Isobus job computer : ic18 sprayer, Chapter 3 – main setup in sprayer mode, Main setup mode menu structure – TeeJet IC18 SPRAYER JOB COMPUTER User Manual

Page 13: Main setup screen

8

www.teejet.com

OVER

VIE

W

SE

TUP

APPENDIX

GE

TTING ST

AR

TED

OPER

ATION

ISOBUS Job Computer : IC18 Sprayer

CHAPTER 3 – MAIN SETUP IN SPRAYER MODE

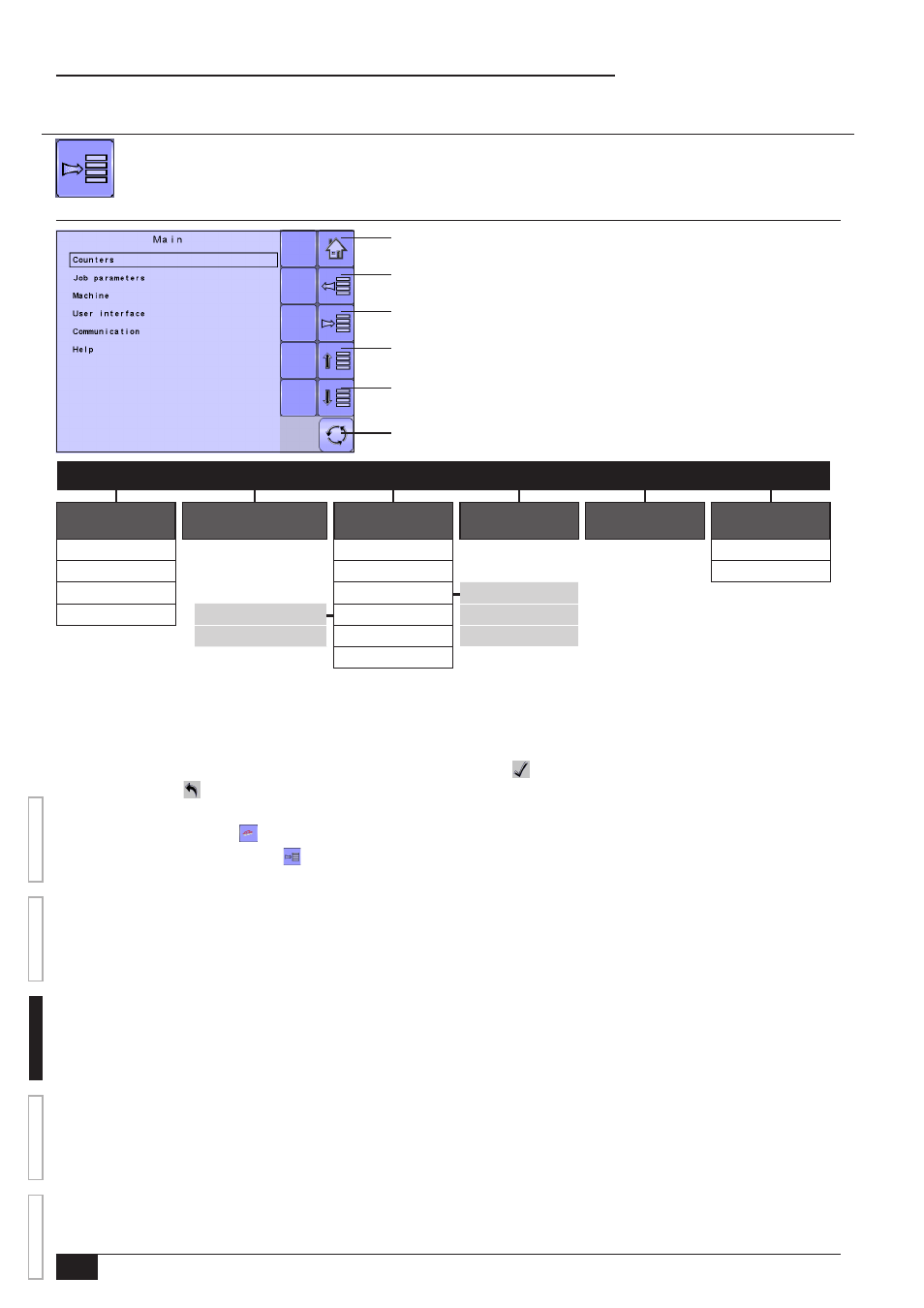

Main Setup Mode configures the Counters, Job Parameters, Machine, User Interface, Communication and Help options.

NOTE: The menu structure on your display might vary from the one displayed in this User Manual depending on the virtual

terminal being used.

Figure 3-1: Main Setup Screen

Home Key

Back One Screen

Up One Option

Down One Option

Master Screen Key

Forward One Screen

MAIN SETUP MODE MENU STRUCTURE

|

|

|

|

|

|

Counters

(pages 10-12)

Job Parameters

(pages 13)

Machine

(pages 14-20)

User Interface

(pages 21)

Communication

(pages 22)

Help

(pages 22-24)

Trip

Filling

Diagnostic

Campaign

Operation

About

Total

Implement parameters – Section width

Export Counters

Implement speed sensor – Calibrations

Nozzle preset setup

Flow sensor

Alarm configurations

Regulation parameters

OEM

The OEM setup menu is password protected and the settings in this menu are directly related to the fitted OEM equipment. Refer to the IC18 Sprayer/NH3 OEM Setup

Manual

for information regarding OEM settings.

Main Setup Screen

NOTE: Settings are NOT automatically saved when selected. The ACCEPT KEY must be selected to save the setting. Select the

ESCAPE KEY to escape without saving settings and return to the previous menu.

To access the Main Setup screens:

1. Select IC18 SPRAYER KEY from the Master Screen.

2. Select MAIN SETUP SCREEN KEY from the Home Screen.

3. Select from:

►Counters – used to provide an overview of various system counters:

◄ Trip – used to display information regarding area, distance, time and amount applied.

◄ Campaign – used to display information regarding area, amount applied and time for all trips

◄ Total – used to display information regarding area, amount applied, and time for all activity

◄ Export Counters – allows counter information to be exported in HTML or CSV format

►Job Parameters – used to configure application settings including active trip counter, application rate and nozzle type.

►Machine – used to configure machine settings:

◄ Filling – establishes the amount of material remaining in the tank and the density of that material.

◄ Operation – establishes Application Rate Step, Speed Source, and Simulated Speed

◄ Implement Parameters – establishes the Section Width, Nozzle Preset Setup and Regulation Parameters

◄ Calibrations – establishes either manual or automatic settings of the sensors

◄ Alarm Configurations – establishes alarms for CAN Speed Source Timeout, Active Trip Count Information mode and Tank

Content Minimum

◄ OEM – The OEM setup menu is password protected and the settings in this menu are directly related to the fitted OEM

equipment. Refer to the OEM Setup Manual for information regarding OEM settings.