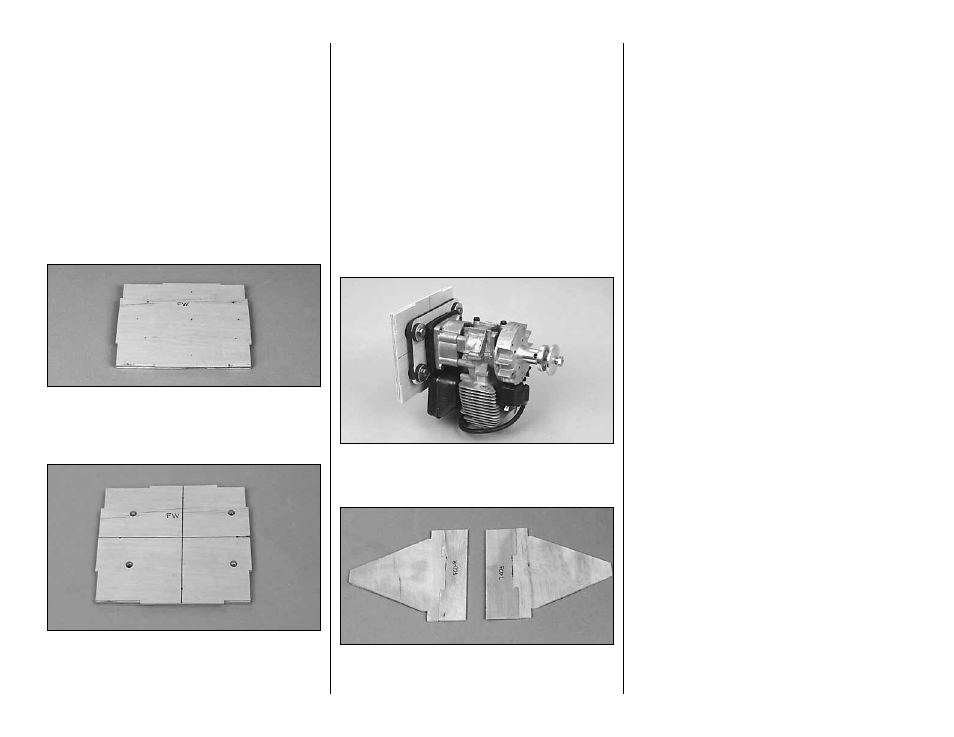

Mount the engine

The instructions show a U.S. Engines 41cc engine

and a Great Planes Isolation Mount. Other engines

are suitable, provided they are within the

recommended range, but may require a different

engine mount. Keep in mind that you can rotate the

engine to conceal the muffler inside the cowl and to

aim the engine exhaust where you want (the engine

doesn’t have to be mounted exactly inverted). Just

make sure the mount is centered on the reference

lines on the firewall and that the orientation you have

chosen will allow sufficient air flow over the head

and cylinder.

❏

1. Use 30-minute epoxy to glue the die-cut 1/8"

plywood forward firewall (FW) to the 1/4" x 6-1/8" x

5-1/2" plywood aft firewall. From now on this

assembly will be referred to as the firewall.

❏

2. Drill four 19/64" (or 5/16") holes through the

outer punch marks in the firewall only if you are

using a Great Planes Isolation Mount. If you are

using another engine mount, use a ballpoint pen and

a straightedge to draw lines connecting the four

inner punch marks. Center the engine mount on the

cross marks, then mark and drill the appropriate size

holes for the engine mount.

❏

3. Tap blind nuts into the back of the firewall

through the holes you drilled. Secure the blind nuts

to the back of the firewall with CA.

❏

4. Use the drawing of the Isolation Mount on the fuse

plan to mark the location of the mounting holes for

mounting your engine. Trim the bottom of the mount

along the lines. Drill 1/4" holes through the iso plate and

temporarily mount your engine with 1/4-20 x 1-1/4"

bolts and flat washers (not included with this kit).

❏

5. Temporarily mount the iso plate with the engine

to the firewall to confirm that the mounting holes

align. Make adjustments if necessary.

❏

6. Glue together both sets of die-cut 1/8" plywood

parts that make up the right and left fuse

crutch doublers.

❏

7. Test fit the doublers to the crutches in the fuse,

then test fit the firewall. Be certain the firewall will fit

all the way into the notches of the crutches. If it

doesn’t, trim the forward edges of the crutch

doublers as necessary.

❏

8. After adjustments have been made, glue the

crutch doublers to the crutches with 30-minute epoxy.

❏

9. Remove the iso plate from the firewall. Glue the

firewall into position with 30-minute epoxy. Use

masking tape or clamps to hold the firewall in place

until the epoxy cures. If you don’t have clamps that

are big enough, use #2 x 1/2" or 3/8" screws to hold

the crutches to the firewall. We used flat head screws

on our prototype and countersunk them into the

crutches. Work neatly and don’t build up a large fillet

of epoxy behind the firewall because we’re going to

add reinforcing triangle stock in the next step.

❏

10. Use the 1/2" x 24" basswood triangle stick

to reinforce the glue joint between the four sides of

the firewall and the inside of the fuse crutches and

the tank roof and floor. Glue the sticks into position

with epoxy.

❏

11. Further reinforce the glue joint by drilling 3/32"

holes through the crutches, tank floor and tank roof

into the edges of the firewall. “Pin” it all together with

round toothpicks glued in place with epoxy.

-26-