Reznor OH Unit Installation Manual User Manual

Page 9

Form I-OH, PN 120390 R5, Page 9

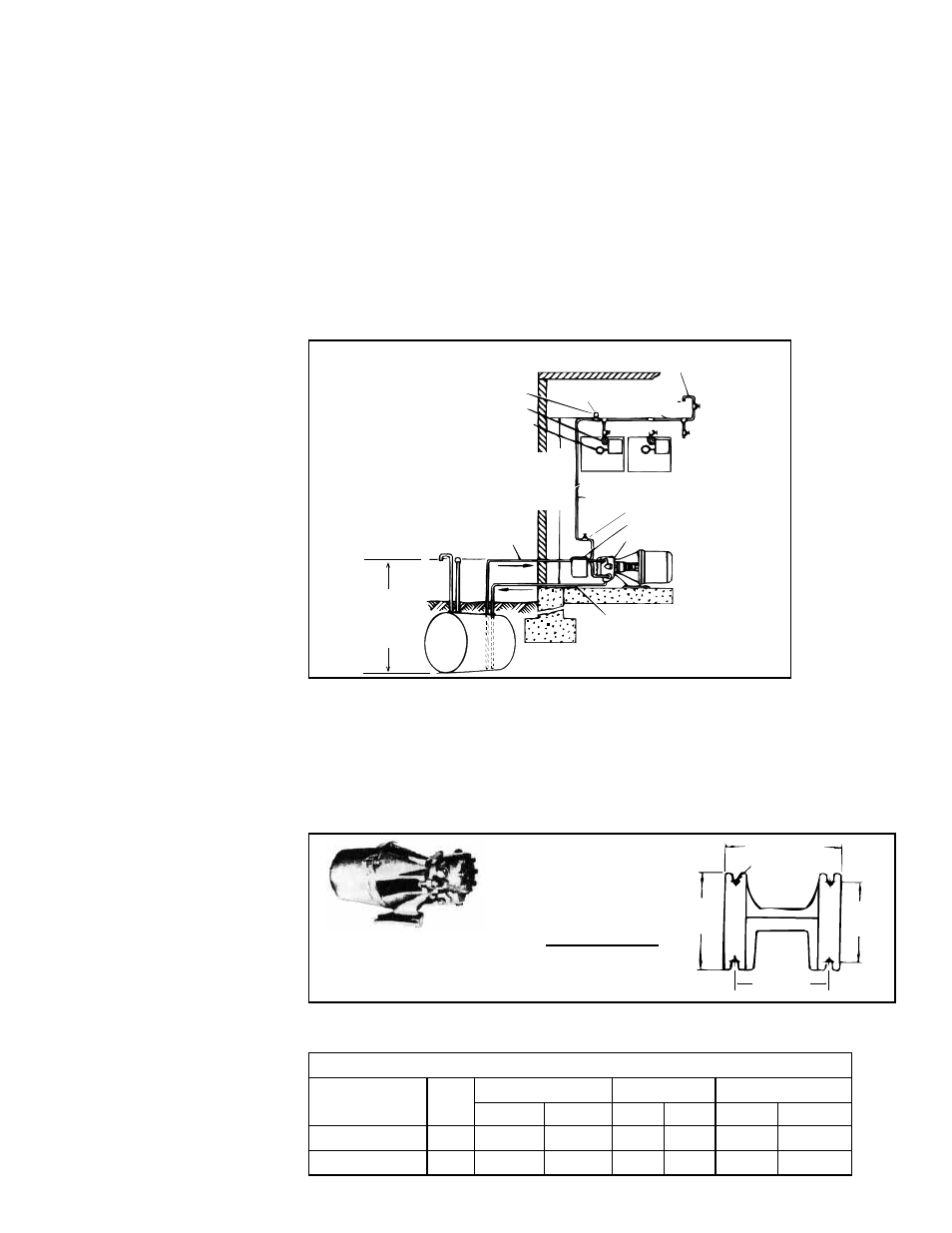

All manifold and feeder lines must run in a horizontal plane at an elevation above the

fuel intakes of the units. Extend feeder lines downward to fuel burner intakes.

6.1.4 Pressurized System

A pressurized system is one in which a boost pump is used to supply fuel oil to a

manifold for which branch lines supply each heater. The end of the manifold is capped,

and the system is operated at a pressure not exceeding 3 psi at the first burner sup-

plied. BTU output in this type of system is determined by boost pump capacity and

the subsequent number of burners that can be supplied adequately by fuel oil. For

example, a 30 GPH booster pump will sustain eighteen 1.65 GPH burners. An optional

solenoid valve is recommended to protect burner pump seal against excessive pres-

sure. Optional pressure switch monitors nozzle pressure and will start booster pump

on pressure fall.

Boost pump operation in a pressurized system may be continuous or may be intermit-

tent when optional pressure switches are used.

6.1.5 Boost Pump Assembly (Option DA1 or DA2)

The boost pump is equipped with a motor and is supplied with a two-stage fuel unit

incorporating a regulator valve and strainer. The valve acts as a check to prevent loss

of oil supply between the boost pump and the burner, thus assuring instantaneous

starts following shutdown periods. Regulator valve also prevents excessive pressures.

Complete assembly with motor is approximately 15" (381mm) long, 7-1/2" (191mm)

high and 6-3/4" (171mm) wide overall.

Manifold Air Bleed -

highest point in line

Compound

Gauge

Maximum Intake Pressure

at Burner is 3 PSI

Pipe Cap

Manifold Line

Furnace

#3 etc

#2

#1

1/2 OD Tubing -

Return Line

Boost Pump

Auxiliary Filter

Shutoff Valve

1/2 OD Tubing

Tank

15 ft

(4.5M)

Maximum

Lift

35 ft

(10.7M)

Maximum

Lift

Pressure Switch (Opt DF1)

Solenoid Valve (Opt DD1)

1/2 OD

Tubing

- Inlet Line

FIGURE 7 -

Pressurized Supply

System (multiple

units)

Boost Pump will run

intermittently. See

Paragraph 6.1.5.

FIGURE 8 - Boost

Pump and Mounting

Bracket

5-7/8 (149mm)

4-7/8

(124mm)

4

(102mm)

4-3/4

(121mm)

R 11/64(4.4mm)

Boost Pump

Bracket

Mounting

Dimensions

(Bottom View)

Boost Pump

30GPH/70GPH

TABLE 7A - Maximum Horizontal Length from Boost Pump to Burner(s)

Boost Pump

GPH

1/2" OD Tubing

1/2" Pipe

3/4" Pipe

ft

M

ft

M

ft

M

Option DA1

30

175

53.3

300

91.4

1800

548.6

Option DA2

70

50

15.2

100

30.5

600

182.9

Boost Pump Capacities

Maximum Height from Boost Pump to Burner -- 35 feet (10.7M).