0 maintenance/service procedures - electric, Heat section, Single heating element – Reznor YDSA Operation Manual User Manual

Page 42: Electric heating operation, elements and controls, Service, Location

Form O-Y, PN 273647R1, Page 42

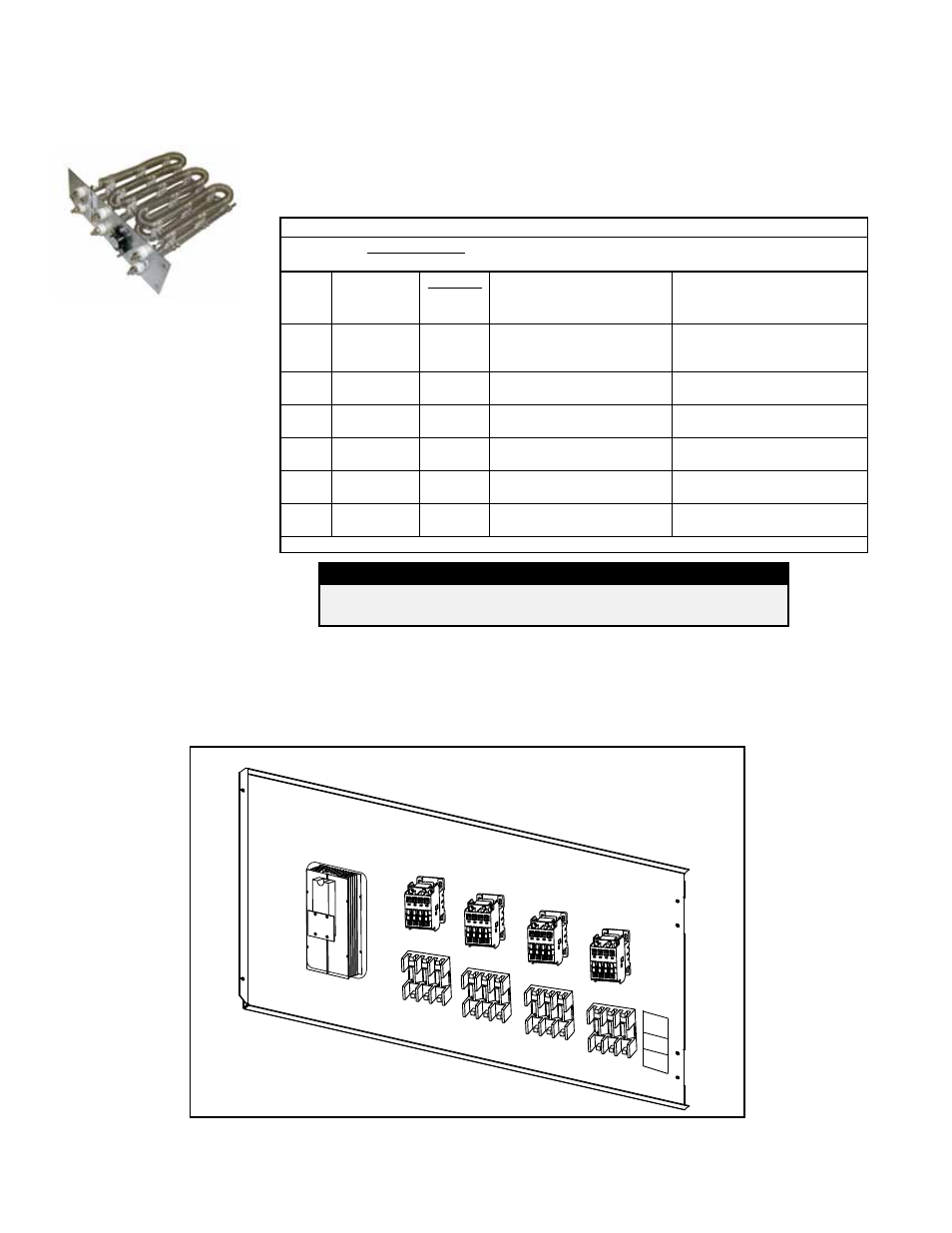

Contactors

Fuse Blocks

SCR Controller

Electric Heat Control Panel

A call for mechanical heat will occur when the discharge air temperature is

5°F(2.8°C) below the active setpoint. When the OAT is below 65°F/18°C (Heating

Lockout SP), the unit enables the mechanical heat to maintain the active setpoint.

The modulated heat output will be set to 30% output and NO8 will be ON. The sys-

tem will remain in this state for 30 seconds. After the initial timer has expired, the unit

will stage as shown in the staging chart and the PID loop will activate. Stages should

be assumed cumulative from the previous stage.

Electric Heat Staging

PI Loop Control:

All Statements Must Be True To Activate or De-Activate.

All stages will have an adjustable min ON and OFF time.

Stage

Outputs

Increase

Inter-Stg

Timer

Activate

De-activate

(No timers to de-activate

except as shown.)

Stg 1

Y4 = 30% for

30 seconds

& NO8 = ON

DAT 5°F (2.8°C) below set-

point (Y4 Modulates, PI Loop)

Y4 < 10% Modulation & DAT

5°F (2.8°C) above setpoint for

10 mins

Stg 2

NO9 = ON

5 min

Y4 > 70% Modulation & DAT

5°F(2.8°C) below setpoint

Y4 < 55% Modulation & DAT

5°F(2.8°C) above setpoint

Stg 3

NO10 = ON

5 min

Y4 > 75% Modulation & DAT

5°F(2.8°C) below setpoint

Y4 < 65% Modulation & DAT

5°F(2.8°C) above setpoint

Stg 4

NO11 = ON

5 min

Y4 > 80% Modulation & DAT

5°F(2.8°C) below setpoint

Y4 < 70% Modulation & DAT

5°F(2.8°C) above setpoint

Stg 5

NO12 = ON

5 min

Y4 > 85% Modulation & DAT

5°F(2.8°C) below setpoint

Y4 < 75% Modulation & DAT

5°F(2.8°C) above setpoint

Stg 6

NO13 = ON

5 min

Y4 > 90% Modulation & DAT

5°F(2.8°C) below setpoint

Y4 < 80% Modulation & DAT

5°F(2.8°C) above setpoint

All parameters are factory level access.

Single Heating

Element

(Each heat

section includes an

assembly of single

elements)

6.0 Maintenance/Service Procedures - Electric Heat Section

Electric Heating

Operation, Elements

and Controls

Service:

Carefully clean all dust and dirt from the heating elements using a brush or steel wool. With a vacuum or air

hose, clean the inside of the cabinet especially the bottom and sides where dirt and dust will accumulate.

If replacement parts are required, check with your distributor and use only factory-authorized replacements.

Location:

See the control location illustration in

FIGURE 1, page 4, and FIGURE 29, shown below for the electric

heat section panel. The distribution blocks, fuses, contactors and optional SCR controller are mounted on the panel.

The quantities and locations of these items depend on the size of the unit.

To access the electric heat elements, remove two screws on the left side of the hinged electric heat control panel.

FIGURE 29 - Electric Heat Control Panel Illustration (NOTE: Danger High Voltage)

DANGER

High voltages are present on the Electric Heat Control Panel

components shown below in FIGURE 26.