5 coils and related components (cont'd), Optional modulating reheat (cont'd) – Reznor YDSA Operation Manual User Manual

Page 14

Form O-Y, PN 273647R1, Page 14

LED

Color

LED

State

Indicates

Green Solid

Power (24VAC present at

power terminals)

Green Flashing Anti-short cycle timer is active

Yellow Solid

Unloader (Solenoid valve

is energized; compressor

capacity is 0.)

Red

Not lit

No abnormal operation alerts

Red

Flashing See Paragraph 7.2 (page 45).

M1

A1 A2

L1 L2

U2

U1

M2

V1 V2

P6

P5 P4

P3 P2

P1

C2

C1

C4

C3

24

VAC

24

COM

T6

T5 T4

T3 T2

T1

Power Light

(Green LED)

Compressor

Modulating

Solenoid Valve

Energized Light

(Yellow LED)

Alarm Light

(Red LED) - See

Paragraph 7.2

shown on page 45.

Compressor Digital

Controller for

Modulating Operation

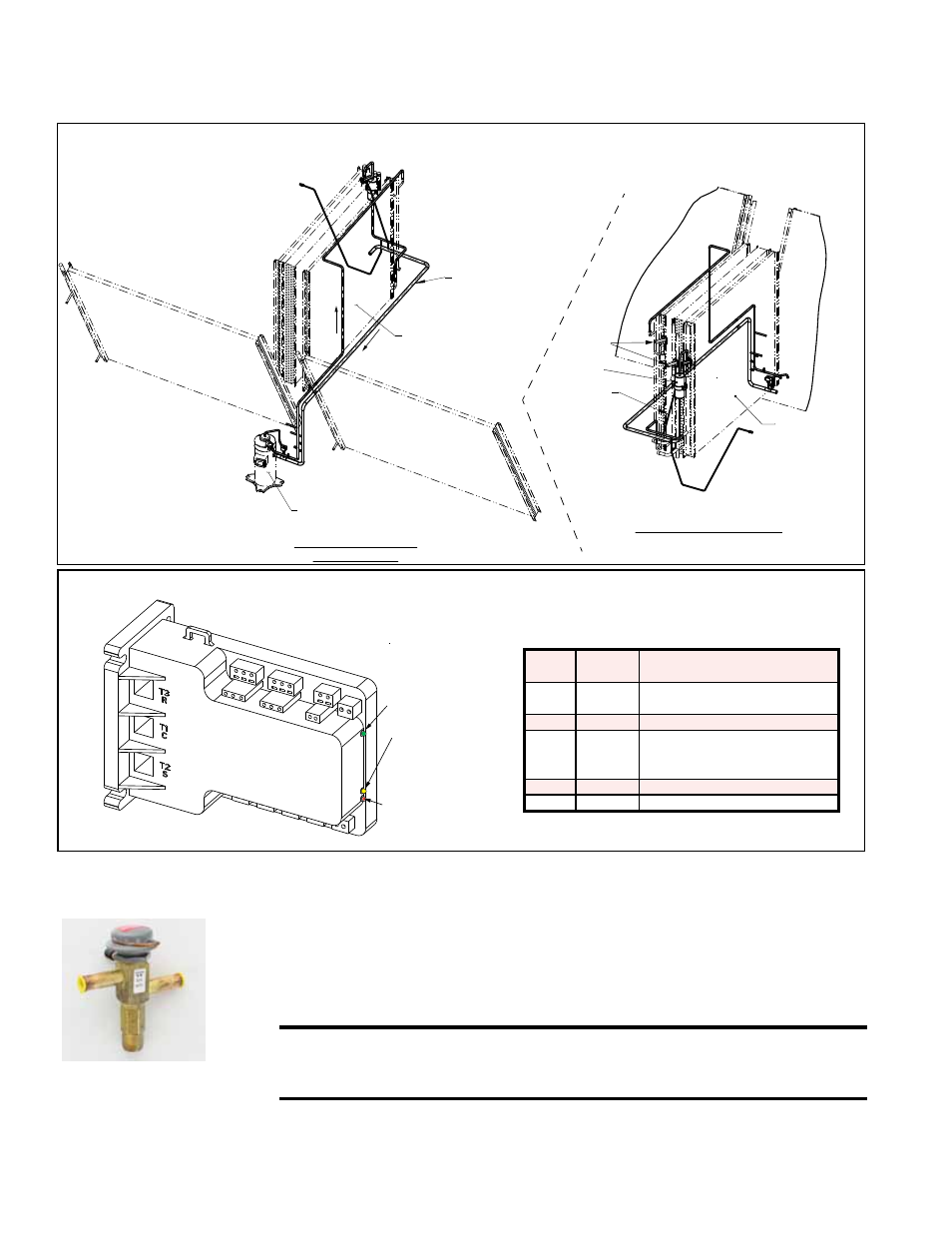

FIGURE 15 - Digital Controller for DH Circuit Compressor, P/N 266067

Function: The hot gas bypass valve allows some of the refrigerant gas from the suc-

tion line to be re-routed directly to the evaporator coil providing for expanded com-

pressor modulation at low outside air temperatures. Hot gas bypass is only on the

non-modulating compressor circuit (Circuit B). See

FIGURE 16 on page 15.

Service: To check the hot gas bypass valve setting, connect a pressure gauge to the

suction line and block the entering air to the evaporator coil. Suction pressure will

drop, and the hot gas bypass valve should begin to open at a approximately 115 psi

and will be fully open at 95 psi. When the valve begins to open it will be hot to the

touch (see caution below).

CAUTION: Touching the operating hot gas bypass valve can cause

a burn. Use caution when checking and adjusting the valve. See

Hazard Levels, page 2.

If a hot gas bypass valve needs to be replaced, use only a factory-authorized

replacement for R-410A refrigerant. All refrigerant service should be done by a

qualified R-410A service technician.

Optional Hot Gas

Bypass Valve

(Option AUC8)

Hot Gas Bypass

Valve

3.0 Maintenance and Service Procedures - Unit & Cooling (cont'd)

3.5 Coils and Related Components (cont'd)

Optional Modulating Reheat (cont'd)

View from Compressor and

Condenser Section

Circuit A & B

Condenser Coil

Circuit B

Modulating

Compressor

Condenser Coil

Circuit

A

Evaporator Coil

with Intertwined

Circuits A & B

View from Cooling Cabinet Door

(Evaporator Coil Side)

Equilizer Tube

Evaporator Coil

Model YDHA 300 & 360 (Cabinet 3)

Model YDMA 300 & 360 (Cabinet 3)

Filter Drier

TXV Valves

FIGURE 14 - Optional

DH Circuit (Option

RPLE Low Enthalpy

Reheat Pump or

Option RPHE High

Enthalpy Reheat Pump