Isobus job computer : ic18 sprayer, Regulation parameters – TeeJet IC18 SPRAYER JOB COMPUTER User Manual

Page 23

18

www.teejet.com

OVER

VIE

W

SE

TUP

APPENDIX

GE

TTING ST

AR

TED

OPER

ATION

ISOBUS Job Computer : IC18 Sprayer

Regulation Parameters

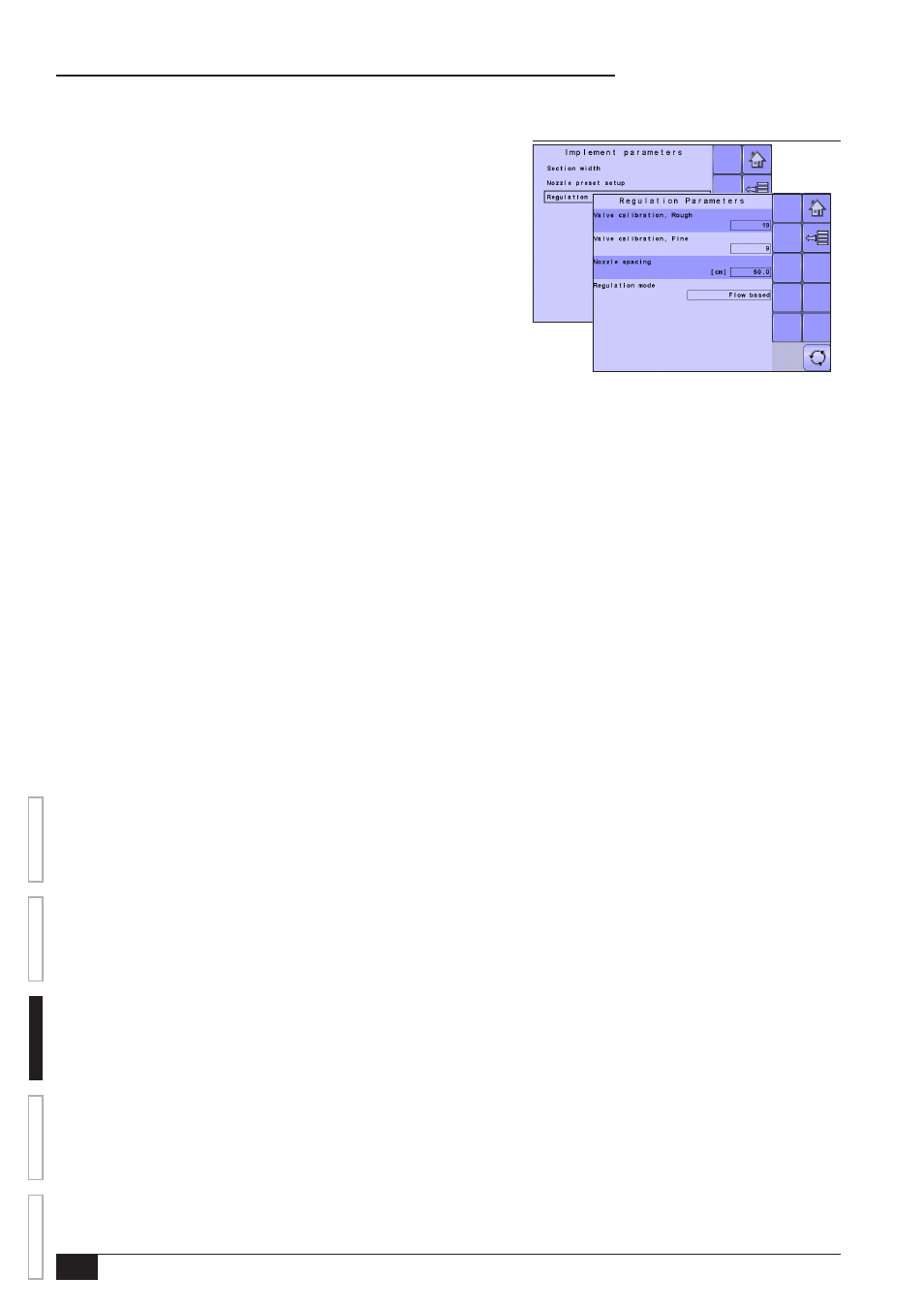

Figure 3-22: Regulation Parameters

Regulation Parameters establishes adjustments to the valve calibrations, nozzle

spacing and regulations mode.

NOTE: Adjusting the Valve Calibration settings involves significant changes and

adjustments should therefore be made in small steps.

Valve Calibration, Rough

Rough regulation value calibration allows you to regulate the setting of the

regulating valve to accommodate different application needs. Operating conditions

may necessitate a higher or lower response setting for the regulating valve. This

value adjusts the setting for coarse adjustments in relation to a large percentage

outside of the target application rate

►If the system is too slow in finding the correct rate, the values should be

increased.

►If the system is too unstable, the values should be decreased.

• To select the Valve Calibration, Rough, use the number pad or slide bar.

If your system is plumbed in a bypass mode, the valve setting number of 9 works very well in most applications

If your system is plumbed in a throttling mode, start with a valve setting number of 3 and adjust the number according to your application

requirements. Low flow situations will require a slower response time. Adjusting agitation volumes to accommodate the regulating valve to

work in a more fully open position allows for a faster response time, with little to no searching.

NOTE: This setting value can be adjusted to optimize system performance. If you notice that the valve seems to “search” for the

programmed application rate by cycling the pressure up and down continuously, reduce the number until the “searching” is

minimized or eliminated. Conversely, a higher number will increase the valve response time and “speed up” the rate of adjustment.

Valve Calibration, Fine

Fine regulation value calibration allows you to regulate the setting of the regulating valve to accommodate different application needs.

Operating conditions may necessitate a higher or lower response setting for the regulating valve. This digit adjsuts the setting for the fine

tune adjustment in relation to a small percentage close to the target application rate.

►If the system is too slow in finding the correct rate, the values should be increased.

►If the system is too unstable, the values should be decreased.

• To select the Valve Calibration, Fine, use the number pad or slide bar.

If your system is plumbed in a bypass mode, the valve setting number of 5 works very well in most applications.

If your system is plumbed in a throttling mode, start with a valve setting number of 3 and adjust the number according to your application

requirements. Low flow situations will require a slower response time. Adjusting agitation volumes to accommodate the regulating valve to

work in a more fully open position allows for a faster response time, with little to no searching.

NOTE: This setting value can be adjusted to optimize system performance. If you notice that the valve seems to “search” for the

programmed application rate by cycling the pressure up and down continuously, reduce the number until the “searching” is

minimized or eliminated. Conversely, a higher number will increase the valve response time and “speed up” the rate of adjustment.

Nozzle Spacing

Nozzle Spacing establishes the distance between the nozzles on the boom.

• To select the Nozzle Spacing, use the number pad or slide bar.

Regulation Mode

Regulation Mode determines if the rate control is pressure based or flow based.

• To select the Regulation Mode, select an option from the drop down menu or use the UP/DOWN ARROWS to highlight the option.