Great Planes Giant Aeromaster Kit - GPMA0502 User Manual

Page 37

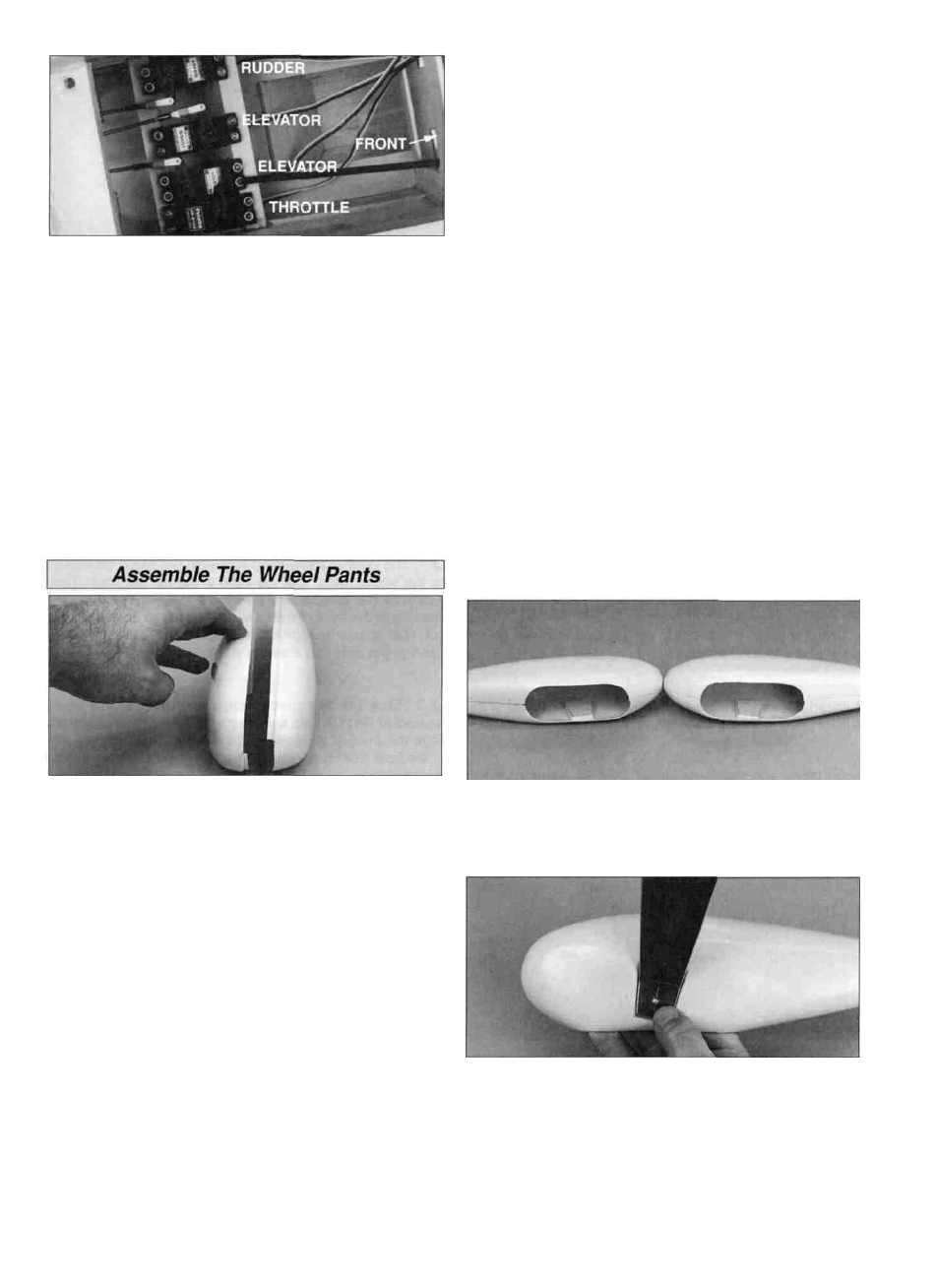

D D 3. Test fit the wheel pant halves and make

adjustments where necessary.

D D 4. Join the wheel pant halves by carefully spot gluing

them with thin CA. Glue the top, the front and then the rear

where the two halves butt together. After the halves are

joined, apply thin CA along the length of all seams.

D 6. Attach a solder clevis to the outermost hole in the

rudder and elevator servo arms. Center the rudder and

elevator servo arms on the servos. Cut the rudder and

elevator pushrods to the appropriate length. Remove the

pushrods and the solder clevis from the fuselage and slide

a silicone retainer on the pushrod, then solder the clevis on

the pushrod. Reinstall the pushrods and attach the clevises

to the servo arms and control horns.

Note: Do not use CA accelerator. Use of accelerator on the

ABS plastic may cause cracks and/or prevent paint from

adhering.

D 7. Position the tail wheel bracket on the bottom rear

deck. Mark the location of the tail wheel wire on the bottom

of the rudder. Remove the tail wheel wire and drill a 9/64"

hole at the mark. Test fit the tail wheel wire in the rudder.

The hole will be slightly larger than the wire. This allows the

epoxy to form a sleeve around the wire when it is glued in.

D D 5. Use your hobby knife or a power tool with a

sanding drum to cut out the wheel opening.

Hint: Make the wheel opening wide as this will make

installing the wheel and axle easier and cause less

interference with the wheel upon landing and takeoff. You

can see the size of the wheel opening in the following

photo.

D D 1. Trim one matching set of wheel pant halves along

the molded cut lines. Notice that the top of the outer pant

goes over the lip of the inner pant and the bottom of the

inner pant goes over the lip of the outer pant. You can use

a hobby knife to carefully score along the cut lines and flex

the plastic until the excess breaks free, or use small

scissors to cut along the lines. Kyosho curved Lexan

cutting scissors (KYOR1010) work extremely well for this

and make the job a cinch. For now, don't worry about

accurately cutting out the opening in each wheel pant half -

just cut an approximate opening for the wheels.

D D 2. Use your bar sander to carefully true the edges of

the overlapping pieces of the wheel pant halves so when

you glue them together the seam will be as small and

straight as possible. Notice that the rear of the pant halves

do not overlap. Use 150 or 220-grit sandpaper to remove

the flashing and thoroughly roughen all areas that are to

be glued, including the indentation on the inside of both

inner pant halves.

D D 6. Use medium CA to glue the die-cut 1/16" plywood

wheel pant mount to the inside of each wheel pant.

D D 7. Use a metal file to chamfer the edges and corners

of the aluminum landing gear so it will fit neatly in the

recess of the wheel pant. Position the wheel pant on the

aluminum landing gear. Use a felt-tip pen to accurately

mark the location of the axle mounting hole.

37