Reznor OH Unit Installation Manual User Manual

Page 25

Form I-OH, PN 120390 R5, Page 25

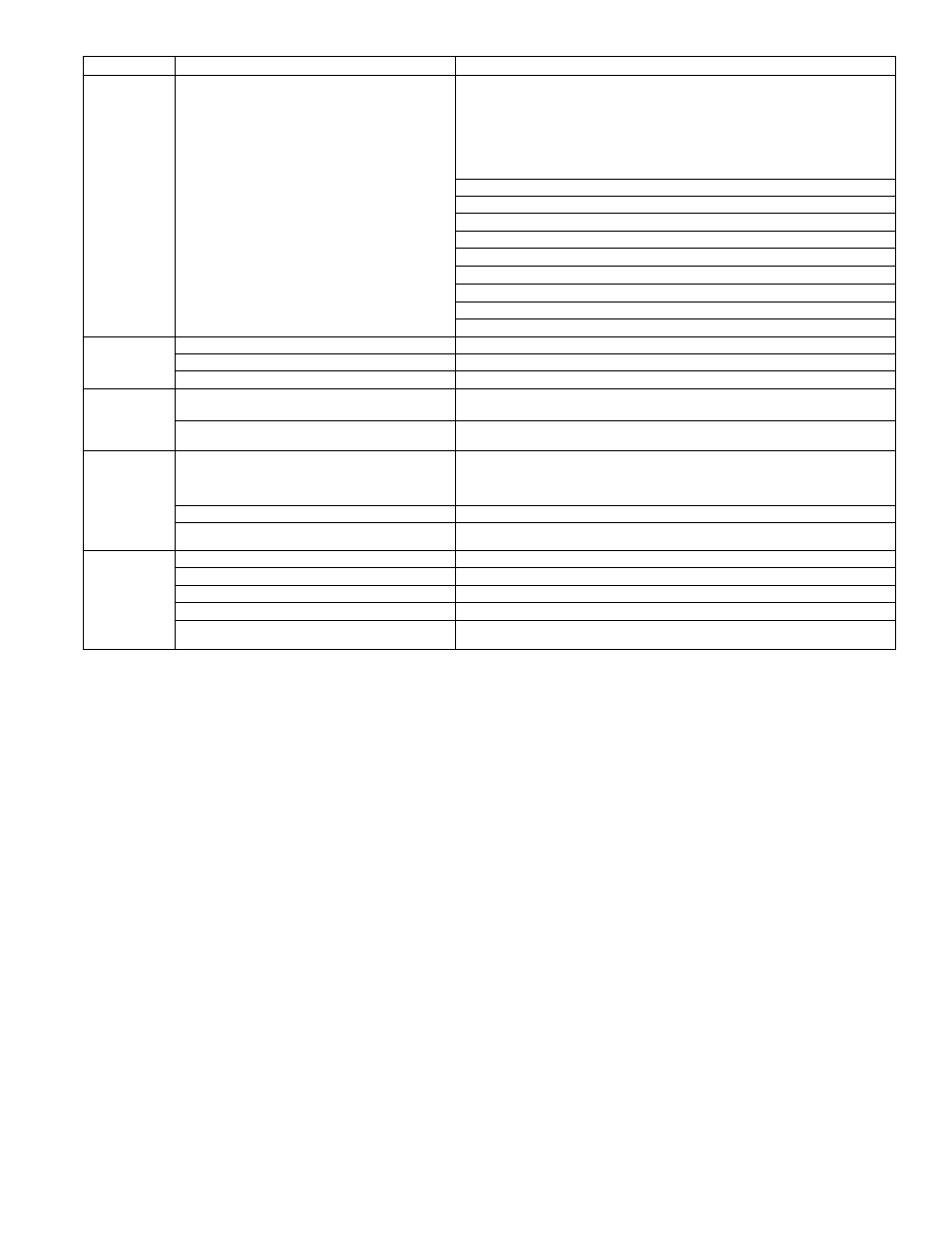

Symptom (cont'd) Cause (cont'd)

Action (cont'd)

Burner motor

operates and

delivers oil, but

there is no flame.

