Great Planes Giant Aeromaster Kit - GPMA0502 User Manual

Page 40

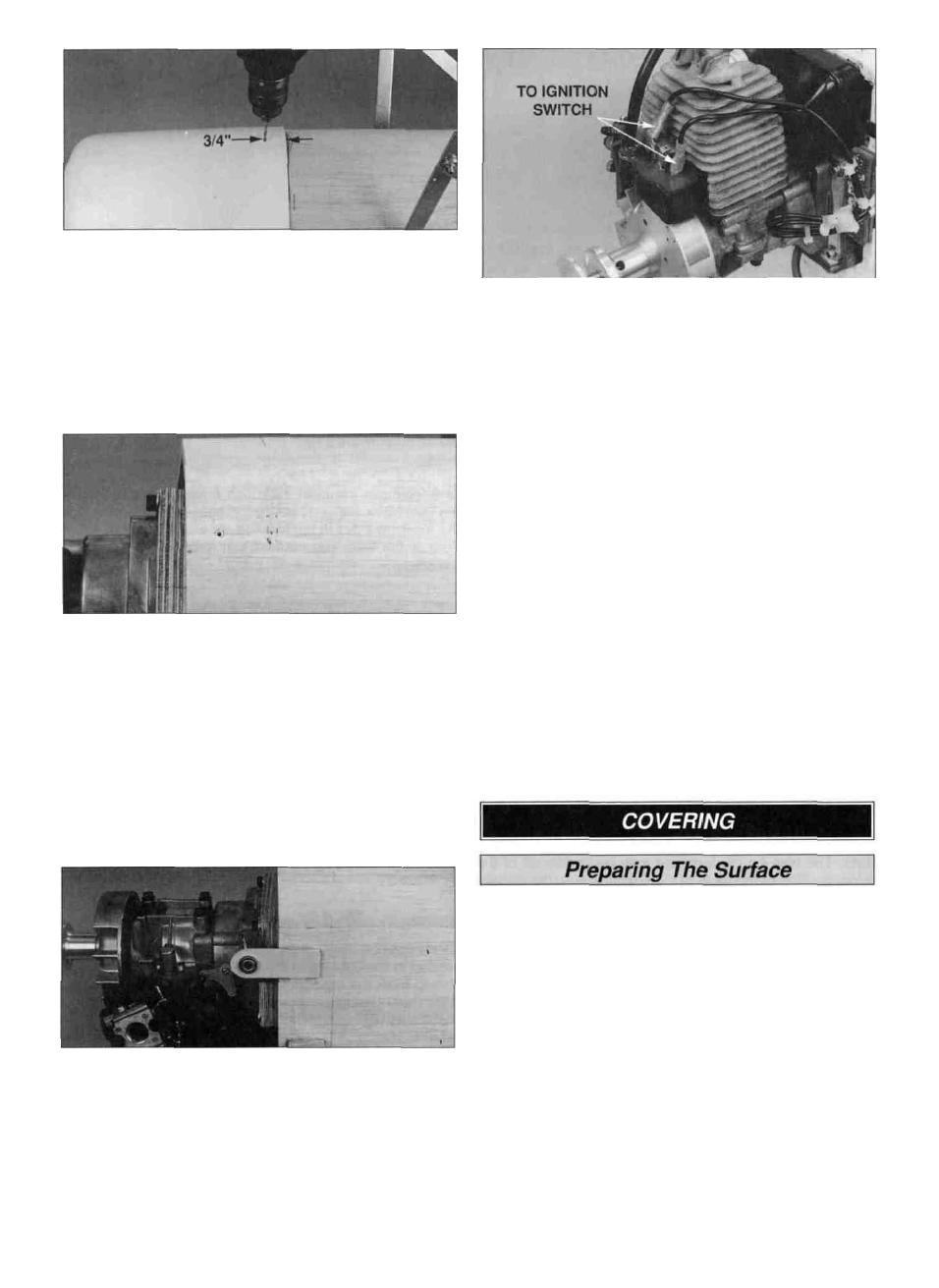

D 13. In the top of the cowl, drill a 3/32" hole through the

cowl and fuselage 3/4" from the aft edge of the cowl and

centered between the sides of the cowl.

D 14. Remove the cowl and enlarge the hole in the

fuselage to 1/8". From the 2" white inner pushrod tube,

cut a piece 1/2" long. Roughen the tube with 220-grit

sandpaper. Use medium CA to glue the tube into the hole in

the top of the fuselage.

D 16. If your Aeromaster will be powered by a gas engine,

an on/off switch must be installed on the engine. Gas

engines have a coil that generates electricity to produce a

spark. The on/off switch will prevent the engine from

starting accidentally. We connected a 5 amp/125 volt on/off

switch to the coil and mounted it on the side of the

fuselage.

Note: For additional strength, we recommend using

30-minute epoxy to apply a layer of fiberglass cloth (not

included) to the inside of the cowl over all joints.

D 17. Fill the seams or other imperfections in the cowl as

described in the preceding Wheel Pants section. Wet sand

the entire cowl with 400-grit sandpaper to prepare it

for priming.

D 1. If you've hooked up the pushrods to the servos before

you covered the model, disconnect and remove all the

control rods, hinges and control horns from the ailerons,

elevators and rudder. Remove the engine, cabanes, tail

wheel bracket and any other hardware you may

have installed.

D 15. On our prototype Giant Aeromaster we made a

mount for the Great Planes Easy Fueler (for gas) from

leftover 1/8" plywood, then securely glued it to the side of

the fuselage. We cut an access hole in the cowl for the

fueler using the template method.

D 2. Most of the model should be rough-sanded by now

with all the tabs and rough edges sanded even. Check the

cross-section views as you sand and round the edges. Fill

all dents, seams, low spots and notches with HobbyLite

balsa colored filler. (See expert tip that follows.)

40