Reznor OH Unit Installation Manual User Manual

Page 23

Form I-OH, PN 120390 R5, Page 23

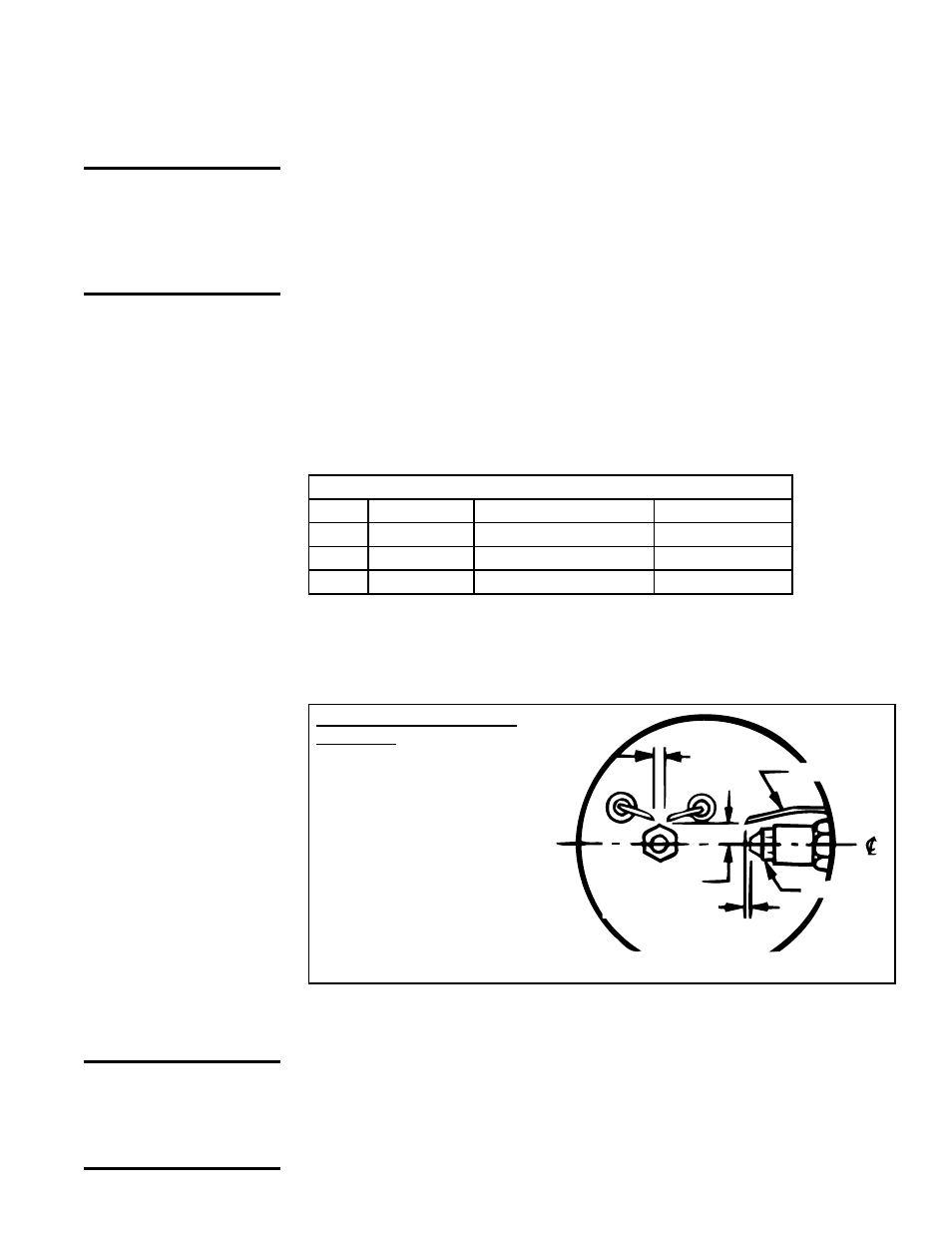

Gap -

1/8 (3.1mm)

Electrode

Nozzle

0 to 1/16

(1.6mm) ahead

7/16 (11mm) above

ELECTRODE

ADJUSTMENTS

FIGURE 28 -

Electrode Adjustment

(Front and Side

Views)

Servicing/Replacing Spark

Electrodes - Remove any

carbon formation on the spark

electrodes. Check the elec-

trodes for deterioration and the

insulators for cracks or dam-

age. Replace the electrode

assemblies if any damage or

deterioration exists.

After service or replacement,

check the position of the elec-

trodes. Adjust the electrode

location precisely as illus-

trated.

4) When cleaning/service is completed, place the mounting plate gasket (NOTE: If

gasket is damaged it should be replaced.) on the studs. Align the burner mounting

plate with the bolts and slide the tube into the heater. Attach the mounting plate

with the three nuts.

5) Reconnect the yellow wires to the ignition controller.

9.2.3 Removing Fuel Line Assembly to Service Nozzle and Spark

Electrodes

In order to service the oil nozzle and spark electrodes, it is necessary to remove the

fuel line assembly.

Instructions for Removing Fuel Line Assembly

1. Loosen the connection nut (where line connects to the burner) one or two turns.

2. Disconnect the fuel connection assembly by loosening the 5/16" inverted flare fit-

ting. Pull the fuel connection assembly clear of the burner housing.

3. Remove the two screws retaining the spark transformer cover to the burner hous-

ing. Lift the hinged transformer to its open position.

4. The fuel line assembly may now be removed. Pull the assembly up slightly and

toward the rear of the burner housing.

Oil Nozzle Replacement -- With the fuel line assembly removed, use a box wrench to

remove the oil nozzle. Replace the oil nozzle with a factory-authorized replacement.

See table below for nozzle selection.

Do not substitute nozzles.

TABLE 12 - Replacement Burner Nozzle and Pump Pressure

Size

Reznor P/N

Delavan Nozzle Type

Pump Pressure

95

32437

0.85, 80

°

, B

100 lbs

140*

146815

1.25, 70

°

, B

100 lbs

190*

146816

1.35, 70

°

, B

150 lbs

*These replacement nozzle sizes apply to heaters manufactured beginning 6/96.

Always check the nozzle for size and replace with an identical nozzle.

When replacing the nozzle, inspect electrodes and check electrode adjustment before

reassembling the heater.

9.2.4 Cleaning Exterior Surfaces of the Combustion Chamber/Heat

Exchanger and Air Moving Device

To gain access to the front of the combustion chamber/heat exchanger assembly,

remove the discharge louvers. To access the rear side, remove the fan assembly. To

remove the fan, disconnect the wiring in the fan junction box and the flexible conduit.

Refer to

FIGURE 29.

Use a stiff brush and a shop vac to clean the accumulated dust and dirt from the exte-

rior surface of the combustion chamber and the heat exchanger.

WARNING: Turn off

the electric power

before cleaning the

heater.

WARNING: Turn

off electric power

before inspecting

or cleaning this

heater.