Channel radio setup – Great Planes Giant Aeromaster Kit - GPMA0502 User Manual

Page 45

The aileron connecting pushrods are assembled following

the same method used to assemble the N-struts If you

installed aileron servos in the top and bottom wing proceed

to the Set the Control Throws section

D 1 Cut the two 5/8" x 12" hardwood aileron connection

pushrods to the shape shown on the fuselage plan Use a

sanding bar loaded with 150-grit sandpaper to round the

tips to the desired shape The struts can be covered with

MonoKote film covering or painted with a fuelproof paint

such as LustreKote spray paint.

D 2 Use a 5/64" drill bit to drill a hole 1/2" deep, centered

in the notch, at both ends of the connecting pushrod.

D 3. Thread two 4-40 nuts close to the head of two of the

4-40 x 1" machine screws Mix a small amount of

30-minute epoxy and apply a small amount to the last 1/2"

of threads on the machine screws Then thread the

machine screw halfway into the end of the connecting

pushrod Install only the two machine screws with the nuts

installed.

D 4 After the epoxy has cured, thread the nut against the

connecting pushrods and use a cut-off wheel or hack saw

to cut off the head of the machine screw Unscrew the nut

from the machine screw The nut will clean up the threads

as it is removed.

D 5 After all the nuts have been removed, thread the nuts

onto the remaining two 4 40 x 1" machine screws and

install them in the remaining ends of the struts following the

same procedure as before.

D 6. Place the connecting pushrods over the plan to

determine which end will go at the top Thread a 4-40 nut

on that end Thread a 4-40 metal clevis onto both ends of

the two connecting pushrods. The nut will be used later to

lock the clevis in position.

D 7 Attach the connecting pushrods to the ailerons on

both wings Adjust the aileron connecting pushrods so

that the ailerons are in the same position on the top and

bottom wing.

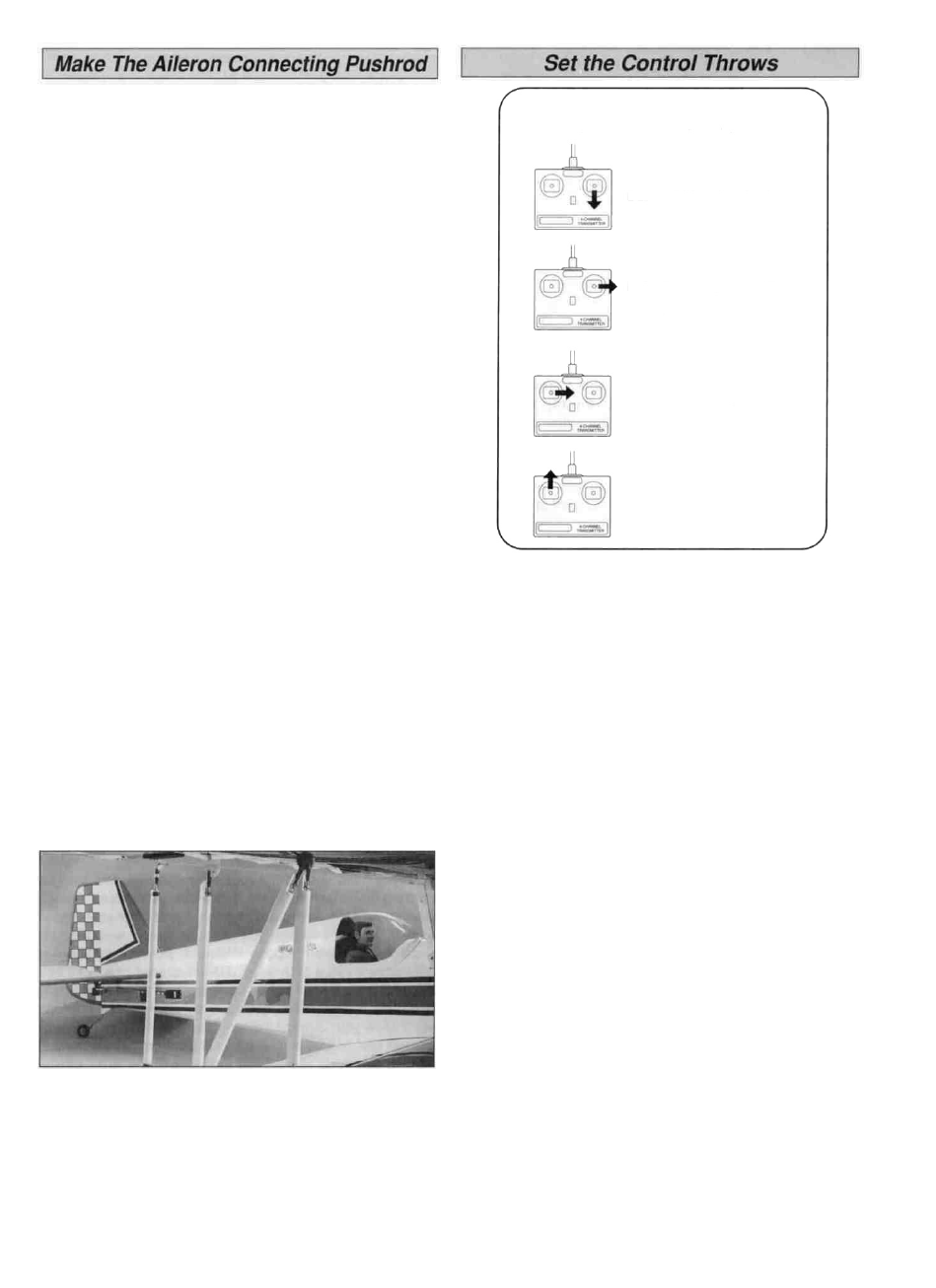

ELEVATOR MOVES UP

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

RUDDER MOVES RIGHT

CARBURETOR WIDE OPEN

The throws are measured at the widest part of the

elevators, rudder and ailerons Adjust the position of the

pushrods at the control/servo horns to control the

amount of throw You may also use the ATV's if your

transmitter has them but the mechanical linkages should

still be set so the ATV's are near 100% for the best servo

resolution (smoothest, most proportional movement)

Do not exceed the stated elevator throws.

We recommend the following control surface throws

High Rate

Low Rate

3/4" up

3/4" down

1-5/8" right

1-5/8" left

9/16" up

9/16" down

1-1/16" up

1-1/16" down

ELEVATOR:

RUDDER:

AILERONS:

2-1/8" right

2-1/8" left

3/4" up

3/4" down

NOTE If your radio does not have dual rates, set the

control surfaces to move between the high rate and low

rate throws

NOTE: The balance and control throws for the

Aeromaster have been extensively tested. This chart

indicates the settings at which the Aeromaster flies best.

Please set up your model to the specifications listed

above. If, after you become comfortable with your

Aeromaster, you would like to adjust the throws to suit

your tastes, that's fine. Too much throw can force the

plane into a stall or snap roll, so remember, "more is

not better."

4-CHANNEL RADIO SETUP

(STANDARD MODE 2)

45