Great Planes Giant Aeromaster Kit - GPMA0502 User Manual

Page 39

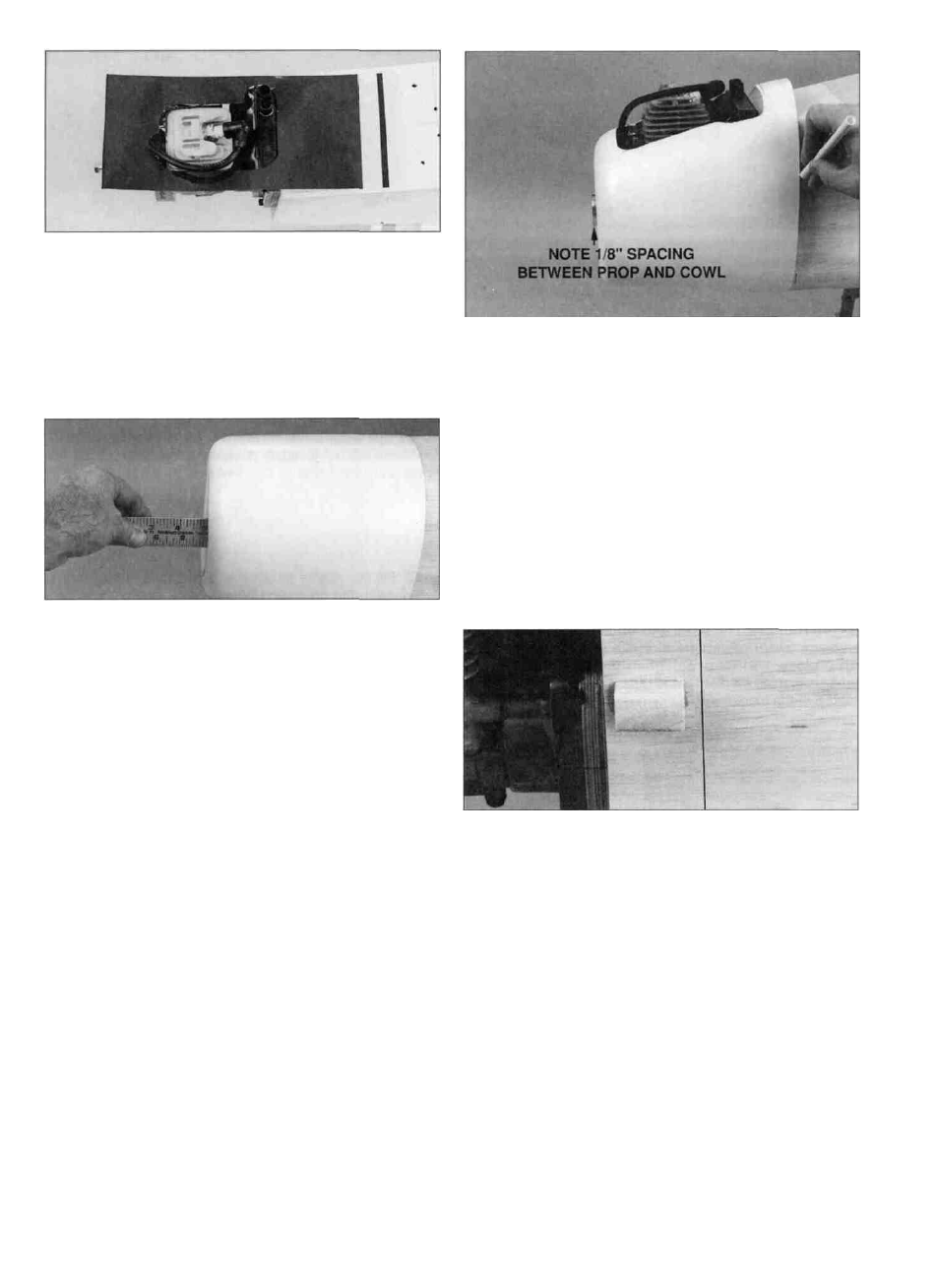

D 4. Reinstall the engine on the firewall. If the muffler hits

the fuselage balsa bottom blocks, trim the blocks so they

clear the muffler by at least 1/8". Use a piece of thin

cardboard or plastic to make a template for the cutout in the

cowl for the head of the engine and the carburetor. Tape

the template to the fuselage side accurately indicating the

position of the head.

D 8. Drill a hole that is slightly larger than the crankshaft,

through the center of a flat stick. Mount the stick tight

against the drive washer on your engine. With the drive

washer centered at the front of the cowl, align the cowl so

there is approximately 1/8" clearance between the stick and

the cowl. Use a ballpoint pen to mark the fuselage sides at

the aft edge of the cowl.

D 9. Remove the cowl, then use 6-minute epoxy to glue

the two 1/2" x 5/8" x 1" hardwood cowl mounting blocks to

the fuselage sides in the location shown on the plan 1/4" in

front of the lines you marked that indicate the aft end of

the cowl.

D 5. Measure the distance between the firewall and the front

of the drive washer (it should be 7-1/8"). Remove the engine

from the fuselage. Then position the cowl on the fuselage so

the forward edge is 1/8" aft of the measurement you just

made. Use a ballpoint pen to lightly mark the location of the

rear of the cowl on the fuselage top.

D 6. Align the cowl with the mark you made on the

fuselage. Then use a felt-tip pen to transfer the hole in the

template onto the cowl.

Note: The hole on the template may be slightly aft of the

actual position of the head of the engine due to the upward

sweep of the template when the cowl is in position.

D 7. Remove the cowl and template, then remount the

engine. Cut the hole in the cowl and test fit it on the

fuselage. You may want to make the cuts slightly forward of

the template outline to allow for the upward sweep of the

template. Adjust the position and size of the hole as

needed. The location of the hole determines the clearance

between the front of the cowl and the back of the prop.

D 10. Shape the cowl mount blocks with your bar sander

and 150-grit sandpaper to match the shape of the cowl.

Test fit the cowl and make adjustments to the blocks

if necessary.

D 11. Position the cowl on the fuselage, centering the drive

washer in the opening in the front of the cowl. Use a felt-tip

pen to mark the cowl for the cowl mounting screws. Drill a

3/32" hole through the cowl and cowl mounting blocks at

the marks. Remove the cowl and enlarge the holes in the

cowl to 9/64".

Hint: Cut the hole in the cowl slightly undersize at first so

you can make adjustments to its position.

D 12. Mount the cowl to the fuselage with two #6 x 1/2"

button head screws and two #6 washers supplied with

this kit.

39