Great Planes Giant Aeromaster Kit - GPMA0502 User Manual

Page 36

D 6. Attach a solder clevis to the outermost hole in the

aileron servo arm. Center the aileron and the aileron servo

arm, then cut the aileron pushrod to the appropriate length.

Remove the aileron pushrod and the solder clevis from the

wing. Slide a silicone retainer on the pushrod then solder

the clevis on the end of the pushrod. Silver solder is highly

recommended. Reinstall the pushrod on the aileron servo

arm and the aileron control horn.

Some modelers prefer to install the pushrods and control

horns after the model is covered. If this is your preference

skip ahead to Assemble the Wheel Pants. Return to this

section after you have covered the model and joined the

control surfaces to the model with hinges.

D 7. Use a hobby knife to remove the area above the

bottom hole on two of the small control horns (as shown

in the drawing above). Use 2-56 x 5/8" screws and

backing plate to mount the control horn on the top TE of

the aileron and aligned with the slots for the strut tabs.

D 8. Repeat the process for the aileron in the other wing half.

D 9. If you are installing aileron servos in the top wing,

repeat the procedure for installing the aileron servos. If not,

use a hobby knife to trim two more of the small control

horns as before. Use 2-56 x 5/8" screws and backing plate

to mount the control horn at the TE of the aileron and

aligned with the slots for the strut tabs, on the top wing.

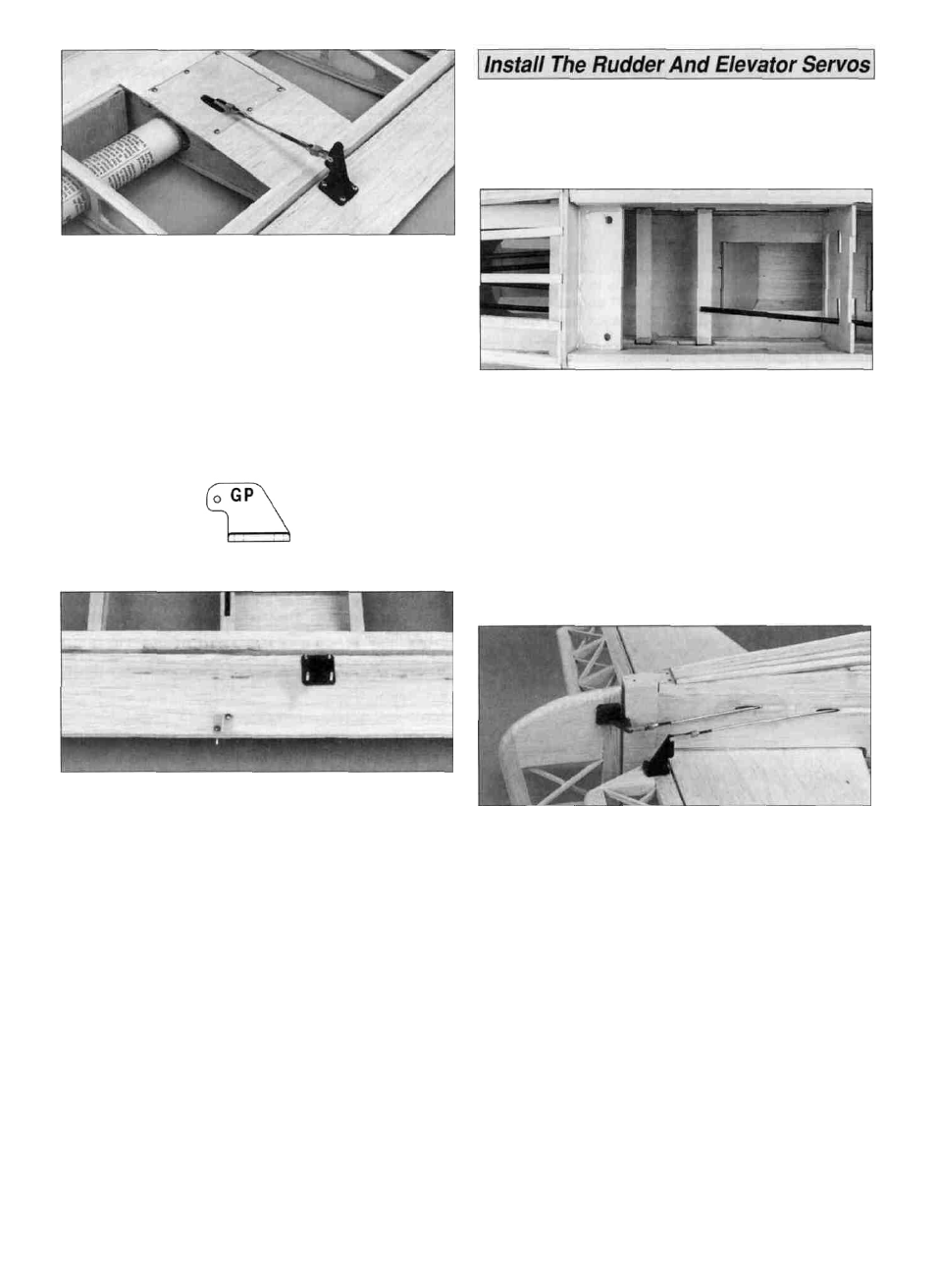

D 1. Cut the 1/4" x 1/2" x 10" basswood stick in half to

make the servo rails. Test fit the servo rails in the slots in

the fuselage doublers. Check that your servos will fit

between the rails. If not, slightly trim the slots in the

fuselage doubler. Use 6-minute epoxy to glue the servo

rails in the slots.

D 2. After the epoxy cures, cut the outer pushrod tubes so

that they are 1-1/2" back from the aft servo rail.

D 3. Thread three 4-40 nuts and metal clevises thirteen

complete turns onto three 4-40 x 36" threaded rods. Slide a

silicone clevis retainer over each clevis.

D 4. Attach a heavy duty control horn on each clevis. Insert

the pushrods into the rudder and elevator pushrod outer

tubes installed in the fuselage. Position the control horns on

the rudder and elevators so that the clevis holes are

aligned with the hinge joint. Mark the mounting holes and

drill 7/64" holes through the rudder and elevators, then

prick a few holes into the wood under the horn's location.

Apply a drop or two of thin CA to the pin holes to strengthen

the wood. When cured, attach the control horns with 4-40 x

1" machine screws and the backing plate.

D 5. Center the servo arms then position four servos on

the servo rails with the pushrods on the correct side of the

servos, as shown on the plans. Mark the servo mounting

holes and use servo mounting screws to attach the servos

to the servo rail. The servos for the rudder and elevator

must be high torque servos. The servo for the throttle can

be a standard servo.

36