Great Planes Giant Aeromaster Kit - GPMA0502 User Manual

Page 25

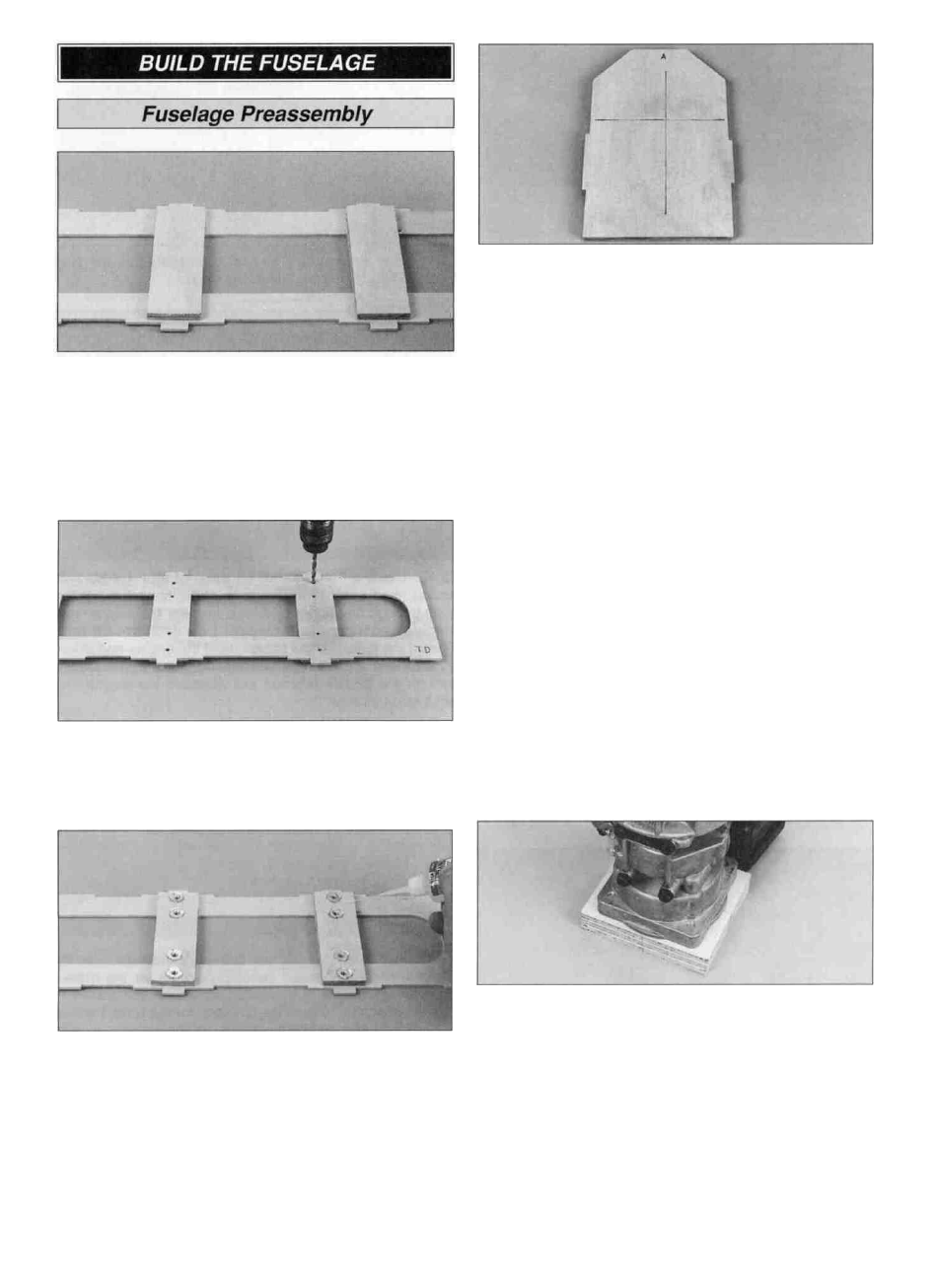

D 1. Use 6-minute epoxy to glue the shaped 1/4" x 1-1/2" x

4-1/2" ply cabane doublers to the top of the die-cut 1/8" ply

top deck (TD) centered between the tabs and the die-cut

holes. Note: The bottom side of the top deck features an

embossed (TD).

D 2. Drill a 5/32" hole at each punch mark through the top

deck and cabane doublers.

D 4. Draw centerlines connecting the punch marks on the

front of the die-cut 1/8" ply firewall (A). Use 30-minute

epoxy to glue firewall (A) to the shaped 1/4" ply firewall

doubler. Make sure the lines you previously drew are

facing forward and the bottom and edges of firewall (A)

and the firewall doubler are aligned. Wipe off the excess

epoxy before it cures.

Note: If firewall (A) and the firewall doubler are warped,

simply clamping them together may not "cancel out" the

warp. It is best to clamp the assembly to a table or a

flat board.

Important: We strongly recommend that any engine used

on the Giant Aeromaster be installed on an isolated shock

absorbing engine mount. The use of this type engine mount

will help prevent damage to the radio system and the

airplane frame due to engine vibration.

D 5. Skip ahead to step 10 if you will be installing the

recommended U.S. Engines 41cc engine and J'TEC

isolated engine mount on your Giant Aeromaster. If you are

not installing the isolated engine mount, use 30-minute

epoxy to laminate the three 1/4" x 3-1/4" x 3-3/4" ply

engine spacers together. If you will be installing a different

engine, center the engine on the firewall. The distance from

the firewall to the front of the drive washer needs to be

7-1/8" for the cowl to fit properly. Note: The following

instructions are based on the installation of the U.S.

Engines 41cc engine. Installation of your specific engine

may differ slightly.

D 3. Press a 6-32 blind nut into each hole. Use a 6-32 x

5/8" socket head bolt and #6 washer installed through the

cabanes to pull the blind nuts into the cabane. This will

ensure proper alignment of the cabanes and the blind nuts.

Add a few drops of thin CA around each blind nut flange to

secure them.

D 6. Use a ballpoint pen to draw centerlines on the engine

spacers. Extend the lines down the side of the spacers.

Center the engine on the spacers and mark the bolt hole

locations. The engine spacer is mounted with the shorter

dimension vertical. Drill and countersink a 1/4" hole at each

mark. Mount the engine to the spacer with 1/4-20 x 1-1/4"

flat head bolts (not included). During final assembly use

thread lock on the bolts to prevent loosening from vibration.

25