3 troubleshooting the heat section, 0 troubleshooting (cont'd) – Reznor YDSA Operation Manual User Manual

Page 46

Form O-Y, PN 273647R1, Page 46

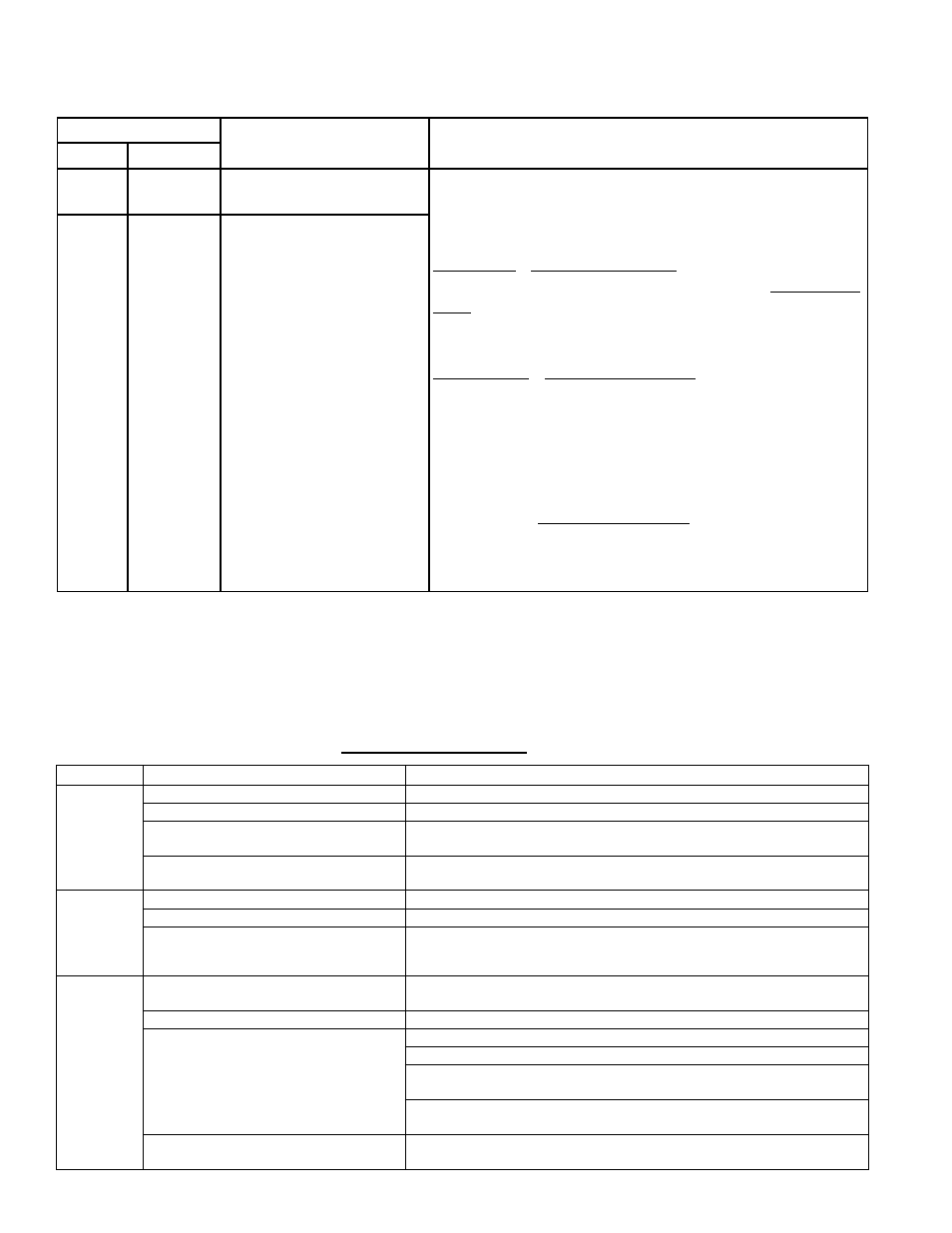

PROBLEM

PROBABLE CAUSE

REMEDY

Unit does

not operate

1. No power to unit

1. Turn on power; check supply fuses or main circuit breaker.

2. Blown fuses

2. Check and replace if necessary.

3. Defective or incorrect wiring.

3. Check wiring and connections. Refer to wiring diagram provided with

unit.

4. Defective or burned out control

transformer

4. Check secondary voltage with voltmeter. Replace if necessary.

Fan

operates

but element

does not

heat

1. Dirty filters

1. Check filters and clean or replace if necessary.

2. Defective air proving switch

2. Check and replace if necessary.

3. Blown element fuses

3. Check and replace element fuses if necessary.

Insufficient

heat

1. Burned out element

1. Turn off power and check element resistance with ohmmeter. Replace

if open.

2. Blown fuses

2. Check and replace if necessary.

3. Cycling on limit control

3.

a) Check air throughput (temperature rise).

b) Check motor rpm against nameplate rating. Replace motor if speed is

too slow.

c) Defective limit control. Check wiring and connections. Check continuity

through control and replace if necessary.

4. Defective or incorrect wiring.

4. Check wiring and connections. Refer to wiring diagram provided with

unit.

7.3 Troubleshooting the Heat Section

7.3.1 General Troubleshooting - Electric Heat Section (Option E__)

LED State

Indicates

Additional Information

Color

CODE

All

Solid

Digital compressor

controller failure

The installed digital compressor controller can be tested

to verify that it is working properly. In each test, 24VAC

must be supplied to 24VAC and 24COM. For output

test, 24-250VAC must be supplied to L1 and L2.

Input Tests - 1) Thermistor Input - Disconnect thermistor

(T1 & T2); LED should display Code 6.; and 2) Demand

Input - Disconnect unit controller (C1 & C2); LED

should display Code 5 unless a previous alert code was

present.

Output Tests - 1) Contactor Output - while the controller

is powered off (no supply voltage to 24VAC and

24COM), disconnect signal wire from C1 & C2; add

jumper wires from P3 to C2 and from P1 to C1; re-apply

power to 24VAC and 24COM. If functioning normally,

same voltage should be read across M1 and M2 as

across L1 and L2, unless an LED ALERT code is

present.; and 2) Unloader Output - while controller is

modulating the unloader solenoid (whenever the yellow

LED is lit), voltage across U1 and U2 should be the

same as L1 and L2.

All

Flashing

24VAC Supply too low for

operation

7.0 Troubleshooting (cont'd)

7.2 Troubleshooting Compressor Digital Controller (cont'd)