6regulations, 1 machine status, 2 controlling the functioning mode – EVCO c-pro nano NAV User Manual

Page 23: 3 set point

C-PRO NANO AND MICRO NAV APPLICATION MANUAL

Page 23

6

REGULATIONS

6.1

Machine status

Procedure doe switch-on/off of the unit using the relative On/Off key:

Switch-on -

press the relative key for about 2 seconds: the machine goes to "ON" and

displays the average temperature of the input fresh water of the connected units.

Switch-off - press the relative key for about 2 seconds: the machine goes to "OFF".

The machine On/Off key is the ESC key.

During the ON state, the consent input of every unit enables them for regulation.

The slave units cannot function without any master, therefore the switch-on/off of the master also

causes the switch-on/off of the slaves. (The units connected will be switched-off in a delayed

sequence in order to prevent the simultaneous closure of all compressors that are on at that time)

6.2

Controlling the functioning mode

The operational mode can assume the following values:

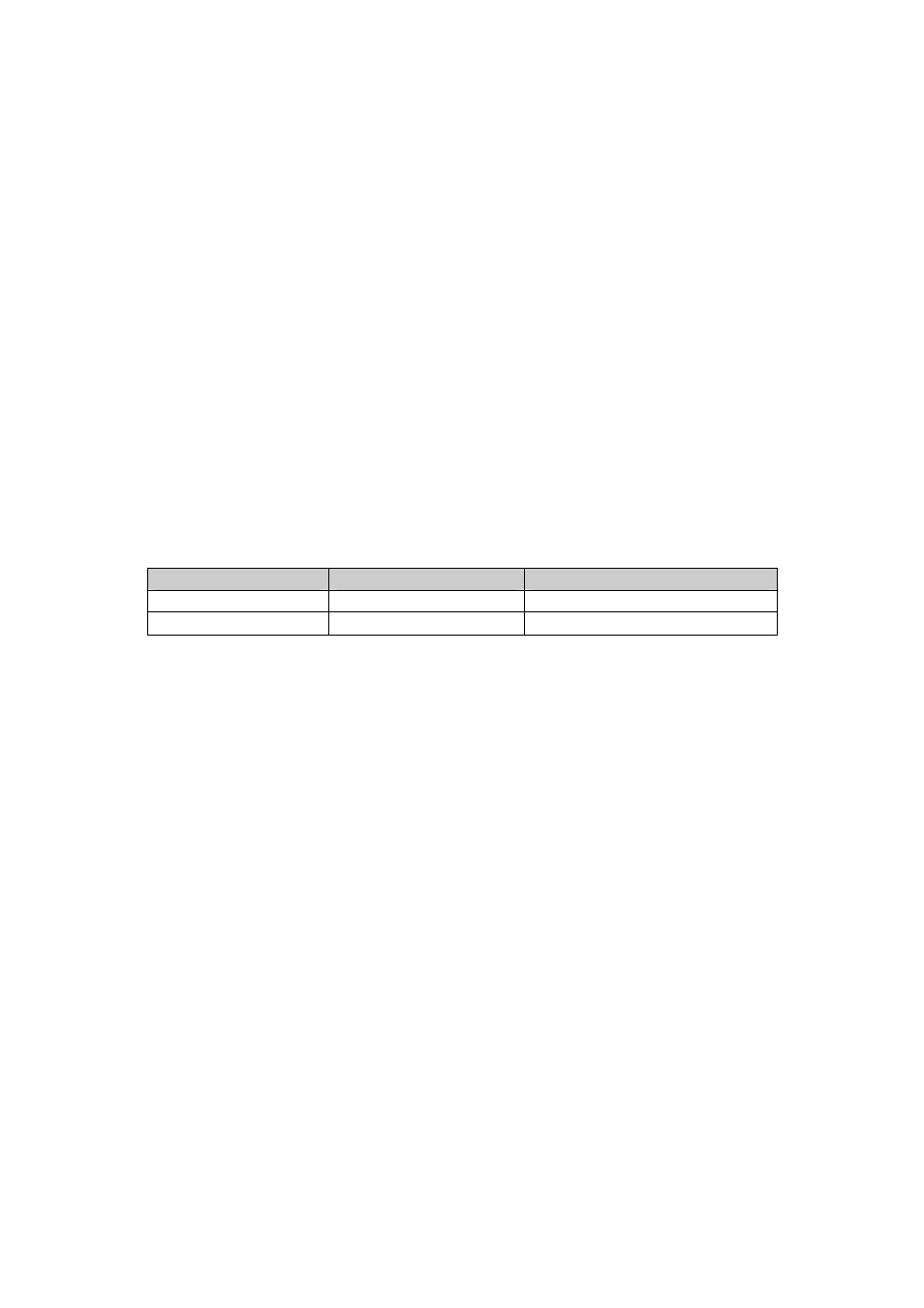

“SEAS” status

Operational mode

Description

Off=0=COLd

Chiller

Summer functioning mode

On=1=HEAt

Heat Pump

Winter functioning mode

To modify the unit functioning mode, act using the Change over command from digital input DI2

(coming from the manual selector switch of the master on the electric control board). The units do

not have this digital input, the information regarding the functioning mode is communicated by the

master via CAN.

Setting: With closed contact the unit is in "winter" functioning mode, with open contact it is

in "summer" mode.

During winter functioning mode (Heat Pump) the DO6 cycle reverse valve is activated on the unit.

Warning - The variation of the operational mode can also take place with the machine on: in this

case, the machine switches off respecting its timing and therefore changes over and switches back

on again automatically.

6.3

Set Point

The Set Point is set on the master and then sent to all slave units connected to the network.

This set point is updated systematically in the slaves and saved as parameter. In this way, also after

any blackout or during network breakdown persistent data is guaranteed for regulation of the unit.

This set point is the same for the calculation of the steps (based on the average temperature of the

input fresh water) and for the regulation of the compressor (based on the output fresh water) in the

regulation of the SET compressor is "adjusted" thanks to the delta heat drop (dEL parameter) to

balance the temperature difference of the input and output water.