Maintenance and service (cont'd), 2 maintenance procedures (cont'd) – Reznor OH Unit Installation Manual User Manual

Page 24

Form I-OH, PN 120390 R5, Page 24

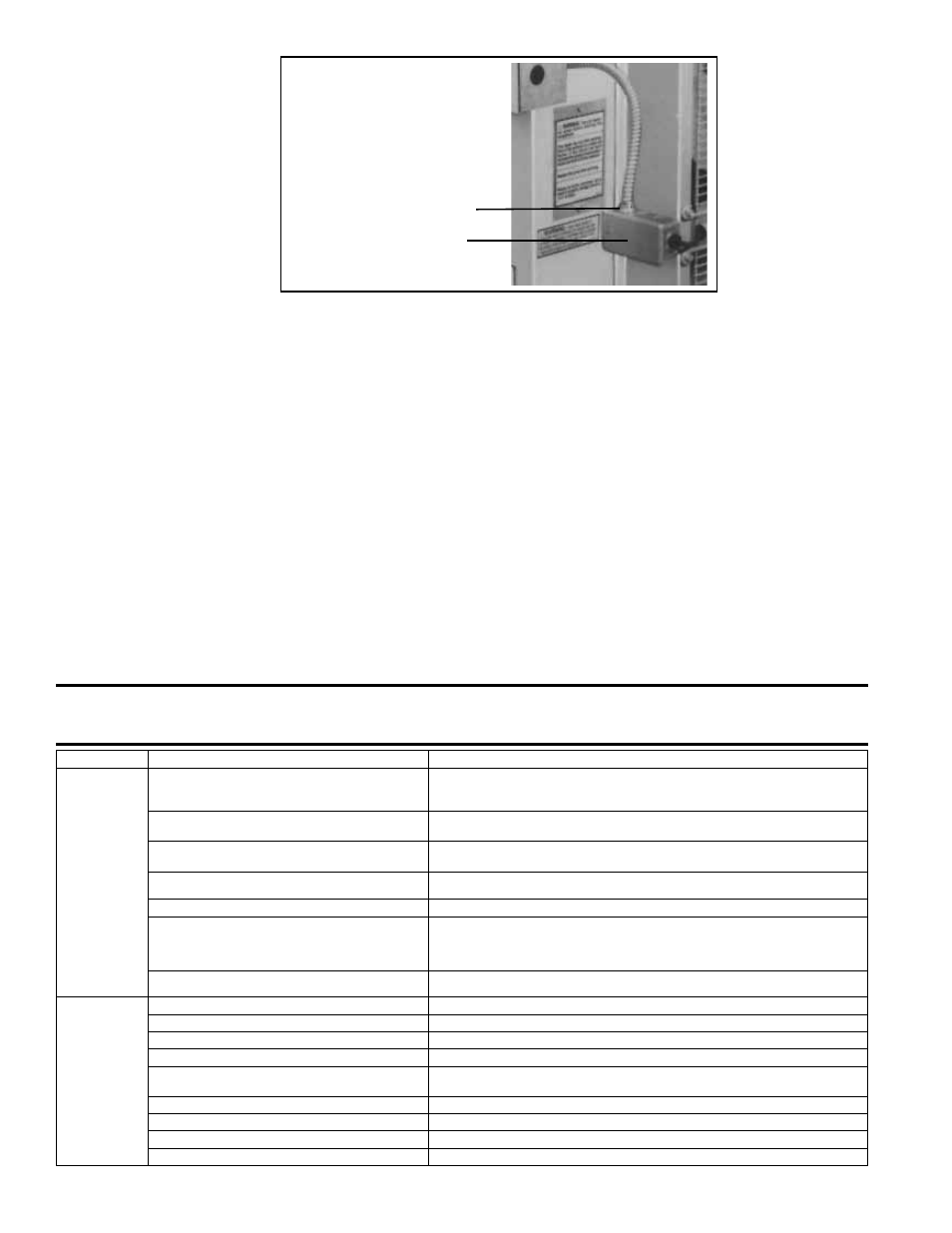

Junction

Box

Flexible Conduit

Connection

FIGURE 29 - Fan

Junction Box Located

on Rear of Heater.

Clean the fan. Use a brush and a shop vac, being careful not to bend or damage the

fan blades. Use a shop vac to remove accumulated dirt from the motor.

Reattach the fan and the discharge louvers. Connect the flexible conduit and wiring.

Check operation.

Cleaning ensures maximum efficiency and eliminates the possibility of the heater

cycling on the limit switch from lack of air flow.

This oil-fired heater has been designed and manufactured to provide trouble free oper-

ation. However, as with any type of mechanical equipment, it can fail. For your safety,

if there is a problem, contact a qualified service person.

To diagnose malfunctions properly, the following testing equipment is required:

√ An electrical test meter that can measure volts, ohms, and amps

√ An ignition transformer tester

√ A combustion analyzer kit to measure oxygen or carbon dioxide, smoke, stack

temperature, draft, and system efficiency

√ A pressure/vacuum gauge with a scale of 0-200 psig and 0-30" hg.

Before test firing any heater, check the combustion chamber for an excessive accumu-

lation of unburned oil and restore to a safe condition before firing.

9.3 Troubleshooting

WARNING: Do not attempt to start the burner when excess oil has accumulated,

when the furnace is full of vapor, or when the combustion chamber is very hot.

9. Maintenance

and Service

(cont'd)

9.2 Maintenance

Procedures

(cont'd)

Symptom

Cause

Action

Burner motor

does not start

1. Incomplete electrical circuit

1. Measure the line voltage at the primary control input connection. Should have nominal 120 volts.

(Lower than 105 volts may cause operating problems.) If there is no reading, check disconnect

switch, fuses, and thermostat connections.

2. Primary control activated. Relay "on safety" position will lock

out burner operation.

2. *Follow the instructions starting on page 25 to determine the cause of the lockout. Correct the

malfunction.

3. Inadequate voltage between motor/primary lead and neutral

connection.

3. Line voltage must be within 10% of the voltage specified on the motor rating plate.

4. Motor hums but shaft does not rotate.

4. Start switch may be defective. With the power turned off, rotate the blower wheel by hand. If it

turns freely, replace the motor.

5. Motor bearings frozen.

5. Free shaft and lubricate or replace motor.

6. Overload protection activated

6. Allow the motor to cool. Start the motor and measure the current draw. This reading should not

exceed the rating plate specifications under load conditions by more than 10%. Excessive amp draw

usually means an overload condition, defective start switch or shorted windings. Replace motor if

necessary. (It is difficult and not usually cost effective to attempt to rebuild the motor.)

7. Blocked vent switch is open (CSA unit only)

7. Determine and correct the reason the blocked vent switch is activated. Reset the switch.

Burner motor op-

erates but no fuel

is delivered at the

nozzle.

1. Oil level below intake in tank

1. Fill and bleed air from fuel line.

2. Clogged strainer

2. Remove and clean strainer

3. Restricted fuel supply line

3. Open all valves in supply line. Replace any kinked tubing.

4. Clogged nozzle

4. Replace nozzle.

5. Air leak in the supply line

5. Tighten all fittings in the line. Tighten unused intake port plug in the fuel pump. If there are valves

in the line, be sure the valve stems are packed solid and tightened securely.

6. Two pipe system that becomes air bound.

6. Insert bypass plug if not in place. Re-start unit and prime pump.

7. Motor operates but does not drive the pump shaft.

7. Check the coupling for slippage due to stripped end caps. Replace coupling.

8. Frozen oil pump shaft

8. Replace oil pump.

9. Suction line oil filter cartridge dirty

9. Replace cartridge.