1. No spark

1. Measure voltage between transformer/primary lead and neutral connection. Check transformer,

insulators and electrodes. The secondary terminals of a good transformer deliver 5000 volts arc to

ground, for a total of 10,000 volts between the terminals. Measure this with transformer tester or

use a well-insulated screwdriver to draw an arc across the two springs. This should be at least 3/4"

in length. Check each secondary output terminal by drawing a strong arc between the spring and

the base. If arc is erratic, weak, or unbalanced between the two terminals, replace the transformer.

Replace electrodes when the tips become worn or eroded. Replace any insulators that are

questionable. Transformer failures and ignition problems can be caused by the following:

a) Excessive gap on the ignition electrodes. Gap should be 1/8".

b) High ambient temperatures

c) High humidity

d) Carbon residue on the porcelain bushings

e) Low input line voltage

f) Arcing between the ignition electrodes and the transformer springs. They must have good contact.

g) Carbon residue, moisture, crazing or pin holes on the insulators.

h) Improper positioning of nozzle in relation to the radius of the endcone.

I) Carbon residue on electrode parts.

Burner starts but

flame blows away

from nozzle.

1. Excessive combustion air

1. Adjust air band and air shutter. See Paragraph 8.2.

2. Excessive draft

2. Adjust draft regulator for .01" w.c. overfire draft.

3. Poor atomization of oil

3. Adjust fuel feed pressure; change nozzle.

Poor light off and

shutdown.

1. Air pocket between pressure shutdown valve and nozzle

1. Tighten unused intake port plug in the fuel pump. Run burner stopping and starting occasionally

until pulsation, smoke, and after flame disappear.

2. Insufficient draft over fire

2. Check venting for excessive length, insufficient pitch upward to chimney, too many elbows,

obstructed chimney, or too small chimney. Check for too high combustion air setting.

Noise

1. Noisy motor

1. Check for alignment of the shaft with the coupling. Tighten or slightly loosen the motor-to-burner-

housing bolts in an alternate sequence, which may solve the problem. Check for a loose blower

wheel, excessive radial shaft play and for loose start switch parts. Check if thermocouple is laying

on the blower wheel.

2. Clogged strainer

2. Remove and clean strainer.

3. Burner vibrations transmitted through rigid electrical conduit

or oil lines.

3. Tubing or conduit should not be fastened to studs, or beams so securely that vibration can be

transmitted to floor or roof.

Oil Odors

1. Oil leaks

1. Check fittings and valve seals.

2. Poor burner shutoff

2. Check fuel shutoff valve and time delay relay.

3. Smoky flame

3. Check nozzle spray, air gap, and air shutter setting.

4. Oil carbonization on the burner endcone

4. Check nozzle location relative to inside radius of endcone.

5. Downdraft causing smoke to enter the building through the

barometric draft regulator.

5. Increase draft by extending chimney height, or adding a ventilating cap or draft inducer.

*

Procedure for

determining the

malfunction that

caused the primary

control to activate

(Chart Symptom 2;

Cause and Action 2 )

1. Disconnect the nozzle line connector tube and re-position it so that oil goes into a

container. Tighten the flare nut at the pump discharge fitting.

2. Reset the primary control safety switch and immediately be alert to watch and lis-

ten for the following:

a) Contact action of the primary control relay. Relay should pull in promptly without

arcing erratically or chattering. If relay does not function properly, see Step 4.

b) Quality of oil delivery. Oil stream should be immediate, clear and steady. A white,

frothy oil delivery indicates air in the supply system. No oil delivery indicates a

severe restriction.

c) Ignition Arc - When the ignition activates, you should hear a buzz. If the ignition

does not activate, check the transformer and electrodes.

d) Motor Operating Characteristics - The motor should start quickly and smoothly.

You can hear the RPM change and a click as the centrifugal switch disconnects

the start (auxiliary) winding.

3. If the malfunction has not been revealed, reconnect the nozzle line fittings and

prepare for a fire test. Be sure to check the combustion chamber and remove any

accumulation of unburned oil.

Reset the primary control, if necessary, and observe the overall performance with

concentration on the light-off. Run several cycles. Observe the flame quality using

a flame mirror, if possible. Flame base should be stable and close to the com-

bustion head. Flame should be centered, uniform in shape and relatively quiet in

operation. Check the heat and combustion chamber for carbon or impingements.,

indicating a defective or partially clogged nozzle.

4. If the problem is not apparent, check the primary control system.

Measure the electrical voltage at the primary input (usually black) and neutral lead

(usually white) connections.

Jumper the thermostat (TT terminals) or otherwise energize the primary control.