Maintenance and service (cont'd), 3 troubleshooting (cont'd) – Reznor OH Unit Installation Manual User Manual

Page 26

Form I-OH, PN 120390 R5, Page 26

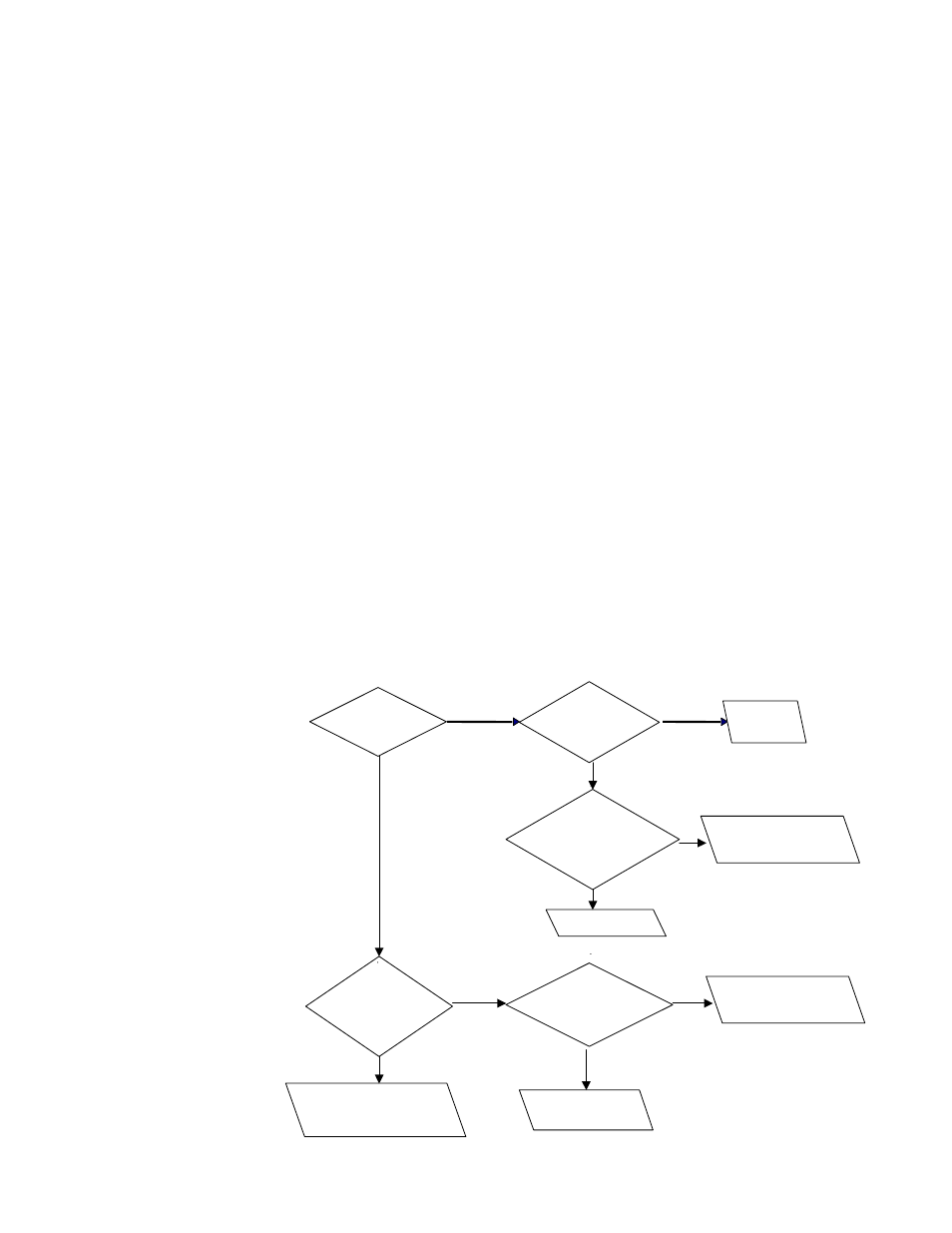

Does the fan

operate?

Are the heat

exchanger surfaces

and/or the fan blades

covered with

dirt?

Clean the heat

exchanger and fan.

See Paragraphs 9.2.1 and .4.

Remove ducts or

deflector from heater.

Check for 115

volts across fan leads.

Is voltage

read?

Replace fan

motor.

Check for 115 volts

across Terminals 1 & 2.

Is voltage

read?

Replace fan and limit

controls assembly.

See

FIGURE 18, page 16.

Check wiring.

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

Have ducts or

air deflectors

been added ?

Replace fan and limit

controls assembly.

See

FIGURE 18, page 16.

** High temperature limit

cycles when internal tem-

perature exceeds nonad-

justable limit setpoint (Size

95, 145°F; Sizes 140 and

190, 160°F). Cause must

be found and corrected for

heater to function safely/

properly.

9.3.2 Troubleshooting

Guide - High

Temperature Limit

Cycles **

9.3.1 Troubleshooting

the Oil Burner

(cont'd)

9. Maintenance

and Service

(cont'd)

9.3 Troubleshooting

(cont'd)

The control relay should pull in. If not, make sure that the wiring connections are

secure. If wiring connections are secure, check that the cad cell which controls the

safety lockout timing on ignition is not seeing too much stray light. Check the cad

cell by starting the burner and disconnecting both cad cell leads from the control

FF terminals. Jumper the FF terminals to keep the burner operating. Measure the

ohms resistance across the cad cell leads as it views the flame. This should be

1600 ohms or less. A preferred reading is 300-1000 ohms. Next, with the meter

still connected to the cad cell leads, turn the burner off. The dark condition should

give a reading of 20,000 ohms or infinity. If the reading is lower, let the refractory

cool down or look for stray light that might be entering the burner through the air

inlet, or around the transformer baseplate. If the cad cell is not performing within

these guidelines, replace it. If the wiring connections are secure and the safety

lock timing and cad cell are functioning properly, replace the primary control.

If the primary control relay pulls in and then locks out again quickly, check the

safety lockout timing. The safety lockout timing can be checked by removing one

of the F (cad cell) leads from the control. Count the seconds until the control locks

out. The time should be close to the rating plate specification found on the control

body.

If the primary control relay pulls in erratically and chatters, check the wiring con-

nections and verify that the heat anticipator setting of the thermostat matches the

24 volt current draw. Erratic operation can sometimes be traced to improper antici-

pator settings of the primary control. These settings are typically .2 or .4 amps

(printed on the side of the control). Measure this value by connecting your multi-

tester in series with one of the TT lead and reading the value of the appropriate

milliampere scale. If the wiring connections are secure and the anticipator settings

are correct, replace the primary control.

If the primary control relay pulls in, but the motor fails to start, measure the voltage

between the neutral lead and the primary control lead for the motor. A severe volt-

age drop here would indicate that the relay switch contacts are defective. Replace

the primary control.