5 coils and related components (cont'd), Thermostatic expansion valves, Thermostatic expansion valve – Reznor YDSA Operation Manual User Manual

Page 11: Condensate drain use and maintenance

Form O-Y P/N 273647R1, Page 11

Thermostatic

Expansion Valves

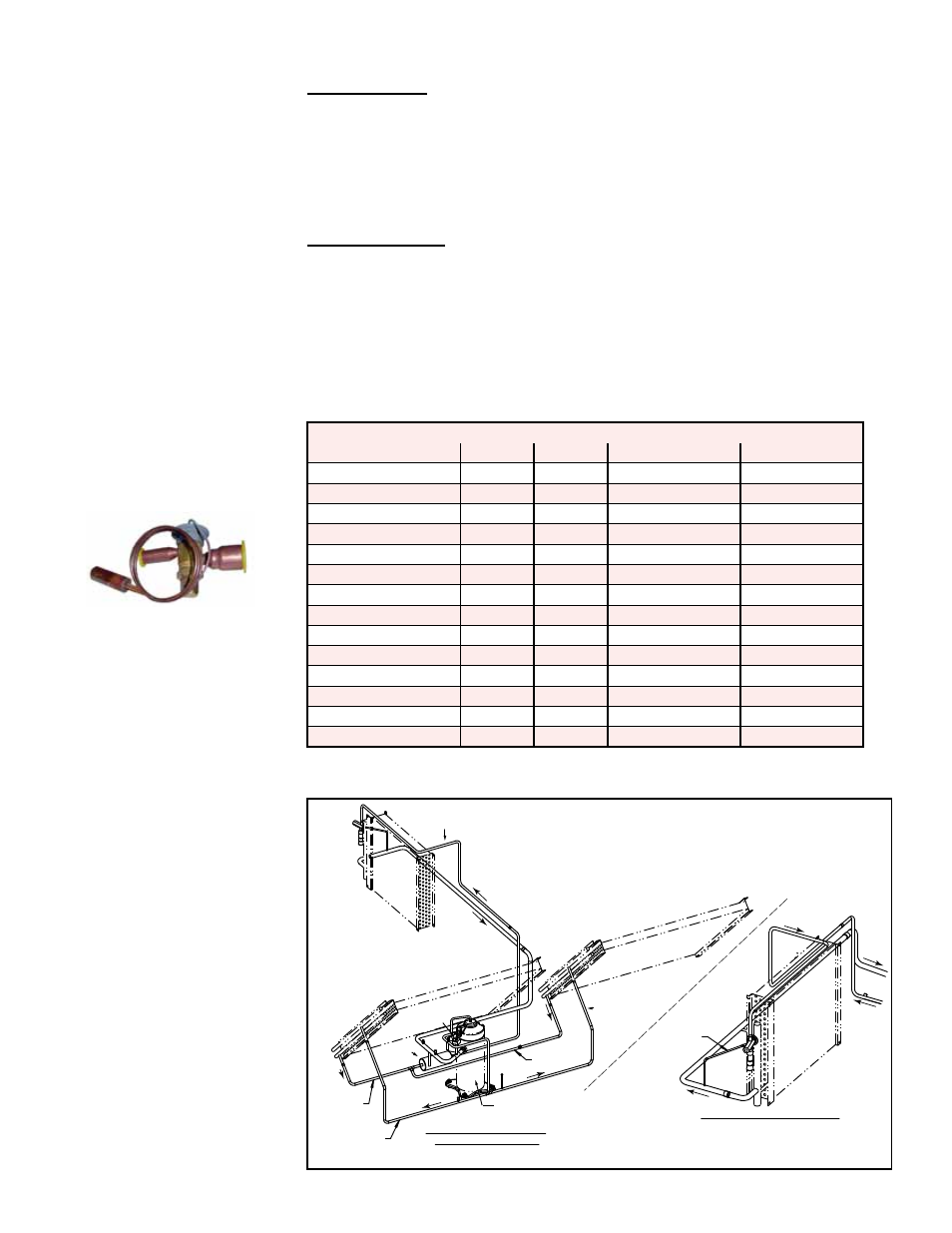

All refrigeration circuits have a thermostatic expansion valve. Thermostatic expansion

valves do not have replaceable parts. If a replacement valve is required, it must be for

R-410A refrigerant and must be sized correctly for the application. All refrigerant ser-

vice should be performed by a service technician qualified in R-410A refrigerant.

Replacement valve P/N's by Model, size, and circuit are listed in the table. Locations

are shown in

FIGURES 8 through 14, shown on pages 11 through 14.

Thermostatic

Expansion Valve

Thermostat Expansion (TXV) Valves by Circuit and P/N

Model / Size

A

B

DH - Low Enthalpy DH - High Enthalpy

YDHA & YDMA 060

234987

--

207303

--

YDHA 090

220556

--

--

207303

YDMA 090

220556

--

207303

--

YDHA & YDMA 120

234987

234987

--

207303

YDSA 120

234960

234960

--

--

YDHA & YDMA 150

220555

220555

--

207303

YDSA 150

220555

220555

--

--

YDHA & YDMA 180

220555

220555

207303

234960

YDSA 180

220555

220555

--

--

YDSA 210

220556

220555

--

--

YDHA & YDMA 210

220556

220556

207303

234960

YDHA & YDMA 240

220556

220556

207303

234960

YDHA & YDMA 300

261175

221175

234960

235729

YDHA & YDMA 360

220558

220558

234960

235729

Model YDMA 060 and 090 (Cabinet 1)

Circuit A-1&2

Condenser Coil

Condenser Coil

Circuit A-1

Circuit A-1

Circuit A-2

View from Compressor and

Evaporator

Compressor

Solenoid

Filter

(Evaporator Coil Side)

Coil

Tube

Valve

Model YDHA 060 and 090 (Cabinet 1)

Circuit

A-2

Circuit

A-1

Circuit A-2

Coil with

Single Circuit

Modulating

Valve

Drier

Evaporator

Equalizer

TXV

Condenser Section Side

View from Cooling Cabinet Door

Refrigerant Circuits - Standard Cooling without Optional Bypass Valve or Reheat

FIGURE 8 - Cooling

Circuit - Models

YDHA and YDMA

Sizes 060 and 090

3.5 Coils and Related Components (cont'd)

Seasonal Usage - At the beginning of the cooling season, inspect and clean the

entire cooling coil cabinet including the condensate drain pan. Thoroughly clean dirt,

algae, grease, and other contaminants. Inspect condensate drain pan, trap, and pip-

ing; fill trap with water to ensure proper operation. During a wintertime shutdown of

the cooling system, it may be desirable to disconnect and remove all water from the

trap and drain to prevent freeze damage. If local building codes permit, trap may be

filled with an antifreeze solution. Or, piping may be designed with freeze plugs or

other freeze protection methods (such as a heat tape).

Year Round Usage - Climates or applications with cooling requirements year round

require more frequent inspections of the cooling coil cabinet and condensate drains.

Depending on climate, freeze protection of the trap may be required during non-

cooling days.

Condensate Drain

Use and Maintenance