Commissioning and startup (cont'd) – Reznor OH Unit Installation Manual User Manual

Page 18

Form I-OH, PN 120390 R5, Page 18

of more than ten pounds per square inch on the tank. This test shall be maintained

for at least 30 minutes or for sufficient time to complete a visual inspection of all

joints and connections. Instead of a pressure test to check piping, suction lines

may be used under a vacuum of not less than 20 inches of mercury maintained for

at least 30 minutes.

□

Check vents. Be sure that vent pipe and chimney meet requirements shown

in Paragraph 6.2. An approved draft regulator is required.

In order to measure

the draft in the stack after firing, drill a 5/16" hole in the flue pipe halfway

between the heater and the draft regulator for insertion of the draft gauge.

□

Check electrode adjustment. See instructions in Paragraph 9.2.3. Turn off the

electric power before making check.

□

Check oil delivery. For an accurate check on the oil delivery, remove the burner

assembly and connect it outside the firebox. Disconnect high tension lead. Start

the burner, collect the oil flow for one minute and measure it in a container marked

in cubic centimeters. (Some safety controls may trip when operated for one min-

ute. If this occurs, collect the flow from the nozzle for 30 seconds, measure the

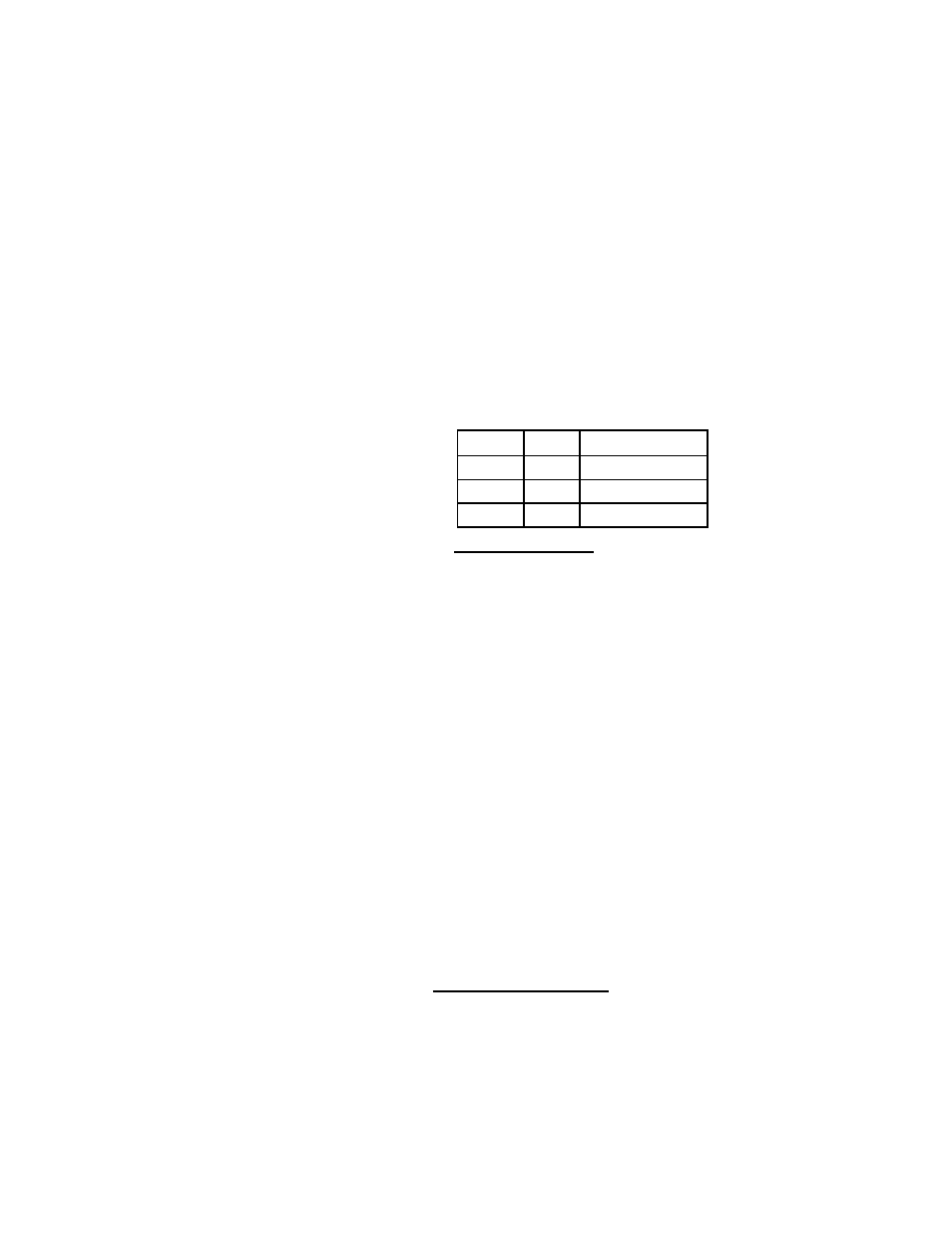

cubic centimeters, multiply by two and check with the chart.) Listed in the table is

the required flow in cubic centimeters (cc) per minute to obtain the output in gal-

lons per hour.

8.2 Check-Test-

Start (Operating

Procedure)

□

Priming the heater -- single pipe system. The oil supply line to the heater must

be full of oil and free of air for proper heater operation. Follow the steps below to

fill the oil line.

Note: Priming the oil line could take up to 30 minutes depending on

the size of heater and the length of the supply line.

1. Be sure that the oil tank is filled to a level at least 6" (152mm) above the foot valve.

2. Set the thermostat to its lowest setting.

3. Connect a piece of rubber tubing to the air bleed valve on the burner pump (See

FIG-

URE 19) and place the other end into an open container (no smaller than a pint).

4. Turn off the electrical power at the switch on the heater electrical box. See

FIGURE

20.

5. Using a 3/8" wrench, loosen the air bleed valve two or three turns.

6. Set the thermostat above room temperature.

7. Turn the electric power on. Burner pump will operate.

8. Oil will run into the container when the air has been bled from the line. (While operat-

ing under these conditions, the heater will not light because the pressure valve in the

pump will not open.) If the primary control activates to shut down the pump before the

line is bled, push the reset button. See

FIGURE 20. It may be necessary to push the

reset button several times while bleeding off air. Wait three to four minutes between

pushes of the reset button to allow the internal bimetal strip to cool down. The pump

will run for 45 seconds each time.

9. After all of the air is bled from the line, close the bleeder valve. Turn the main power

off.

□

Priming the Unit - two-pipe supply system. Install a pressure gauge and turn

the burner on. The system will vent itself through the return line. Flame will appear

as soon as the air has been eliminated.

□

Check and adjust nozzle pressure.

1) Install a pressure gauge (125 psig minimum) into the pressure gauge port on the

burner pump. (See

FIGURE 19.)

2) The air shutter was preset at the factory. Verify the air shutter setting on the burner

with the chart in

FIGURE 21. All other controls should be in normal position.

3) Turn off the electrical power.

4) Set the thermostat to above room temperature.

8. Commissioning

and Startup

(cont'd)

8.1 Checklist Prior

to Startup

(cont'd)

Size

GPH

CC per Minute

95

0.85

54.0

140

1.25

78.5

190

1.35

85.0

TABLE 10 -

Check Oil

Flow Rate