Maintenance and service, Commissioning and startup (cont'd), 1 maintenance requirements – Reznor OH Unit Installation Manual User Manual

Page 20: 2 maintenance procedures, 2 check-test- start (operating procedure cont'd)

Form I-OH, PN 120390 R5, Page 20

9. Maintenance

and Service

The service and troubleshooting information in this section is designed to assist a

qualified service person.

9.1 Maintenance Requirements

Like all quality equipment, this oil-fired unit heater will operate with a minimum of main-

tenance. However, to ensure long life and satisfactory performance, the following ser-

vice regimen is recommended.

Heaters should be inspected once every four months where the equipment is operating

under normal conditions. If the heater is located in an area where an unusual amount

of dust or soot or other impurities are contained in the air, more frequent inspection

is recommended. Check the motor for cleanliness. Remove dirt and grease from the

outside of the motor, and especially around the shaft. Keep air openings free of grease

and dirt. The heat exchanger should be checked at least once a year and more often

in areas where the air is heavily dust laden.

9.2 Maintenance

Procedures

9.2.1 Cleaning Combustion Chamber, Heat Exchanger, and Flue

Pipe

WARNING: Turn off electric power before inspecting or

cleaning this heater.

Instructions for removing soot from the combustion chamber/heat

exchanger

1. On the burner end of the heater, locate the small exhaust door panel underneath

the burner tray. See

FIGURE 22. On Canadian Models, there is a screw (not shown

8.2 Check-Test-

Start (Operating

Procedure

cont'd)

8. Commissioning

and Startup

(cont'd)

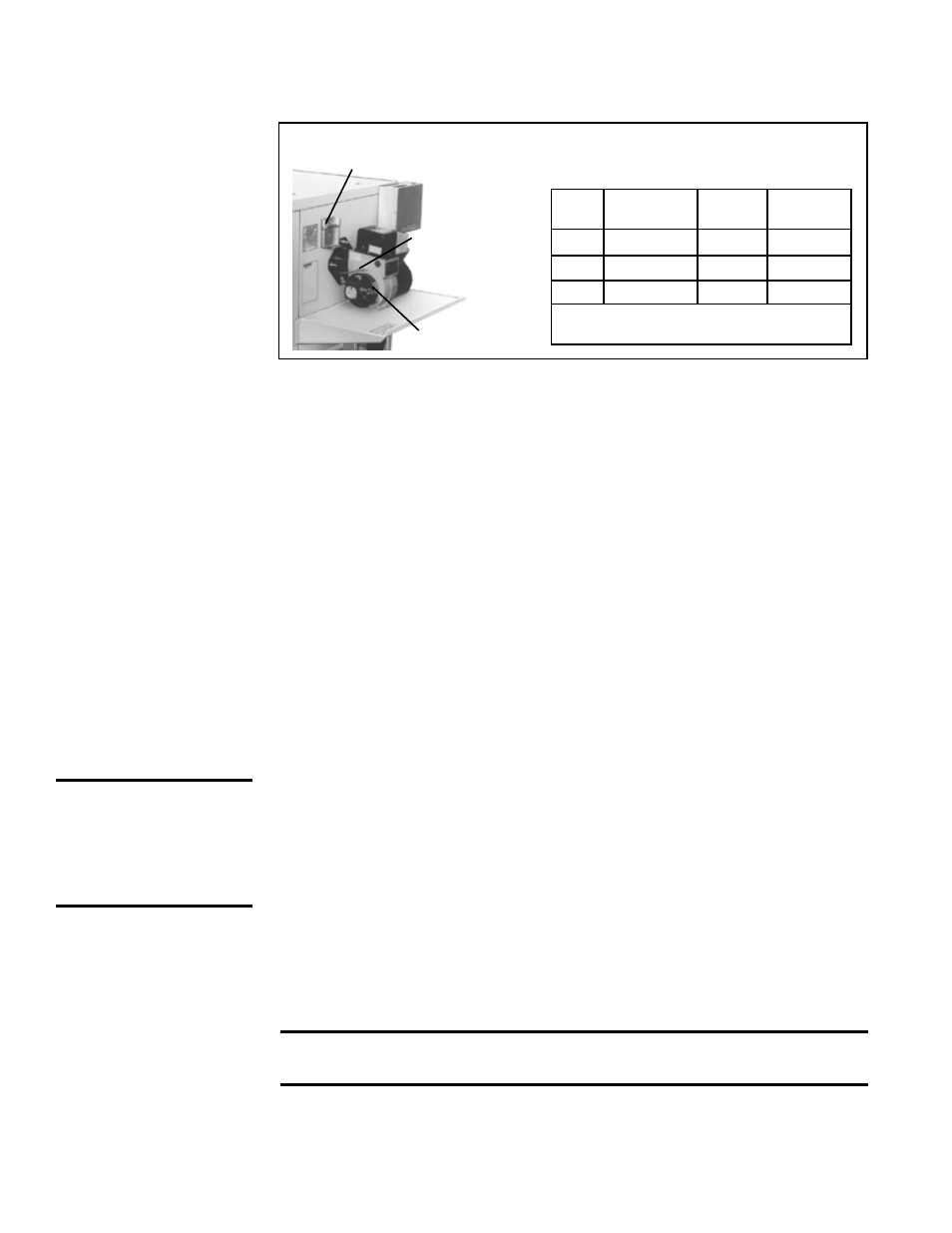

Air Band

Observation Door

Air Shutter

FIGURE 21 - Combustion Air Band and Air Shutter Settings

Size

Air

Shutter

Air

Band

CO2

Range

95

#6

#0

9-11%

140

#6

#0

10-12%

190*

#7-1/2

#0

11-13%

*Size 190 manufactured before 6/96 had

same settings as Size 140.

TABLE 11 - Settings

these settings will result in a CO

2

level shown in the tabled ranges. However, cer-

tain field conditions may require a change. In order to determine if the air setting

needs to be adjusted, a smoke tester and CO

2

analyzer are required.

Air Adjustment Procedure:

1) Service and clean the burner, combustion chamber, and heat exchanger if

necessary.

2) Operate the unit for at least 10 minutes.

3) Adjust the overfire draft to read between -0.01" to -0.02" w.c. Draft readings in the

breaching will be higher depending on the flue passages of the heater. The more

restrictive and lengthy the flue, the higher the draft necessary to obtain accepted

overfire conditions.

4) Follow the instructions of the manufacturer of the smoke tester and take a smoke

reading. Adjust the combustion air to obtain a preliminary reading of about a No. 3

smoke spot. Then readjust the air until a reading between No. 0 and No. 1 (trace

smoke) is achieved. Do not open the air adjustment more than absolutely neces-

sary to obtain a trace or No. 0 smoke spot.

5) Follow the instructions of the manufacturer of the CO

2

gas analyzer and take a

CO

2

sample. Open the air shutter until the CO

2

level lowers by 1%. The CO

2

read-

ing should fall within the range specified in the table shown in

FIGURE 21. Your

burner is now set for optimum but stable efficiency.

WARNING: Turn

off electric power

before inspecting

or cleaning this

heater.